Waste gas treatment system for paint drying oven

A waste gas treatment and drying furnace technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of increasing furnace temperature, increasing energy consumption, and not treating waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

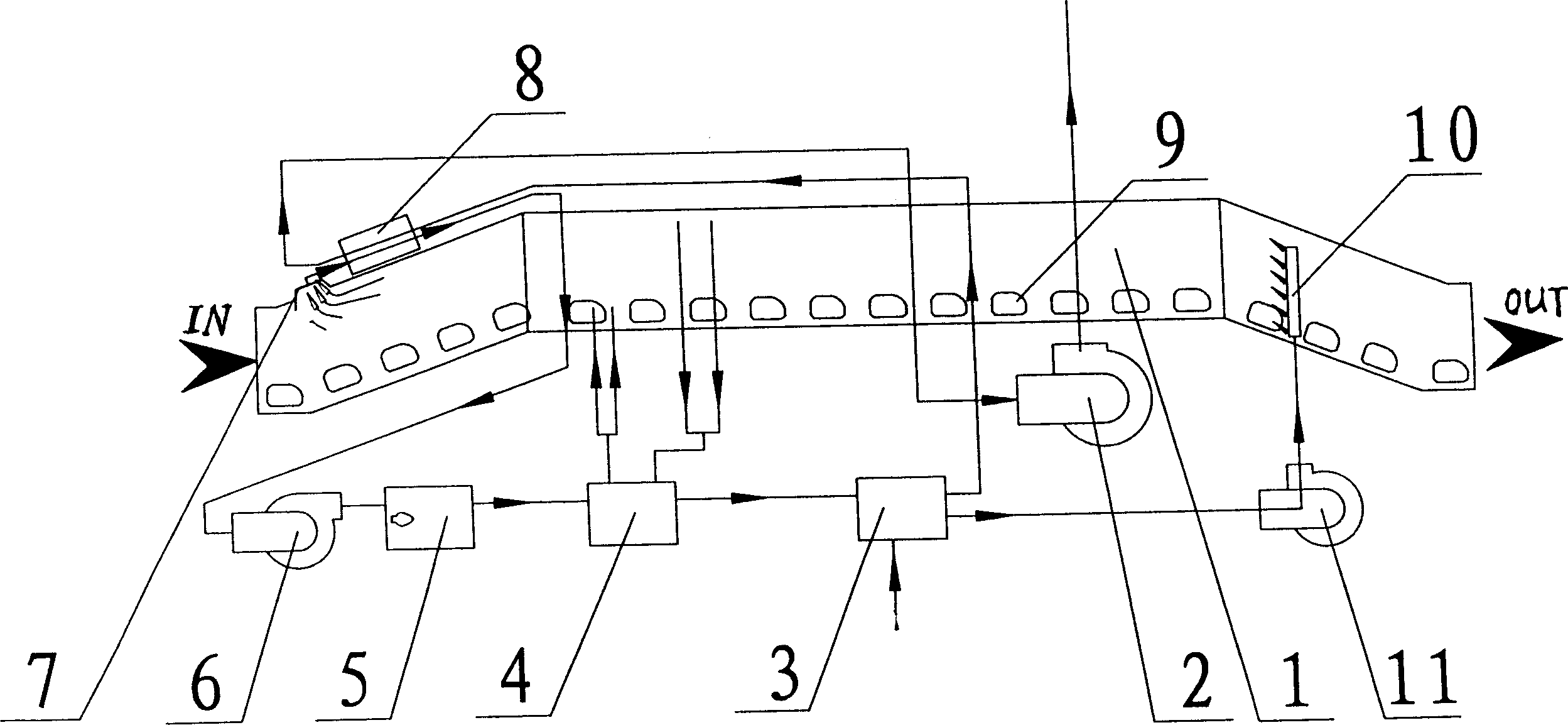

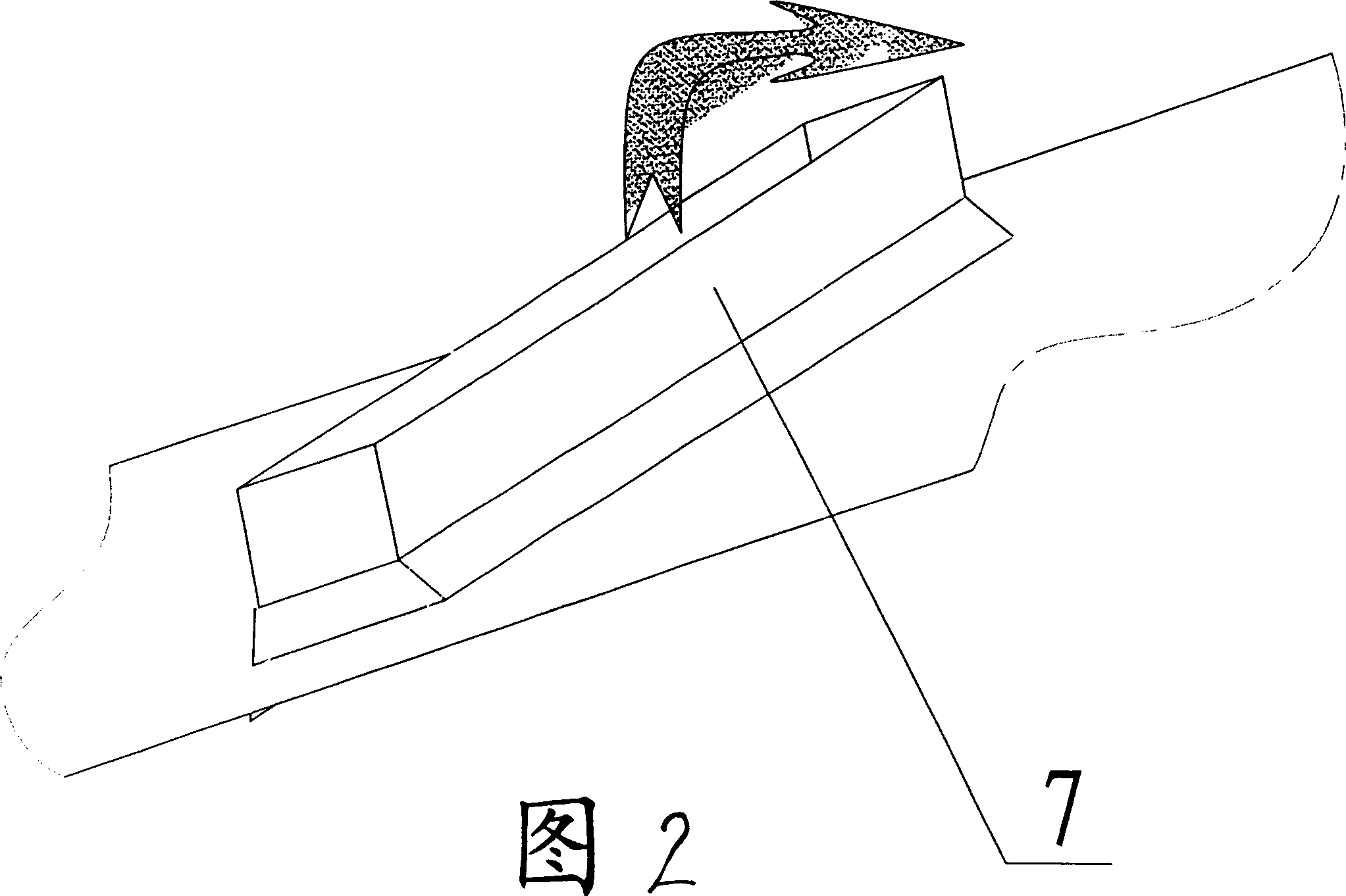

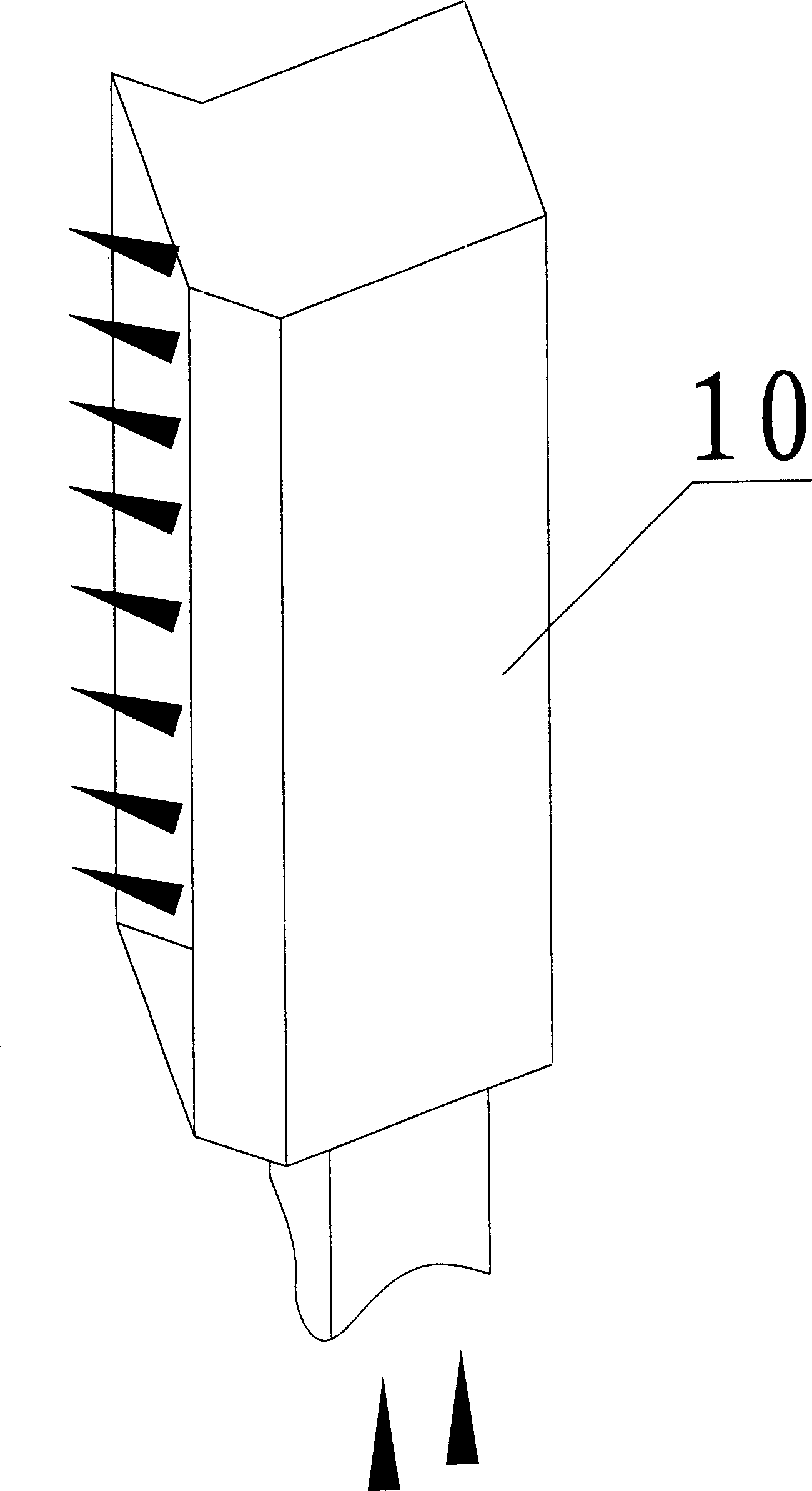

[0027] In this embodiment, fresh air first passes through the air-flue gas heat exchanger 3 and enters the air outlet 10 at the product outlet OUT through the heat machine 11, and the air runs along the inner channel of the drying furnace 1 to the exhaust hood at the product inlet IN. 7. The exhaust gas then enters the exhaust gas-flue gas heat exchanger 8 and then enters the incinerator 5 through the exhaust gas exhaust fan 6. After being incinerated at high temperature, the exhaust gas becomes flue gas and enters the air in multiple furnaces—the flue gas of the flue gas heat exchanger 4 Enter the exhaust gas-flue gas heat exchanger 8 flue gas pipes on the top of the drying furnace shell again, and then turn back to the high-pressure exhauster 2 to empty. 0~15 meters of the product outlet OUT end are provided with an air supply port 10, and the air supply port 10 is a tubular body with several oblique openings that enters the air from the bottom and blows out from the side to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com