Protective ring for bunch

A beamline and axis technology, applied in the field of "single moving retaining ring, can solve the problems of deformation of the funnel-shaped part, damage to the seal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

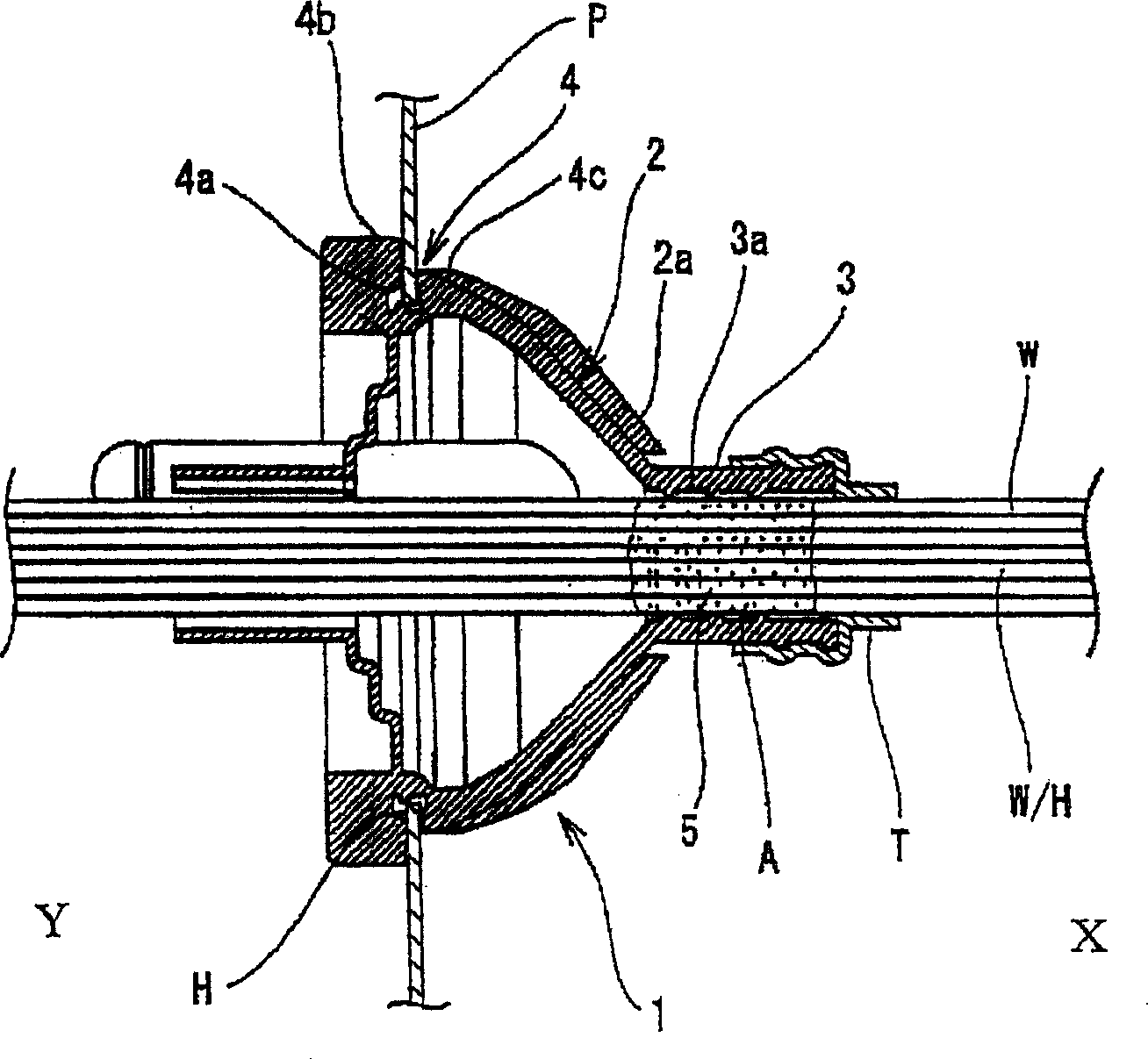

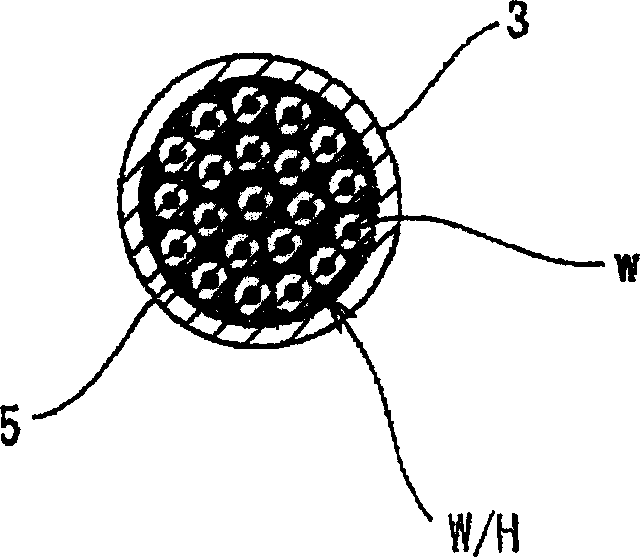

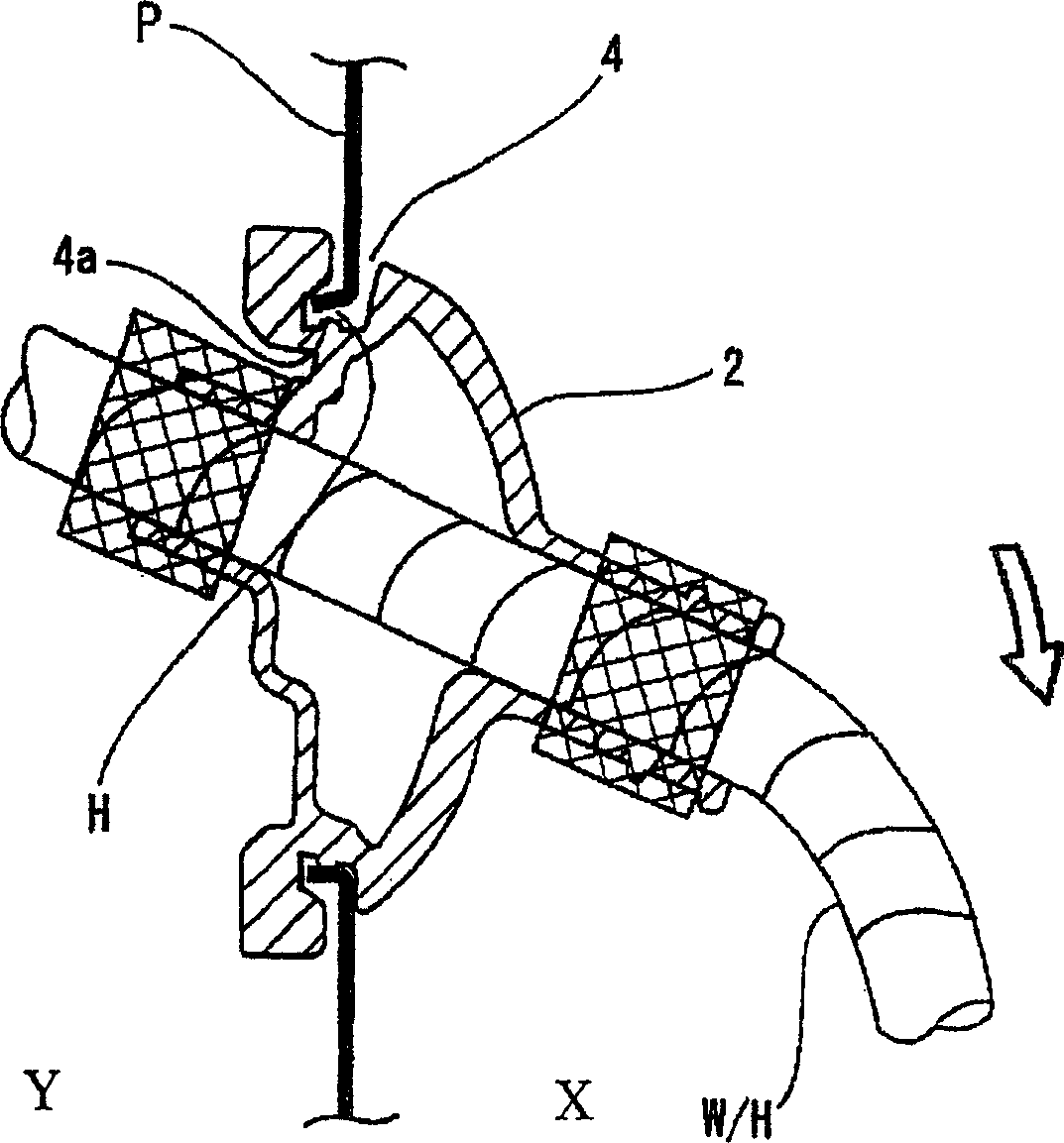

[0107] Such as figure 2 and Figure 3A As shown, the grommet 10 according to a preferred embodiment of the present invention is manufactured in a single piece and is made of rubber or elastomer. The grommet 10 includes a funnel-shaped portion 12 having a conical surface with: an open end (end of larger diameter); a narrow end; a first tubular portion 11, Extending outwardly from said narrow end; a closed surface 20 at said flared end. The closure surface 20 is thin and has a communication channel substantially aligned with the diameter of the closure surface. A second tubular portion 21 protrudes from a wire receiving hole provided at the central portion of the communication channel. An outer annular groove 16 is provided near the flared end of said funnel-shaped portion 12 .

[0108]On the conical outer surface of the funnel-shaped portion 12, a plurality of funnel ribs 13 are provided. These funnel ribs 13 radiate in all directions from the narrow end on the conical ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com