Refrigerating cycle device

A technology of circulation device and throttling device, which is applied in the direction of cooling fluid circulation device, household refrigeration device, irreversible cycle compressor, etc. It can solve the problems of catalyst activity reduction, corrosion of sensor components, detection sensor sensitivity drop, etc., to prolong life , the effect of environmental protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

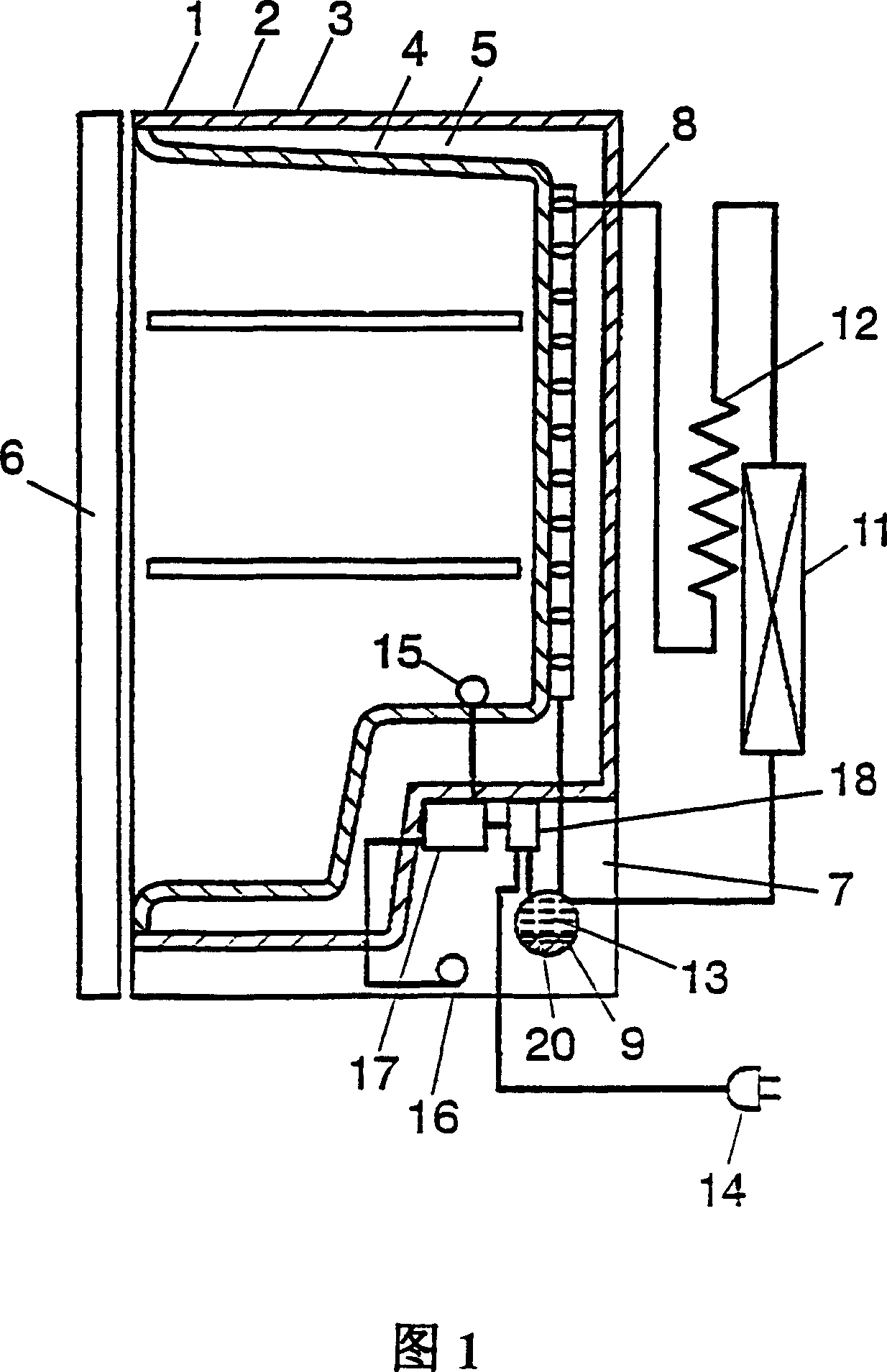

[0021] Fig. 1 is a sectional view of a refrigerator according to an embodiment of the present invention. In FIG. 1, the refrigerator of the present invention uses silicone-free lubricating oil 20. Referring to FIG.

[0022] The operation of the refrigerator in the structure of the present invention will be described below.

[0023] Once the compressor 9 is operated by supplying power from the power outlet 14, the flammable hydrocarbon refrigerant 13 is ejected from the compressor 9, becomes high temperature and high pressure, and condenses and liquefies in the condenser 11 through heat exchange with outdoor air. Next, it becomes low temperature and low pressure in the throttling device 12 , exchanges heat with the refrigerator in the evaporator 8 , vaporizes, and then returns to the compressor 9 to repeat the refrigeration cycle to circulate the hydrocarbon refrigerant 13 . At this time, a little lubricating oil 20 in the compressor 9 also circulates together with the hydroca...

Embodiment approach 2

[0027] Fig. 2 is a cross-sectional view of a refrigerator according to Embodiment 2 of the present invention. In FIG. 2, the refrigerator of the present invention has detachable gas detection sensors 21 and 22 while using lubricating oil 20' containing silicone.

[0028] The operation of the refrigerator of the present embodiment is the same as that of the first embodiment.

[0029] According to the present embodiment, the hydrocarbon refrigerant 13 leaks from the refrigeration cycle, and the silicone-containing lubricating oil 20 ′ that becomes mist together with the hydrocarbon refrigerant 13 leaks near the gas detection sensors 21 and 22 and adheres to the gas. On the detection sensors 21 and 22, when gas detection cannot be performed in the future, new sensors can be replaced. Thereby, the refrigerator can be used safely again. In addition, when the sulfide floats near the gas detection sensors 21, 22 and corrodes the gas detection sensors 21, 22, making subsequent detec...

Embodiment approach 3

[0031] Fig. 3 is a cross-sectional view of a refrigerator according to Embodiment 3 of the present invention. The refrigerator of this embodiment has filters 23 and 24 for removing siloxane, and the filters 23 and 24 for removing siloxane are attached so as to cover the gas detection sensors 15 and 16 .

[0032] The operation of the refrigerator of the present embodiment is the same as that of the first embodiment.

[0033] In the refrigerator of the present embodiment, even if lubricating oil 20 ′ containing siloxane leaks near the gas detection sensors 15 and 16 , and adheres to the gas detection sensors 15 and 16 , it becomes misty with the hydrocarbon refrigerant 13 The gas detection sensor can also be protected by previously removing siloxane with filters 23 and 24 for removing siloxane. In addition, in the refrigerator of the present embodiment, if siloxane exists in the ambient atmosphere around the gas detection sensor due to not only leakage of the refrigerant from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com