Catalyst for olefin polymerization and method for polymerization of olefin

A technology of olefin polymerization and catalyst, applied in the field of olefin polymerization, can solve problems such as long-term polymerization operation difficulties, insufficient polymerization activity, composition deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

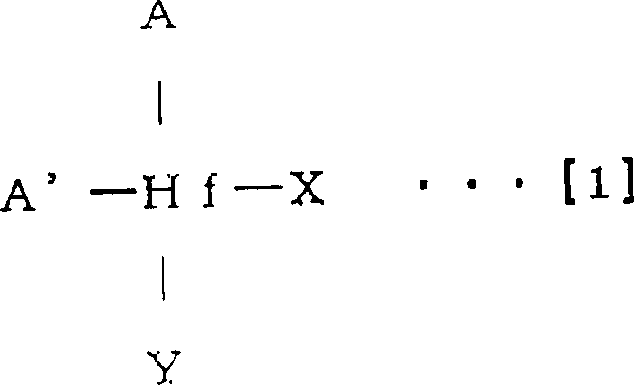

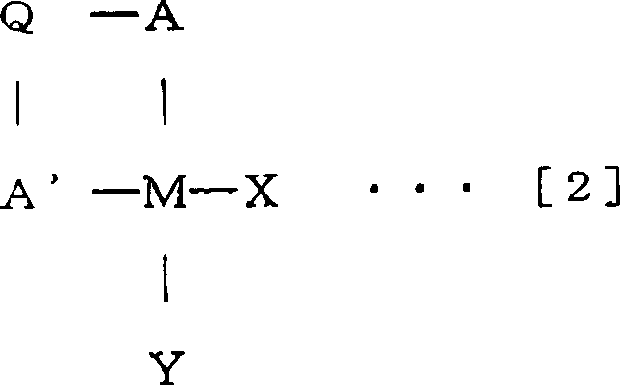

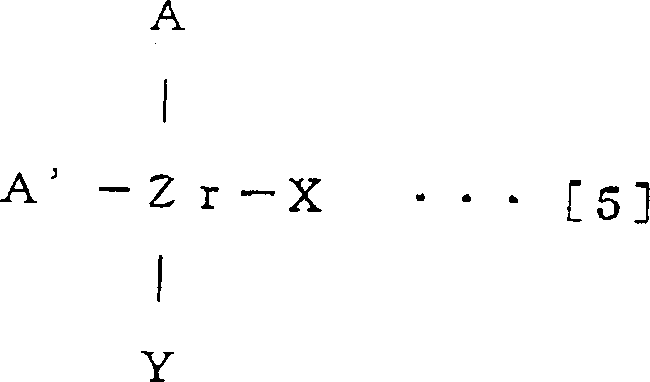

Method used

Image

Examples

Embodiment 1

[0207] (1) Acid treatment of clay minerals

[0208] Disperse 37 kg of commercially available granulated and graded swelling montmorillonite (Benclair SL, manufactured by Mizusawa Chemical Co., Ltd., with an average particle diameter of 27 μm) in 148 kg of 25% sulfuric acid, stir at 90° C. for 2 hours, and filter with desalted water ,washing.

[0209] (2) Titanium salt treatment and drying of clay minerals

[0210] In the commercially available titanium sulfate aqueous solution (Chemical Industry Co., Ltd.), containing TiO 2 7.5%, including SO 4 25.6%) in 236kg, the montmorillonite filter cake obtained in the above (1) through the sulfuric acid treatment was all dispersed, and stirred for 3 hours at 30°C. After filtering it with desalinated water and washing it to pH 3.5, the resulting water-containing solid filter cake was pre-dried at 110° C. for 10 hours to obtain titanium salt-treated montmorillonite. The particles passing through the 150 mesh sieve in the pre-dried mon...

Embodiment 2

[0218] In addition to using bis(1-n-butyl-3-methylcyclopentadienyl) zirconium dichloride (0.48mmol, that is, a solution of 0.2076g dispersed in n-heptane 69.2ml) as component [A2] and bis( n-Butylcyclopentadienyl) hafnium dichloride (1.92mmol is the solution of 0.9442g dispersed in n-heptane 314.7ml) as the component [A1], and the same method as in Example 1 (3) (4) to prepare the preliminary polymerization catalyst to obtain 79.2 g of preliminary polymerization catalyst powder. Using this preliminary polymerization catalyst powder, ethylene-1-hexene copolymerization was carried out in the same manner as in Example 1 (5). The polymerization results are shown in Table 1, and the product properties are shown in Table 2.

Embodiment 3

[0224]In addition to using bis(1,3-dimethylcyclopentadienyl)zirconium dichloride (1.20mmol, that is, a solution of 0.4181g dispersed in n-heptane 139.4ml) as component [A2] and bis(n-butylcyclopentadienyl) Dienyl) hafnium dichloride (1.20mmol is the solution that 0.5902g is dispersed in n-heptane 196.7ml) as component [A1], prepares the prepolymerization catalyst with the same method as embodiment 1 (3) (4), obtains Prepare 75.8 g of polymerization catalyst powder. Using this preliminary polymerization catalyst powder, ethylene-1-hexene copolymerization was carried out in the same manner as in Example 1 (5). The polymerization results are shown in Table 1, and the product properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com