Shaft type speed variator with planetary gear transmission

A technology of planetary gears and transmissions, used in gear transmissions, transmissions, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

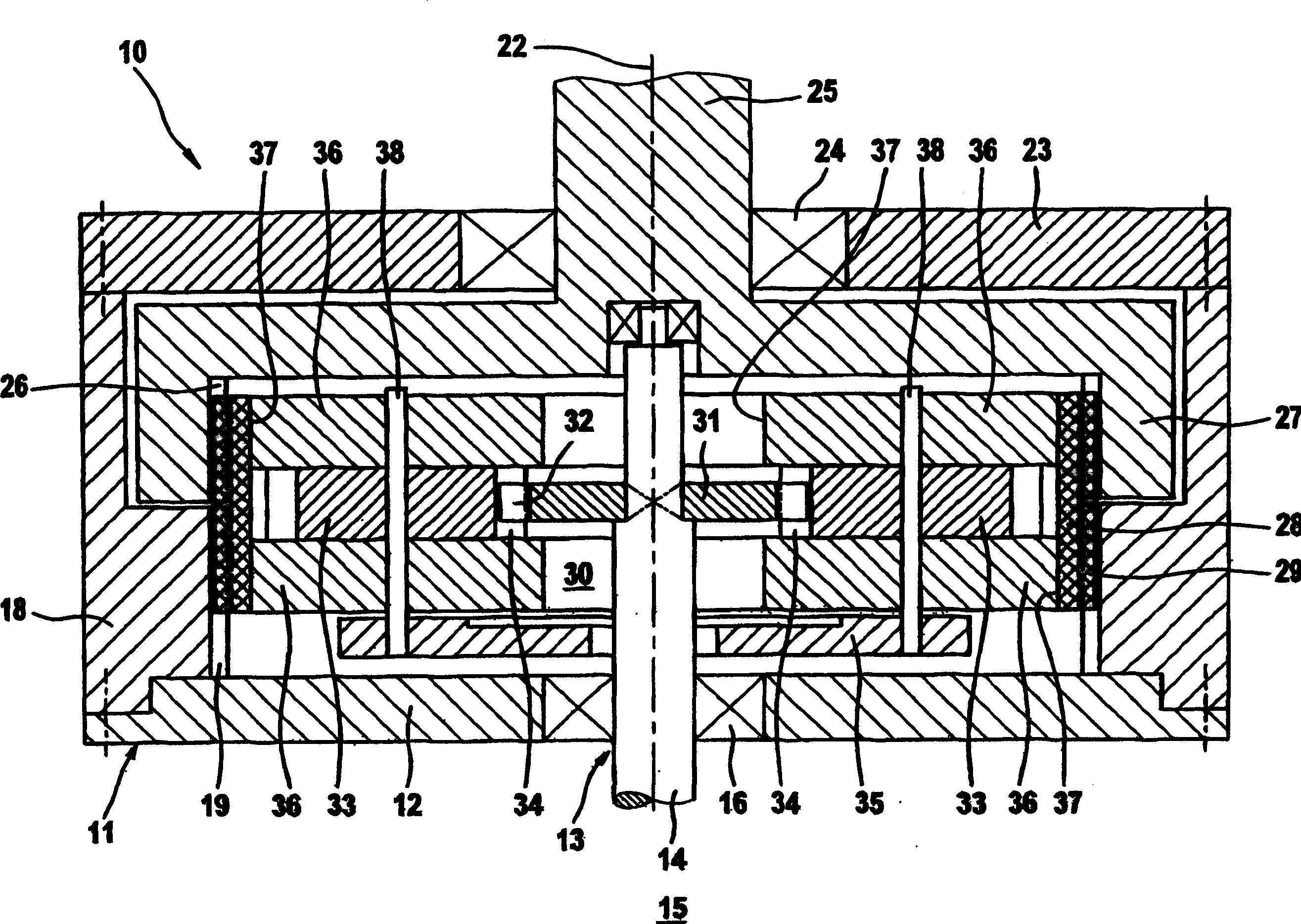

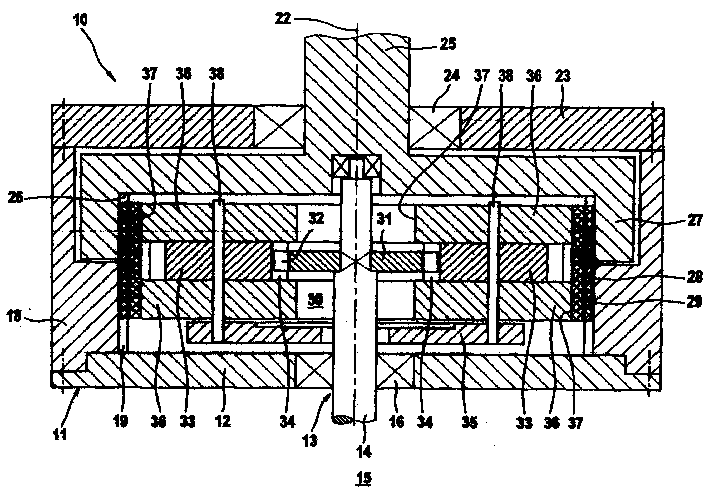

[0012] The axial transmission 10 designed according to the invention, which can be completely injection-molded from plastic, is shown in a schematic axial profile in the drawing and has a housing 11 with an approximately disc-shaped base plate 12 . A central through-hole 13 is used to insert the drive shaft 14 , which can directly be the main shaft of the drive motor 15 . The diameter of the bore 13 is greater than the diameter of the shaft 14 , so that there is no radial bearing function here, since this function is assumed by the motor bearing 1 . Otherwise, or when the base plate 12 is the bearing cover of the motor 15 , the hole 13 is equipped with a bearing 16 . In contrast, the drive shaft 14 is mounted, as shown in the sketch, in a bearing-mounted output shaft 25 in order to avoid bending stresses.

[0013] In the illustrated embodiment, the base plate 12 has a profiled design at its edge in order to positively accommodate a support ring 18 fixed to the housing, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com