Continuous automatic feed proportioning machine and its application

A technology of automatic batching and stepping motors, which is applied in the direction of special scales, conveyor objects, measuring devices, etc., to achieve the effects of improving operational reliability, accurate proportioning, and uniformity of equipment mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

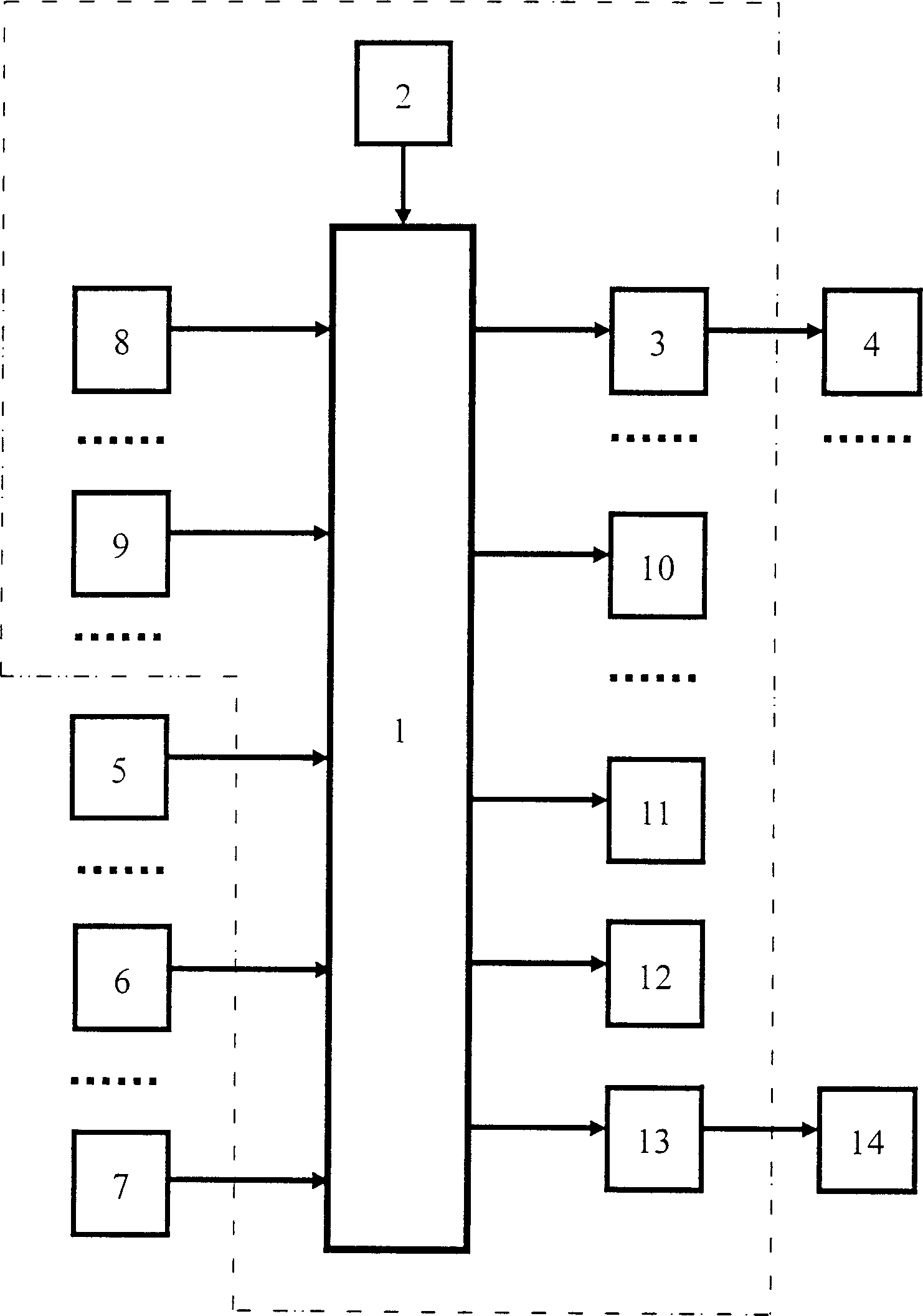

[0042] Batching device II is a two-group batching scheme to produce polyester POY colored fibers.

[0043]Step 1: SIEMENS S7-224 is selected for programming controller 1, SIEMENS TD200 text display is selected for man-machine dialogue interface 2, domestic SH-2H-130M type is selected for stepping motor drive device 3, domestic 130BYG-405A type is selected for stepping motor 4, Stalled-rotor alarm sensor 5 uses OMRON E2K type, batching bin material level sensor 6 and mixing bin material level sensor 7 use German Turck B12-M12-AN6X type, frequency converter 13 uses Fuji G11-0.75KW type, and AC motor 14 Choose the domestic 0.55KW type, according to the function of each device and according to the attached Figure 1 The connection relationship shown is assembled, and the control device 1 can be realized through software and hardware debugging.

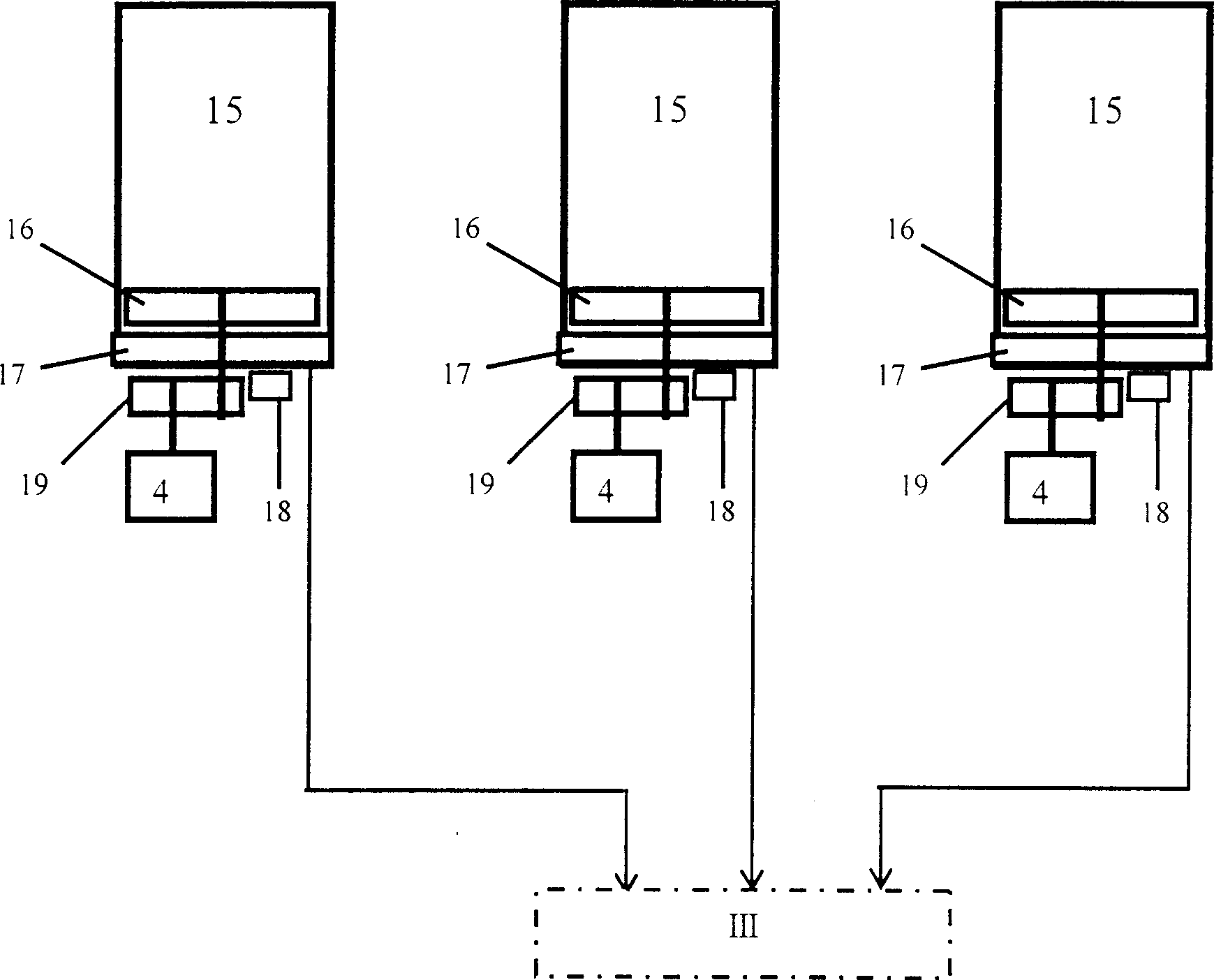

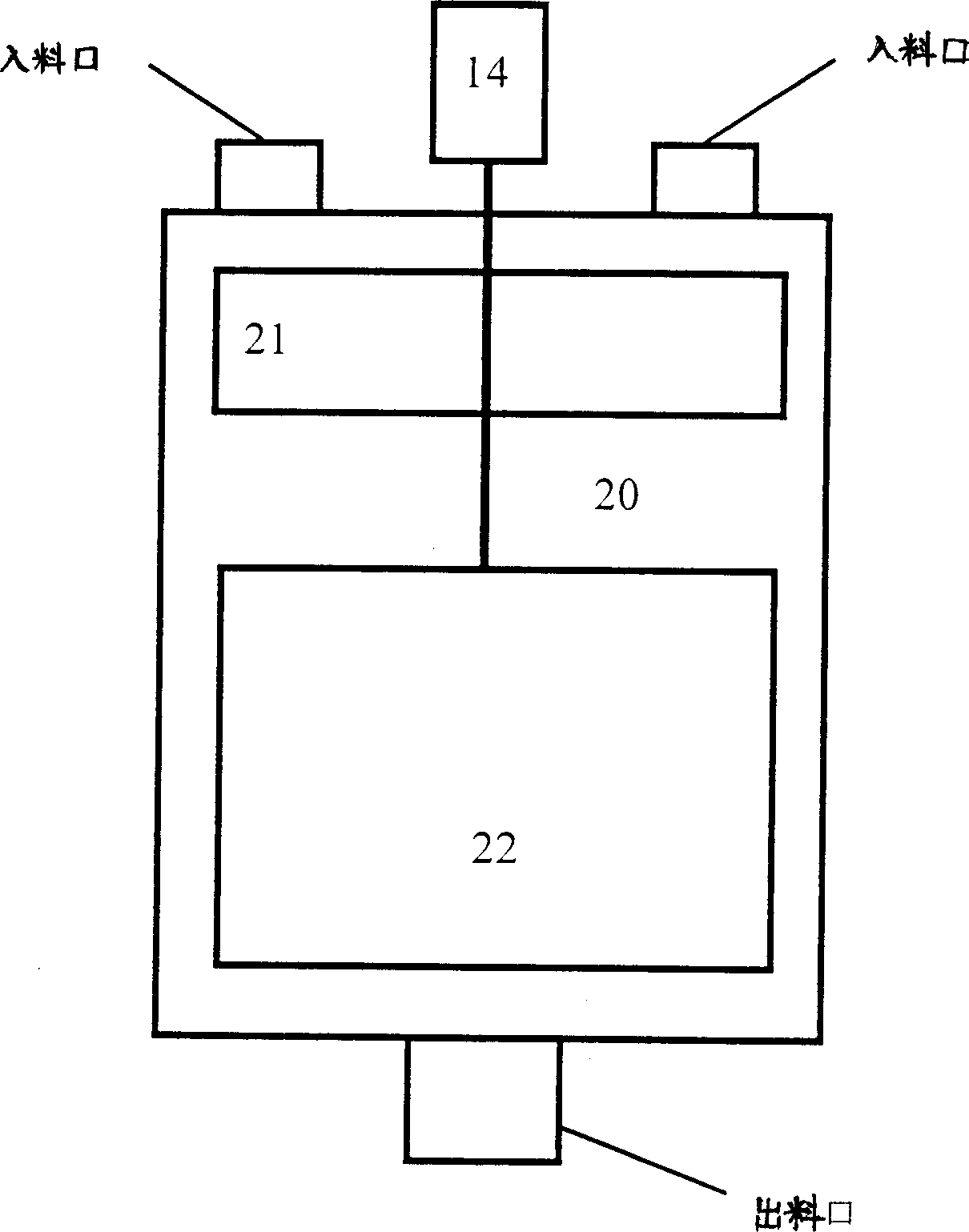

[0044] Step 2: Put batching device II and mixing device III according to the attached Figure II , three After assembling and debuggi...

Embodiment approach 2

[0049] Embodiment 2: The batching device II is a three-group batching scheme to produce nylon FDY colored deodorizing and antibacterial fibers. In this embodiment, unit 1 of the batching device II is loaded with nylon chips (base material), unit 2 is loaded with color masterbatch, and unit 3 is loaded with deodorizing and antibacterial masterbatch. According to the process proportioning ingredients.

Embodiment approach 3

[0050] Embodiment 3: The batching device II is a three-group batching scheme, which is used to produce nylon 6 toughened and colored engineering plastic parts by injection molding. In this embodiment, unit 1 of the batching device II is loaded with nylon 6 chips (base material), unit 2 is loaded with toughening masterbatch, and unit 3 is loaded with color masterbatch. According to the process proportioning ingredients.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com