Flexographic ink containing polymer or copolymer of 3,4-dialkoxythiophene

A dialkoxythiophene, offset printing ink technology, applied in the direction of ink, organic material conductor, printing, etc., can solve the problems of ink can not be combined, opaque printed matter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

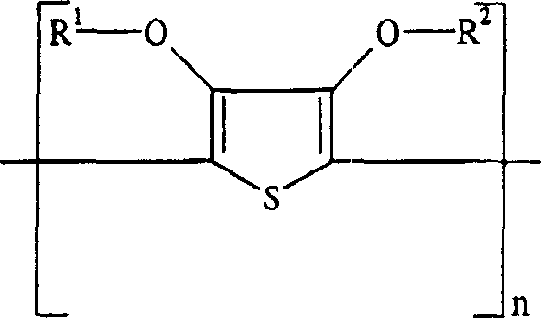

[0051] According to a first embodiment of the offset printing ink according to the invention, the offset printing ink contains at least 0.2% by weight of a polymer or copolymer of 3,4-dialkoxythiophene, where the two alkoxy groups can be the same or different, or together denotes an optionally substituted oxy-alkylene-oxy-bridge.

[0052] According to a second embodiment of the offset printing ink according to the invention, the offset printing ink contains at least 0.3% by weight of a polymer or copolymer of 3,4-dialkoxythiophene, wherein the two alkoxy groups can be the same or different, or together denotes an optionally substituted oxy-alkylene-oxy-bridge.

[0053] According to a third embodiment of the offset printing ink according to the invention, which is reproducible after stirring to a constant viscosity, ie until successive measurements according to DIN 53211, the viscosity at 25° C. measured according to DIN 53211 is at least 100 mPa·s.

[0054] According to a fou...

no. 7 approach

[0058] According to a seventh embodiment of the flexographic ink of the invention, the polymer or copolymer of 3,4-dialkoxythiophene has the following formula:

[0059]

[0060] Among them, R 1 and R 2 Each independently represents hydrogen or C 1-5 Alkyl or together represent optionally substituted C 1-5 Alkylene or cycloalkylene.

[0061] According to an eighth embodiment of the flexographic ink of the present invention, the polymer or copolymer of 3,4-dialkoxythiophene is one in which two alkoxy groups together represent an optionally substituted oxy-alkylene-oxy Bridged polymers or copolymers of 3,4-dialkoxythiophenes.

[0062] A ninth embodiment of the offset printing ink according to the invention, wherein the two alkoxy groups together represent an optionally substituted oxy-alkylene-oxy bridge polymer or copolymer of 3,4-dialkoxythiophene Compounds selected from: poly(3,4-methylenedioxythiophene), poly(3,4-methylenedioxythiophene) derivatives, poly(3,4-ethylene...

no. 1 approach

[0225] According to a first embodiment of the method according to the invention, the method further comprises the step of adding at least one organic compound containing di- or poly-hydroxy and / or carboxyl or amide or lactam groups, for example sugar alcohols such as sorbose alcohol, mannitol, sucrose and fructose, diethylene glycol, 1,2-propanediol, propylene glycol, N-methylpyrrolidone, and the conductive coating obtained therefrom is tempered to increase its resistance to preferably <300 ohms / square, as disclosed in EP-A 686 662, incorporated herein by reference.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com