Cold synthesizing method for obtaining bar-like semifinished product frow which to produce high-performance super conducting cables

A technology for semi-finished products and cables, which is applied in the field of cold synthesis for obtaining rod-shaped semi-finished products for manufacturing high-performance superconducting cables, and can solve problems such as low critical current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

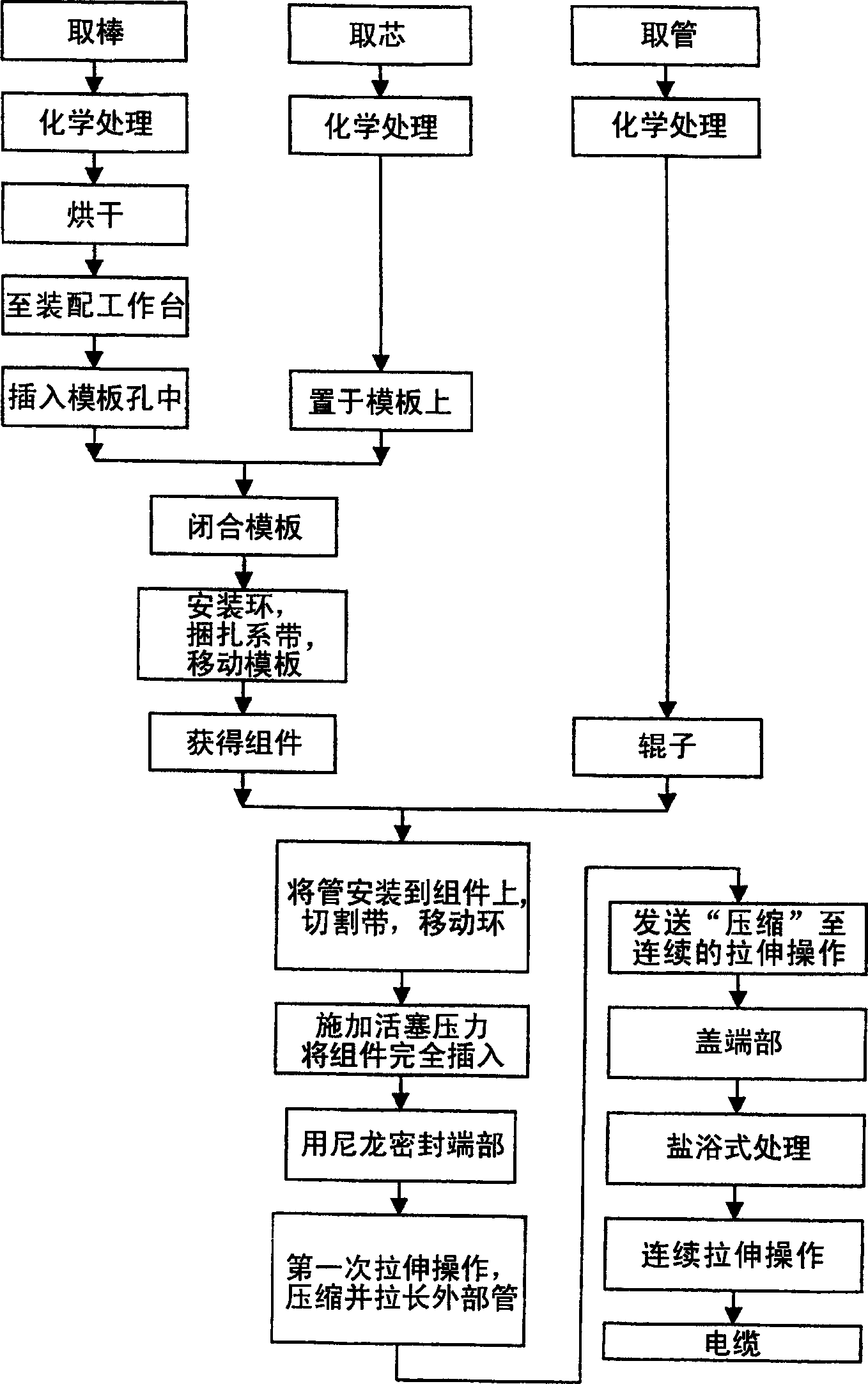

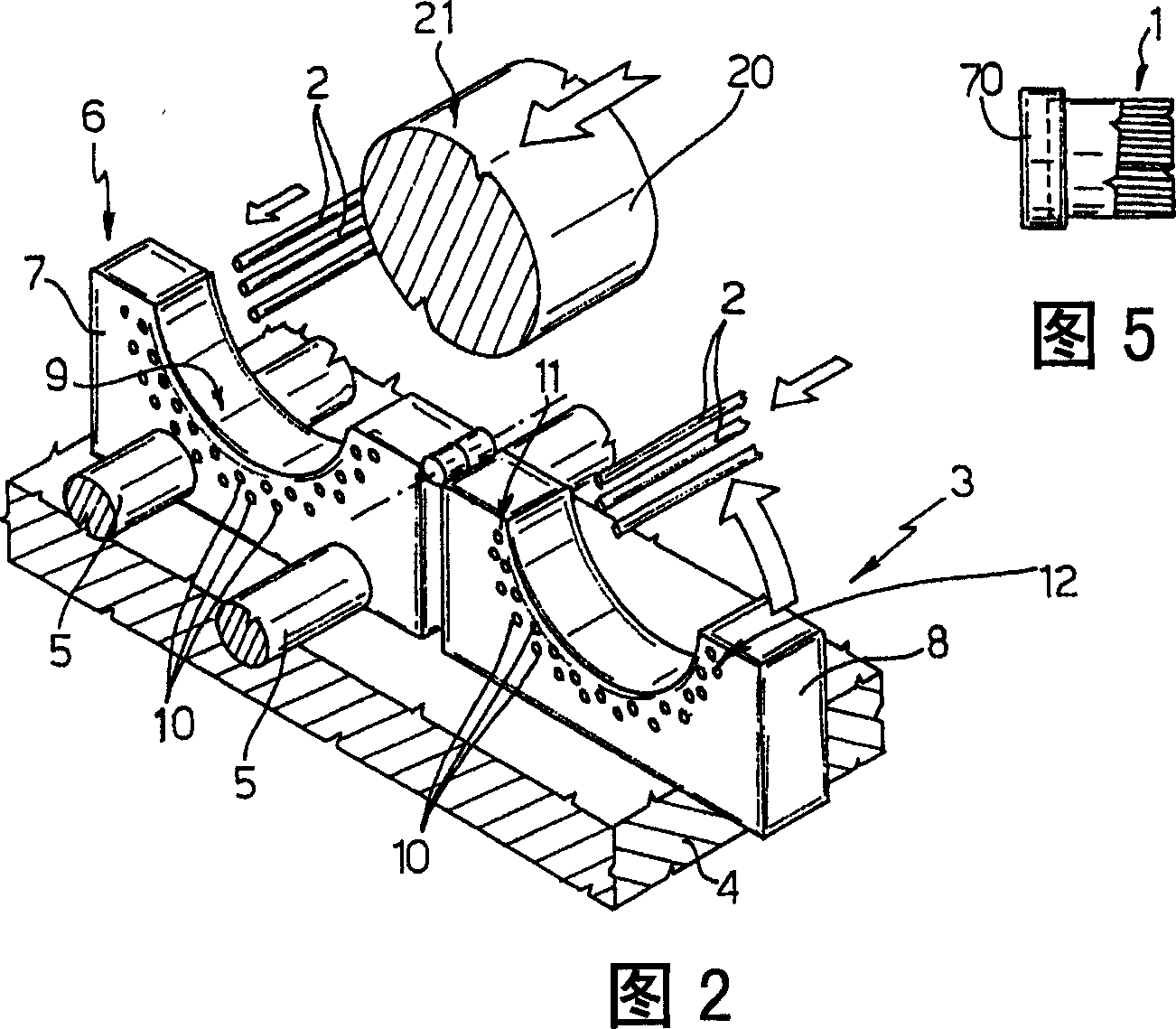

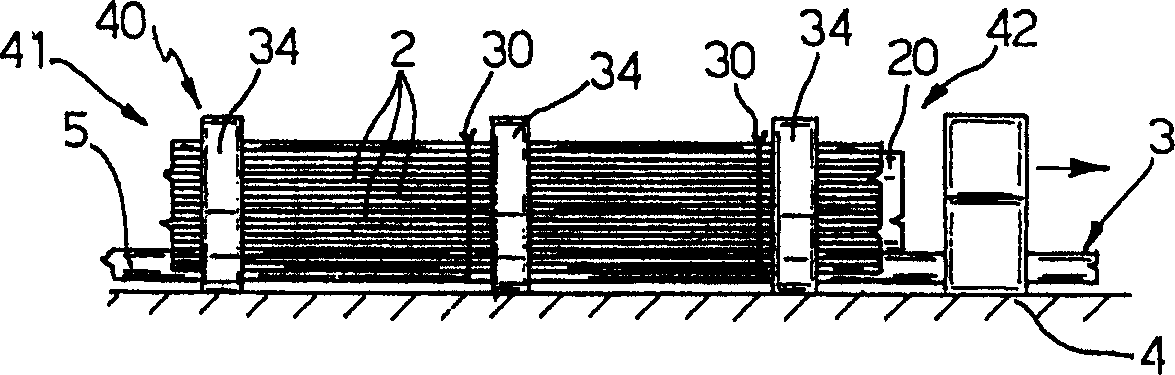

[0019] With reference to the accompanying drawings, numeral 1 (Fig. 5) represents the whole of the rod-shaped semi-finished product manufactured by the cold synthesis method according to one aspect of the present invention, and this semi-finished product can be used among the method for manufacturing superconductor cable, according to another aspect of the present invention, its Characterized by the fact that any one plastic deformation step is completely e.g. cold deformation at ambient temperature, as in the process figure 1 shown.

[0020] The invention begins with rods 2 manufactured by known methods, each rod comprising a core defined by monofilaments and multifilaments of superconductor material, in particular NbTi alloy, and a copper sheath, possibly with a superconductor interposed between copper and Barrier layers made of precious metals or metal alloys. In the case of a multi-filament rod, the core consists of 121 individual filaments made of a superconducting alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com