Animal protein fiber and preparing method thereof

A protein fiber and protein technology, applied in the field of animal protein fiber, can solve the problems of poor processing performance and high production cost, and achieve the effects of improving the curling and fluffy, increasing the probability and increasing the fiber curling and fluffy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

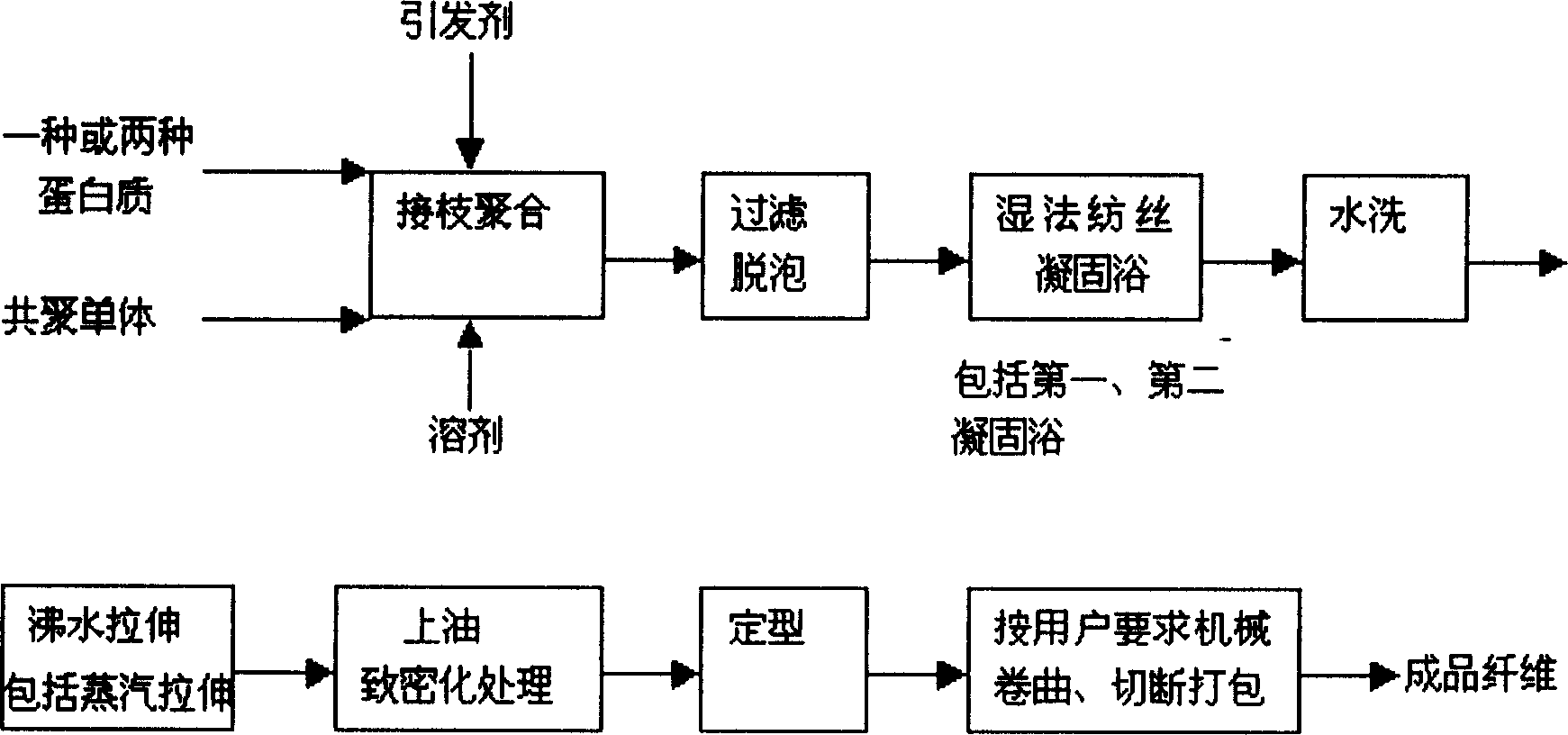

Method used

Image

Examples

Embodiment 1

[0037] In a 10-liter reactor, add 0.70 kg of 80-mesh casein powder and 0.20 kg of gelatin powder into 14.5 kg of 63.5% zinc chloride aqueous solution in equal amounts for 20 times, and stir while adding. The temperature was kept below 15°C and stirred for 10 hours. After 1 hour the temperature was raised to 73°C. Add 1.20 kg of acrylonitrile containing 0.0088 kg of azobisisobutyronitrile in equal amounts ten times within 40 minutes, and keep stirring at this temperature range for 6 hours. The viscous slurry prepared in this way is removed unreacted acrylonitrile under a vacuum degree of 100 Pa, and a 400-mesh sieve is used as a filter medium to filter out impurities, and vacuum defoaming for subsequent use.

[0038] The falling ball viscosity of this slurry is 220 seconds * , The content of water coagulable solids is 9.70%, which is suitable for spinning.

[0039] * The time required for a steel ball with a diameter of 3mm (0.110±0.001g) to settle 254mm in a glass tube wit...

Embodiment 2

[0041] The spinning dope was formulated as described in Example 1. The slurry uses 63.5% zinc chloride aqueous solution as a solvent, contains 6.3% of modified protein, of which keratin protein accounts for 73.6%, and casein protein accounts for 26.4%. Acrylonitrile monomers are grafted and copolymerized to prepare spinning slurry. After the slurry is filtered and defoamed, it is wet-spun with a spinneret with 2000 holes and a micropore diameter of 0.08mm, solidified in a coagulation bath containing 22% zinc chloride aqueous solution at 10°C, washed with warm water at 40°C, and stretched 2.8 times , and then stretched 8 times in a boiling water bath. After oiling, the tow is relaxed and densified in hot air at 105°C, and then relaxed and shaped in steam for 5 minutes to make fibers. The fiber fineness is 1.75dtex, the tensile strength is 1.5cN / dtex, and the elongation at break is 25.1%. Can be spun and weaved.

Embodiment 3

[0043] The spinning slurry was prepared as described in Example 1, and the slurry contained 86.8% of keratin and 13.2% of gelatin among the modified proteins. With acrylonitrile graft copolymerization, the slurry is made into fibers by the spinning method described in Example 2. The fiber fineness is 1.65dtex, the tensile strength is 2.0cN / dtex, and the elongation at break is 22.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com