Powder coating composition, process for producing the same and coating film made from the same

A technology of powder coatings and manufacturing methods, applied in the direction of powder coatings, devices for coating liquid on surfaces, coatings, etc., can solve such problems that have not been developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Add 665g of aluminum powder for powder coating manufactured by Toyo Aluminum Co., Ltd. (PCF 7640, D50 = 19 μm: D50 is the average particle diameter, about 0.1 g of the sample is dispersed in 5 g of an aqueous solution of 0.5% Triton X (manufactured by UNION CARBIDE, surfactant), water is used as the solvent, and it is dripped into Microtrac 9320 X-200 manufactured by Honeywell Co., and after ultrasonic dispersion (40W 10 seconds), the value measured.), and 7000 g of polyester resin powder (Teodur PE 785-900 D50 manufactured by Kubo Kao Paint Co., Ltd. = About 49 μm), stir and mix for 10 minutes.

[0082] Then, 105 g of terpane-phenol hydrogenated resin (Clearon P-105 manufactured by Yasuhara Chemical Co., Ltd., number average molecular weight 650, softening point 105° C.) was dissolved in 350 g of heptane (boiling point 98.4°C) to form a binder solution, which was then added to the above-mentioned mixed solution of aluminum powder and resin powder, and stirred for 20 m...

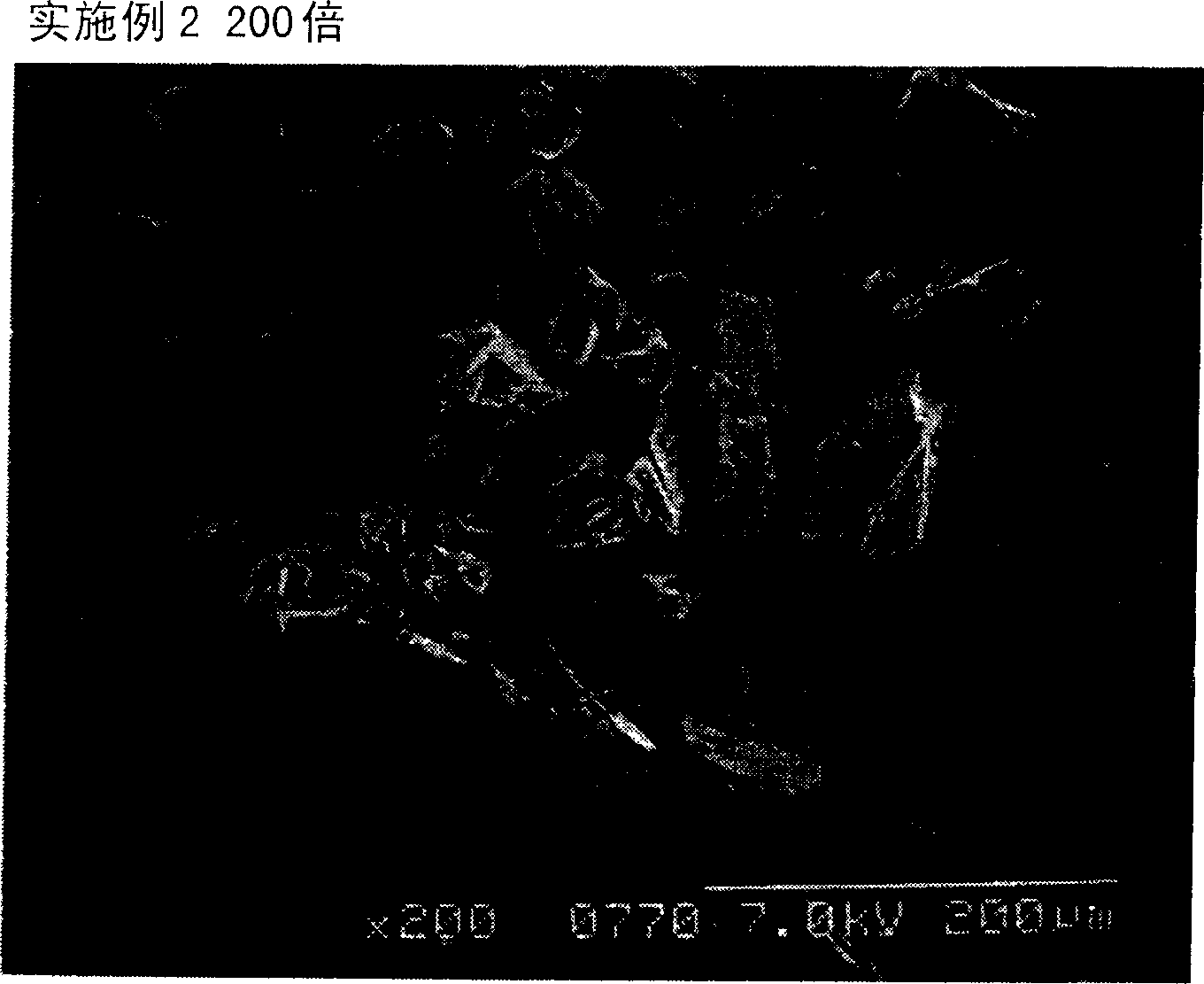

Embodiment 2

[0084] 8.6 g of aluminum powder for powder coating (PCF1401, D50 = 60 μm) manufactured by Toyo Aluminum Co., Ltd. and 108.3 g of polyester resin powder (Teodur PE 785-900 D50 = about 49 μm manufactured by Kubo Kao Paint Co., Ltd.) were mixed in 1 Mix well in a PP cup.

[0085] Adhesive adhesives were formed by dissolving 3.1 g of terpane hydrogenated resin (Clearon P-105 manufactured by Yasuhara Chemical Co., Ltd., number average molecular weight 650, softening point 105° C.) in 31.3 g of heptane agent solution, and then added to the above-mentioned mixture of aluminum powder and resin powder, while fully mixing and stirring, while heating with a 40°C water bath from time to time to evaporate the heptane. When the wet powder was almost dry, it was transferred to an eggplant-shaped flask and dried in a rotary evaporator at 40°C for 20 minutes under vacuum to completely evaporate the heptane. The obtained resin powder was passed through a 100 μm sieve to obtain 113.6 g of bonde...

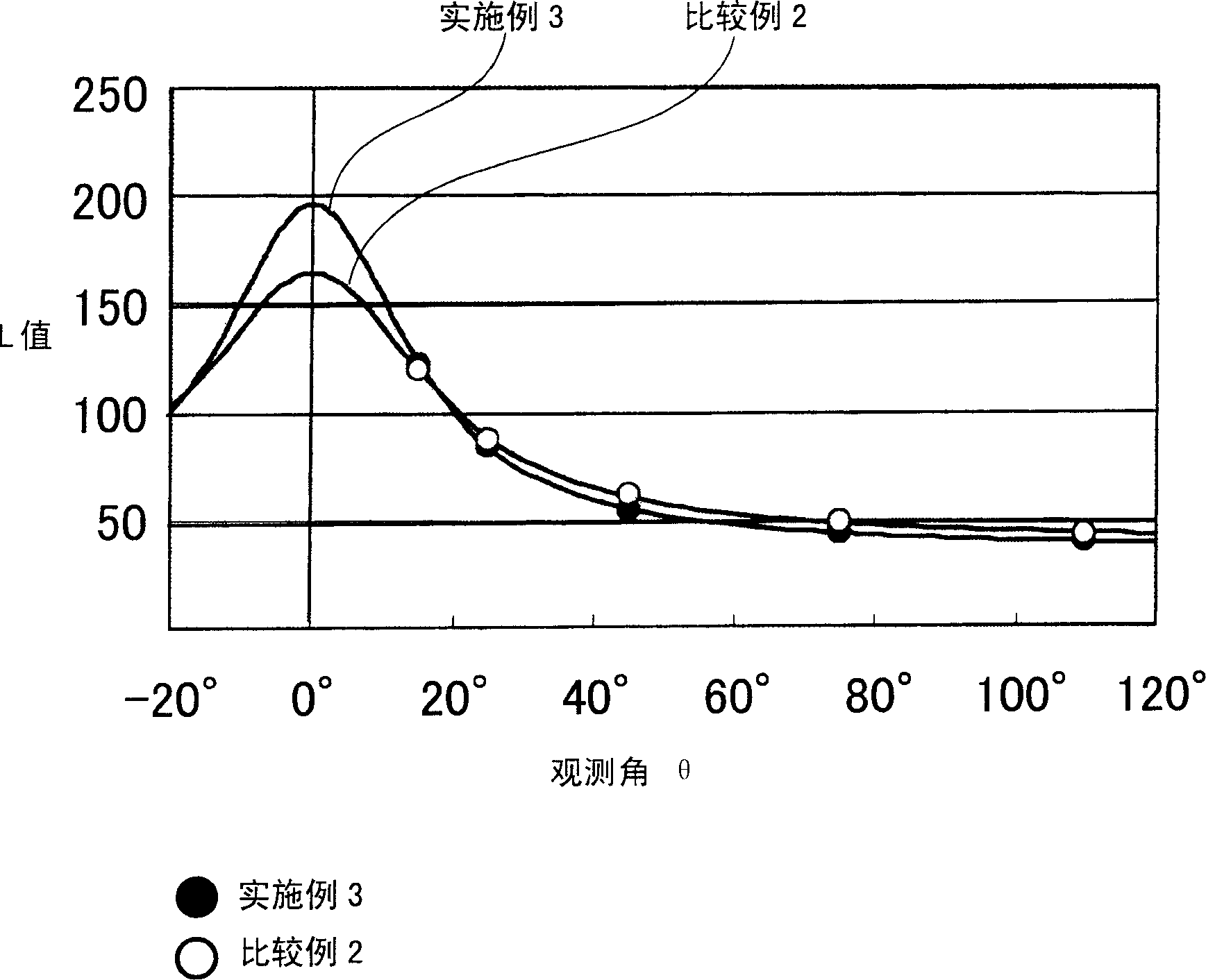

Embodiment 3

[0087] Bonded aluminum was obtained in the same manner as in Example 2 using an aluminum powder for powder coating (PCF1440A, D50=34 μm) manufactured by Toyo Aluminum Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com