Thinfilm for vacuum adsorped chip

A vacuum adsorption, thin film technology, applied in the preparation of test samples, lighting and heating equipment, furnace components, etc., can solve the problems of wafer contamination, wafer damage, manufacturing process errors, etc., to improve the wafer pass rate, Improve time and manpower effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

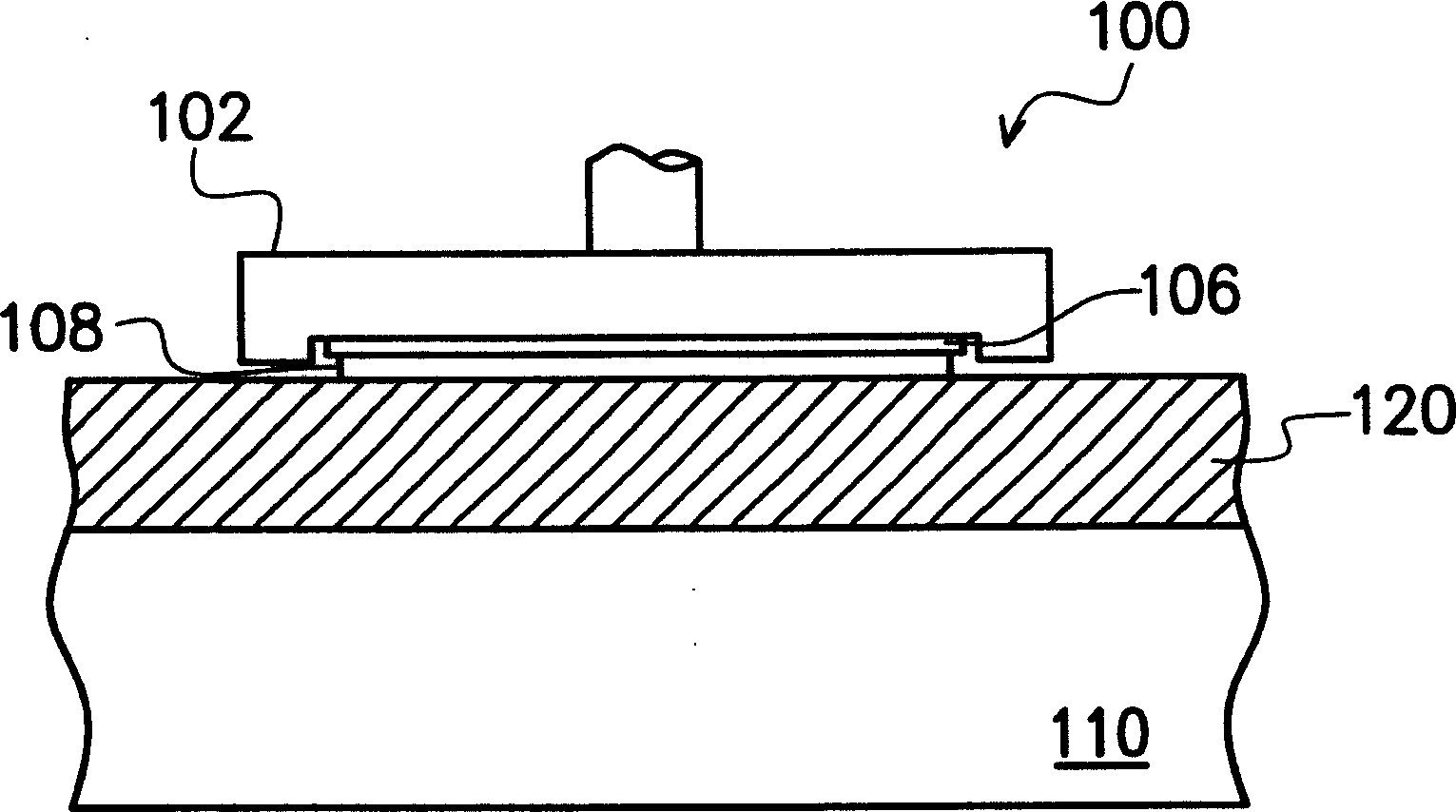

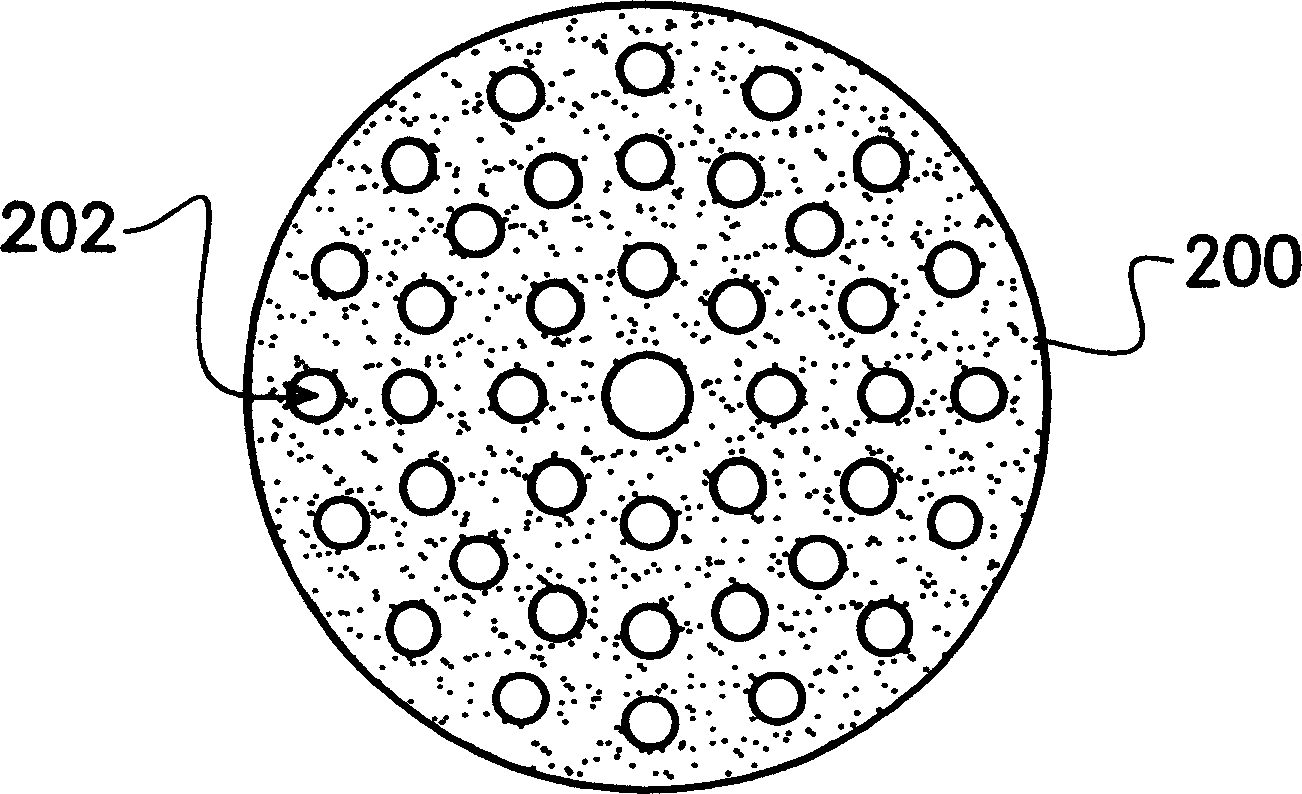

[0036] The membrane for vacuum adsorption wafer (Membrane) provided by the present invention can be applied in chemical mechanical polishing (Chemical Mechanical Polishing) device, as a membrane covering a porous plate in a vacuum adsorption polishing head (Polishing Head). However, the present invention can also be applied to other devices for vacuum suction (Suction), transfer (Transfer) and holding (Holding) wafers, and is not limited to this embodiment.

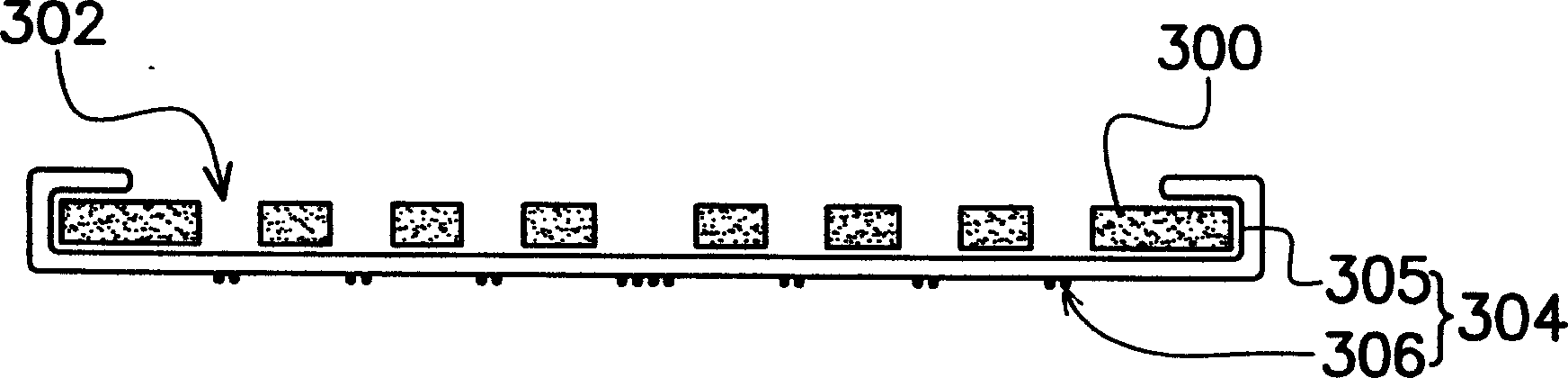

[0037] The chemical mechanical polishing device described in this embodiment generally includes a polishing head and a polishing table. Wherein, the grinding head is externally connected to a vacuum system, and also includes a chuck for fixing the wafer, and for the device in the chuck, please refer to the description of the preferred embodiment of the present invention. Figure 3A , Figure 3B and Figure 4 .

[0038] Figure 3A It is a schematic cross-sectional view of a porous plate for absorbing wafers and a film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com