Paper feeder and a printer employing the same

A technology for printing paper and feeding paper, which can be used in printing devices, instruments, printing and other directions, and can solve problems such as bulky size, complex printer structure, and increased manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

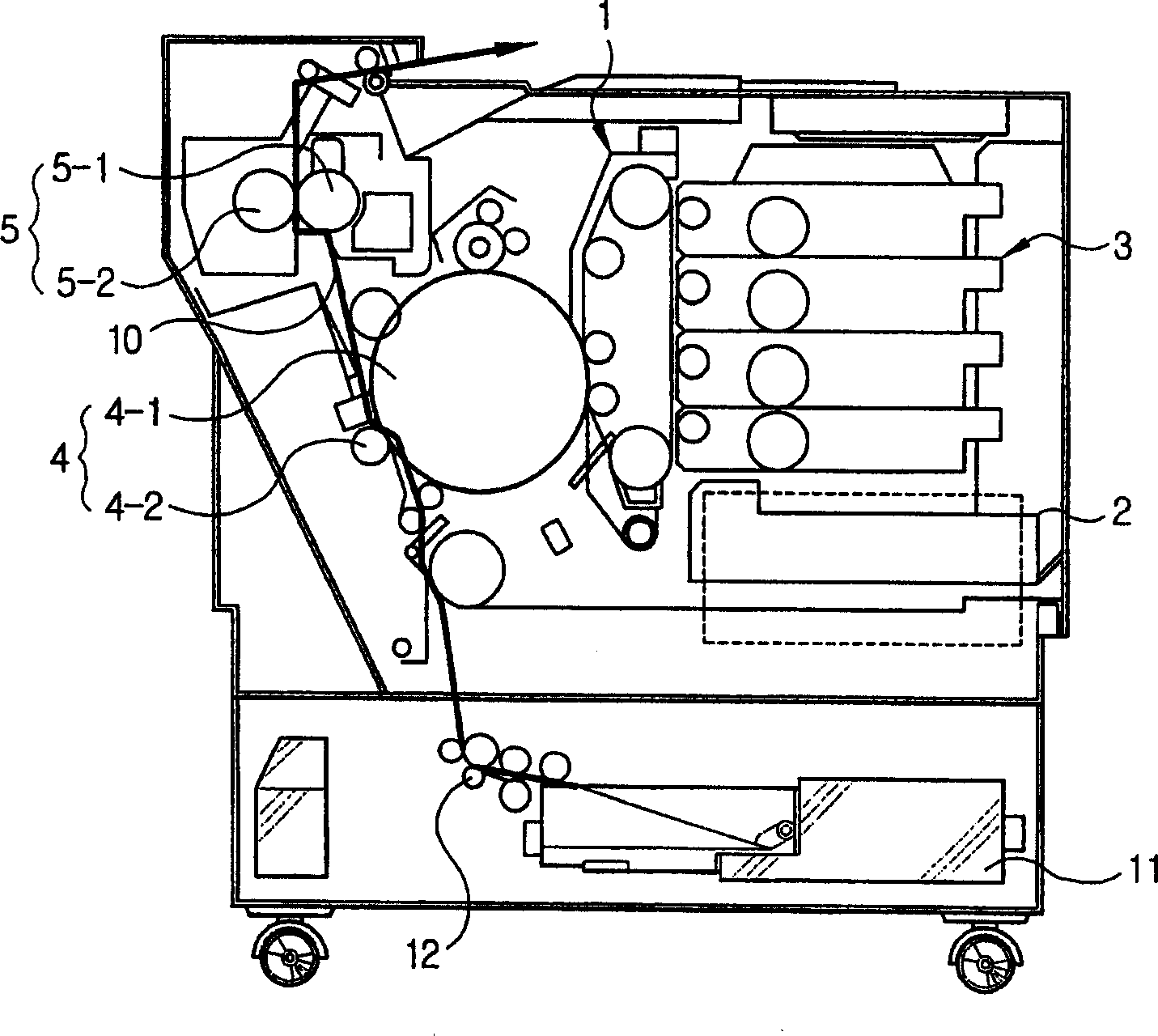

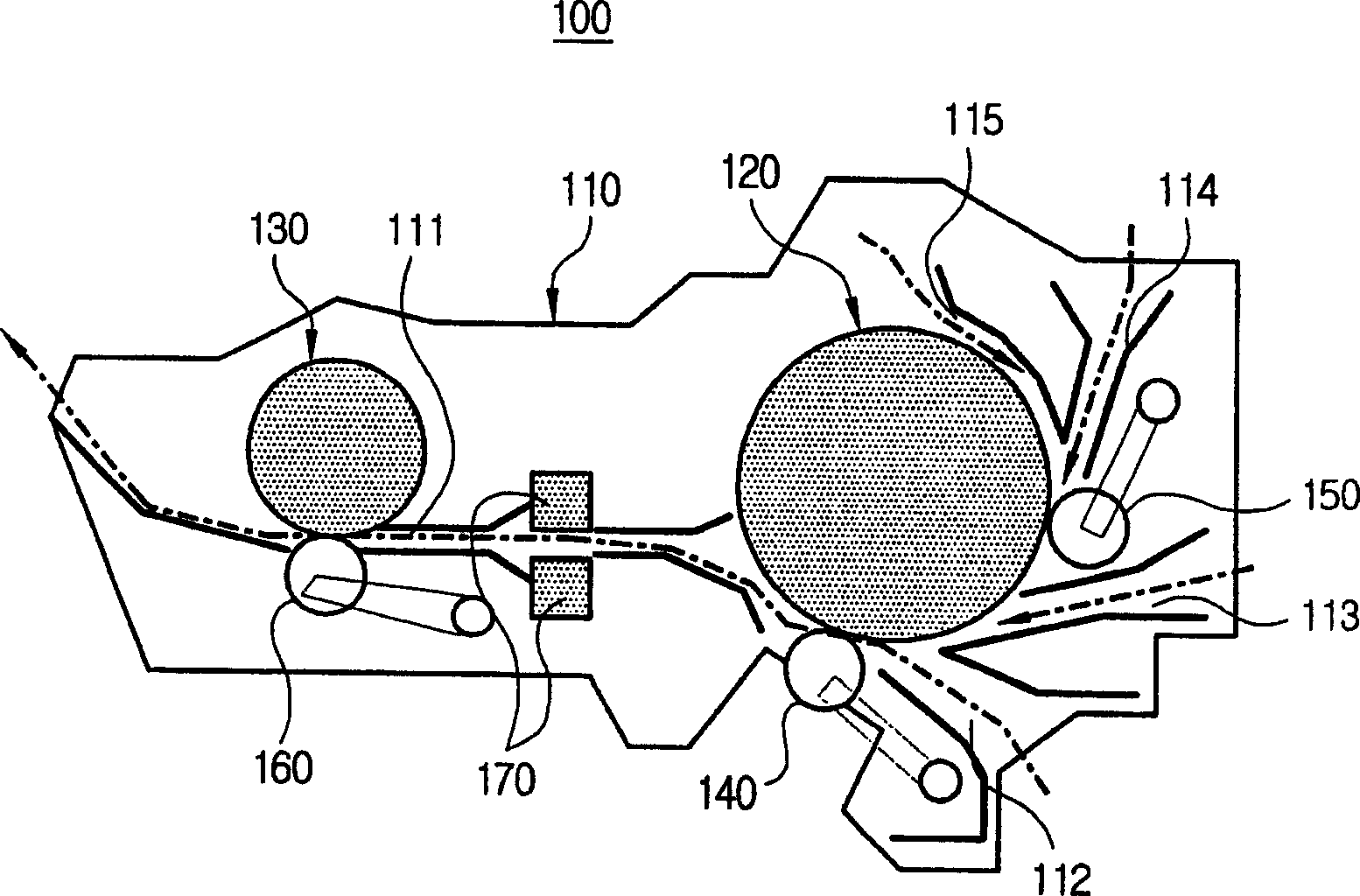

[0026] refer to figure 2 and image 3 , The paper feeder 100 of the printer according to the preferred embodiment of the present invention is arranged between one end of the main conveying channel 10 and the paper feeding unit. The main delivery channel 10 is located in the printer body and passes through the transfer unit 7 and the melting unit 5 . The paper feeding unit includes a paper feeding cassette 11 for an automatic paper feeding mode, a manual paper feeding tray 21 for a manual paper feeding mode, and dual printing channels for duplex printing. Here, a paper feeding cassette is detachably installed on the printer for storing a plurality of sheets, and a double printing path is used for returning printing paper printed on one side in duplex printing (dual printing). No matter whether it is placed in the paper feeding box 11 or the manual feeding tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com