Production method of crystal alum

A production method and crystal technology, applied in the field of crystal alum production, can solve problems such as slag not being reused, materials not seen, serious losses, etc., and achieve the effects of being beneficial to environmental protection, reducing pollution, and improving output and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

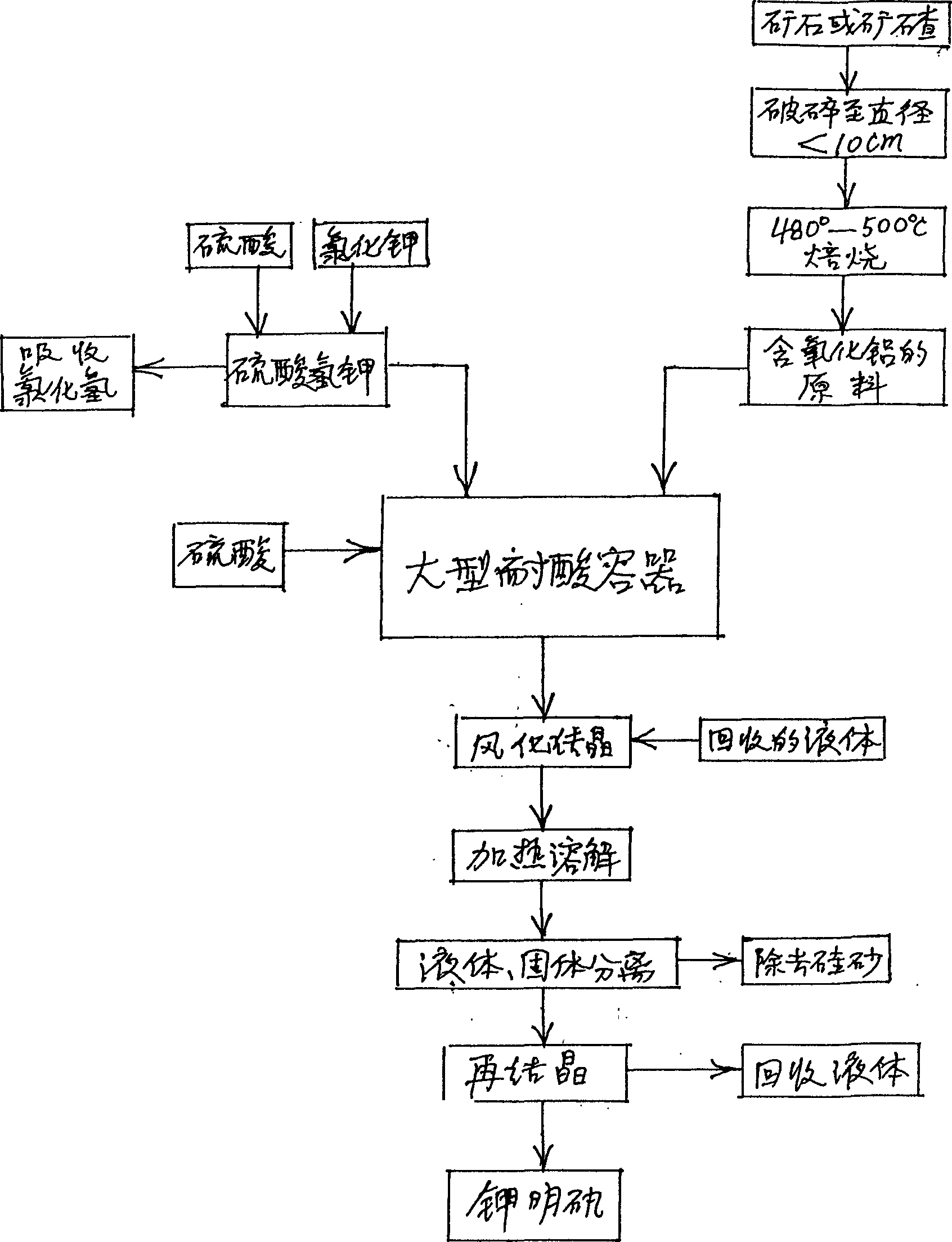

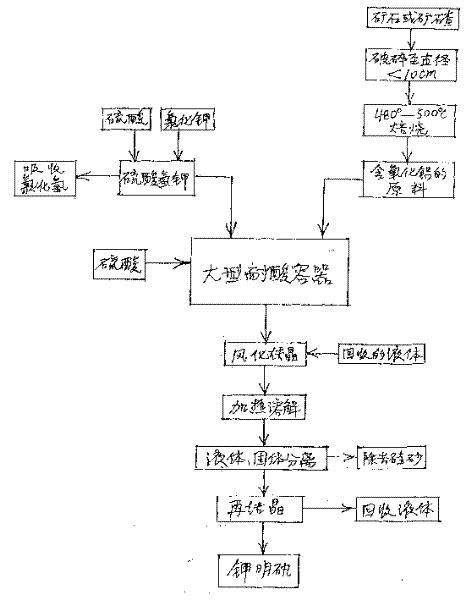

Embodiment 1

[0021] Get 15 tons of potassium alunite slag with an alumina content of 10%, and put it in a large acid-resistant container; take another 2 tons of potassium chloride for industrial use and add 2.5 tons of 95% sulfuric acid in a smaller acid-resistant container, and the hydrogen chloride gas produced will absorb and transfer Go, put the obtained potassium bisulfate together with excess sulfuric acid into a large acid-resistant container, add 2.75 tons of 95% sulfuric acid, after fully reacting to form aluminum potassium sulfate, add an appropriate amount of water to weather at room temperature, pass in steam, and heat to 95°C Make it dissolve, separate the liquid from the solid residue, and remove the solid residue. At this time, the solid residue is mainly silica sand. The obtained liquid is recrystallized, and the crystal potassium alum product is taken out. The liquid after taking out the crystals can be placed in a large acid-resistant container, so that the recovered liqui...

Embodiment 2

[0023] Get 15 tons of potassium alunite slag with an alumina content of 10%, put it in a large acid-resistant container; get another 2 tons of potassium chloride for industrial use, add 2.5 tons of 98% sulfuric acid in a smaller acid-resistant container to absorb and remove it, Put the obtained potassium bisulfate together with excess sulfuric acid into a large acid-resistant container, add 2.75 tons of 98% sulfuric acid; after fully reacting to form aluminum potassium sulfate, add appropriate amount of water to weather at room temperature, pass in steam, and heat to 98°C to make it Dissolving, following steps are identical with embodiment 1, obtain crystal potassium alum product.

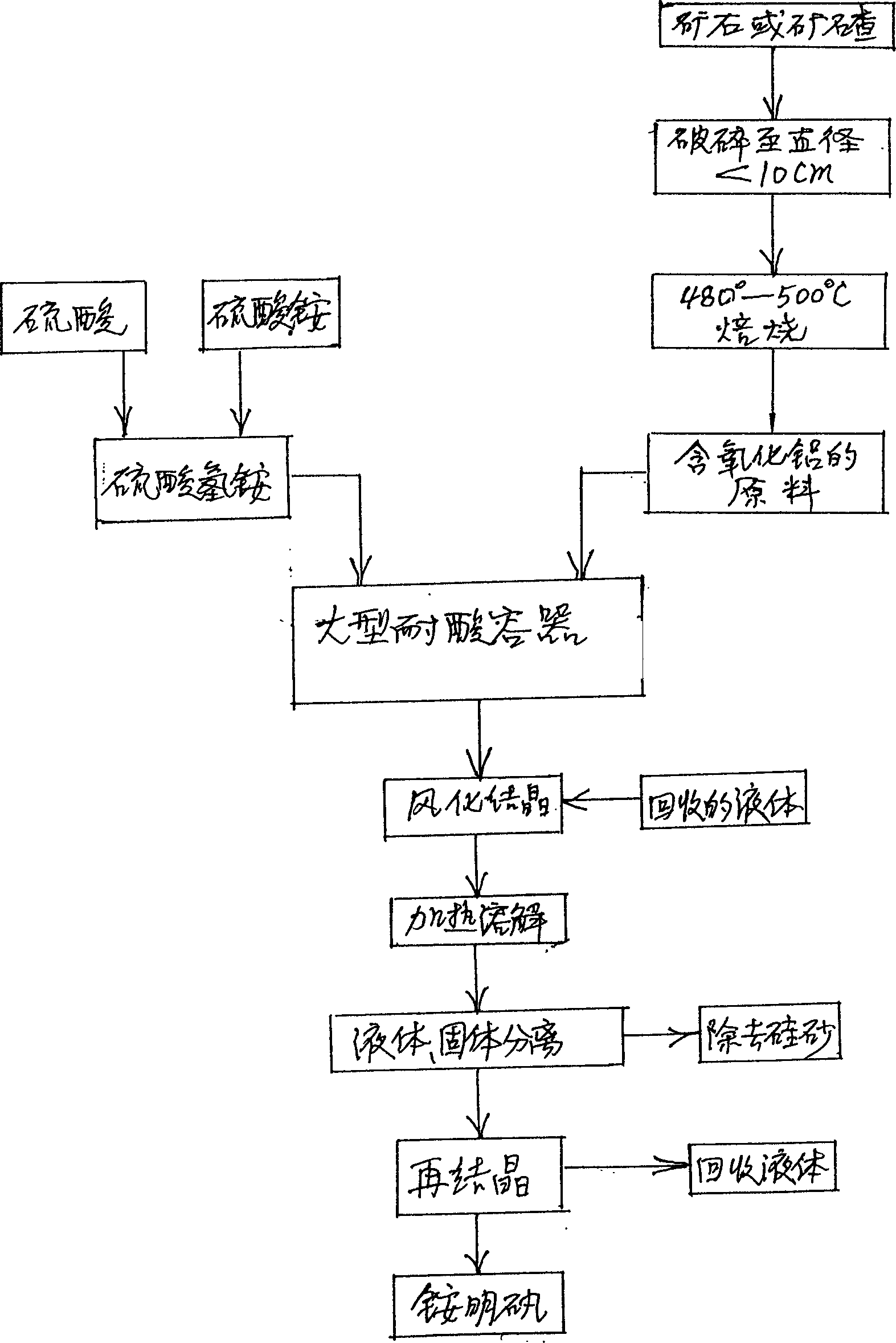

Embodiment 3

[0025] Take 15 tons of ammonium alunite slag with an alumina content of 10%, put it into a large acid-resistant container, add 2.04 tons of 90% sulfuric acid; put the obtained ammonium bisulfate together with excess sulfuric acid into a large acid-resistant container, add 2.55 tons of 90% sulfuric acid % sulfuric acid, after fully reacting to form ammonium aluminum sulfate, add appropriate amount of water to weathering at normal temperature, feed steam, be heated to 80 ℃ and make it dissolve, following steps are identical with embodiment 1, obtain crystalline ammonium alum product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com