Flue gas pollutant removal system suitable for small-scale unit

A pollutant, small-scale technology, applied in the field of flue gas pollutant removal system, can solve the problems of large floor space, high energy consumption, complex process route, etc., to achieve the effect of high-efficiency filtration, avoid contact, and reduce equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

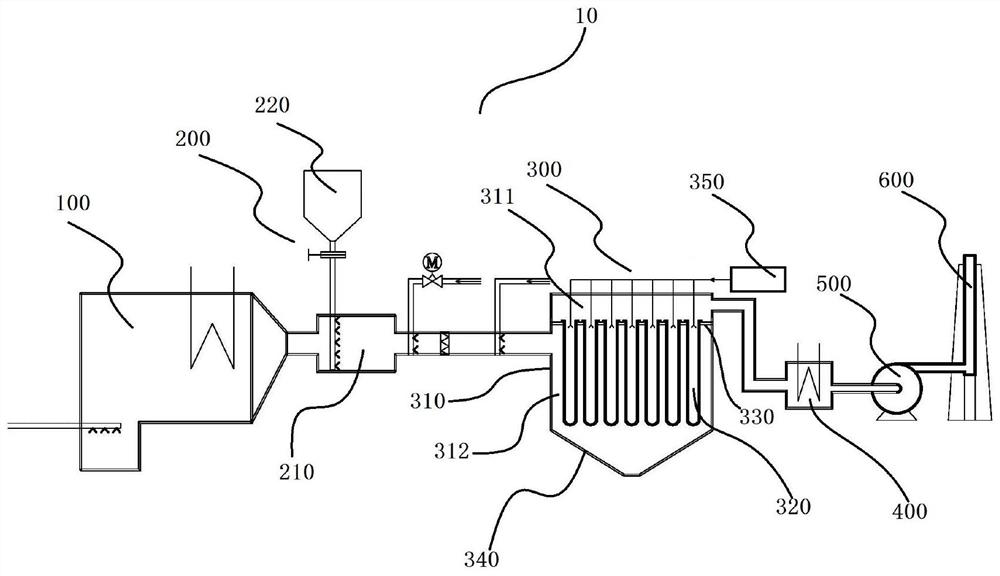

[0028] The present invention provides a flue gas pollutant removal system 10 suitable for small-scale units such as figure 1 As shown, the system includes a boiler 100 , a desulfurization absorption device 200 , a dust and nitrate filter device 300 , a waste heat recovery device 400 , an induced draft fan 500 and a chimney 600 connected in sequence through pipelines. In small-scale units such as biomass power plants and garbage power plants, under the action of induced draft fans, the flue gas produced by the boiler first goes through the desulfurization absorption device for dry desulfurization or semi-dry desulfurization, and then enters the dust filter device for dust, Simultaneous removal of nitrogen oxides. After removing flue gas pollutants, the flue gas passes through the waste heat recovery device to recover waste heat, and finally is discharged from the chim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com