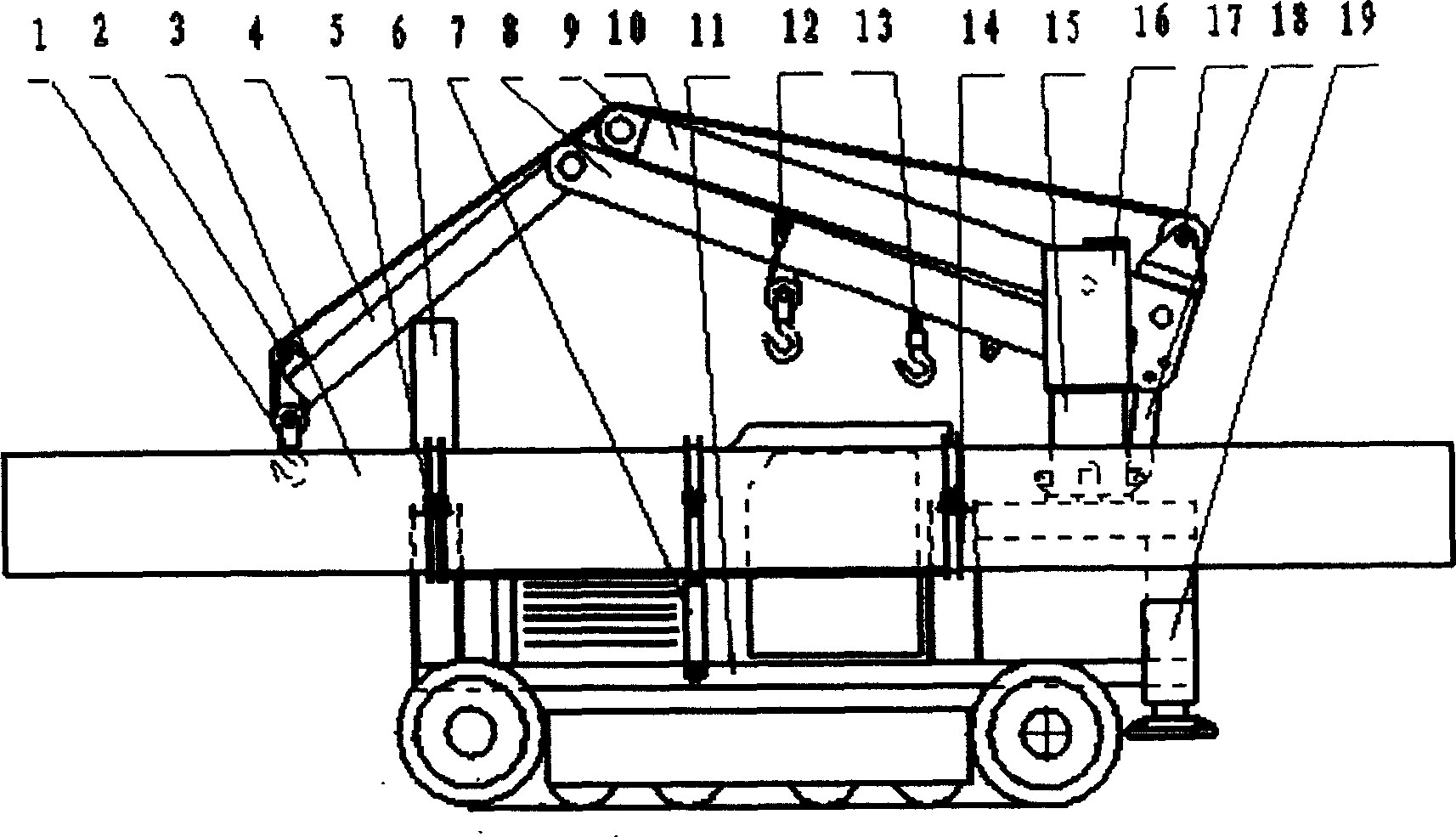

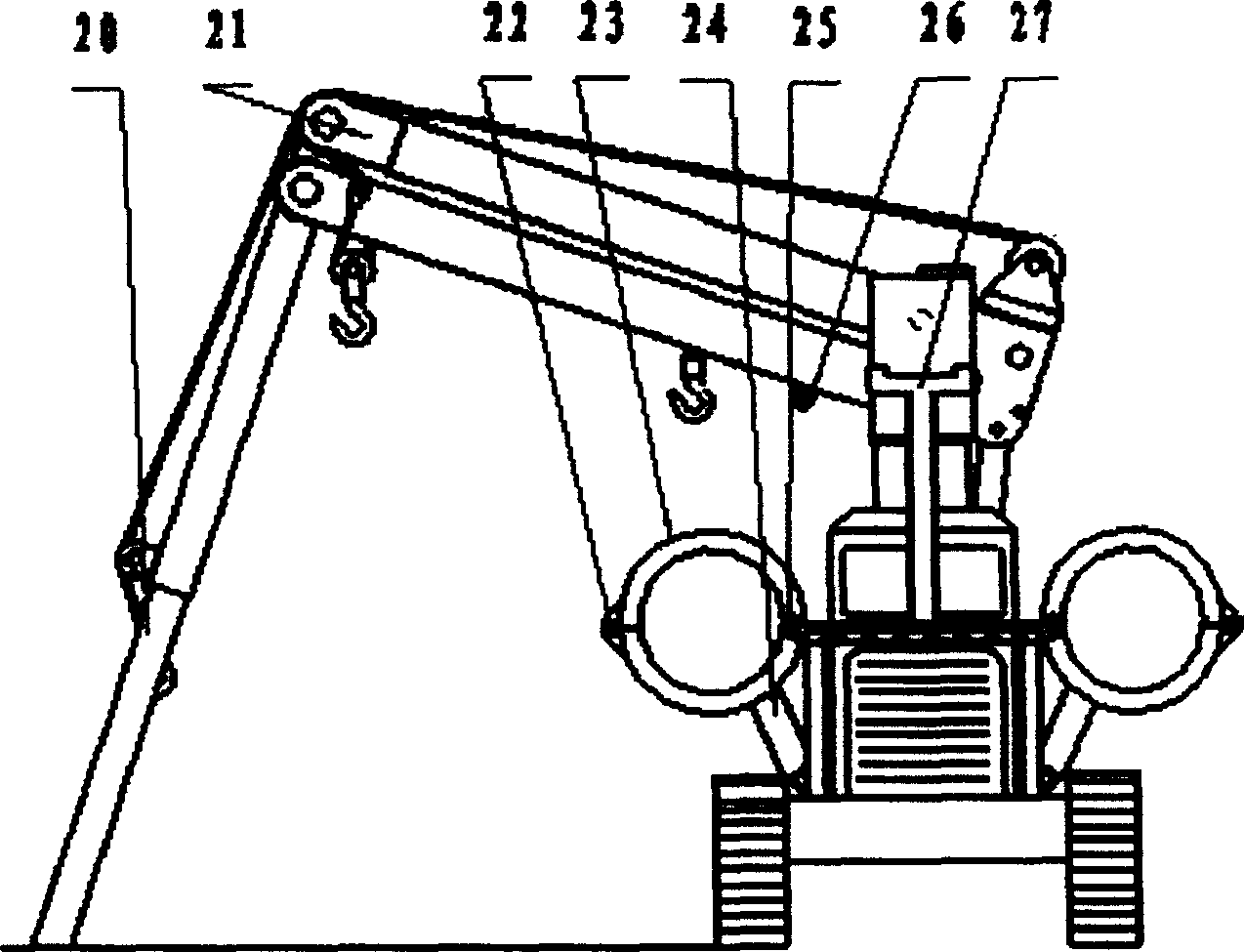

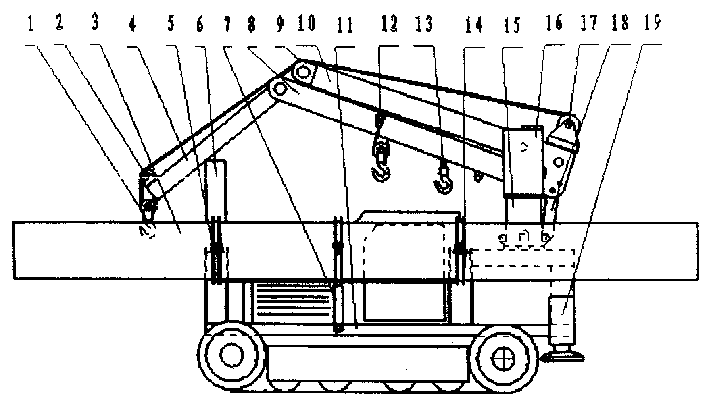

Pipe suspension transferring machine

A pipe and boom technology, applied in the field of pipe hoists, can solve the problems of increasing equipment supporting funds and fuel consumption, increasing construction equipment supporting funds, auxiliary construction time and pipeline construction period, and high risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The crawler bulldozer and wheel loader are used as the carrier body, and the front end, middle rear end and rear end of both sides of the chassis girder are properly reinforced, and the rear end of the girder is appropriately lengthened and reinforced with the same section steel as the girder. The bolt connection method is used to install steel pillars with channel-shaped cross-sections on the front, middle, and rear ends of both sides of the girder. The upper ends of the two pillars at the front end are connected by steel with a channel-shaped section, and connected to the girder by reinforcing plates and bolts. The upper and lower ends of the middle rear end and rear end pillars are connected to form a reinforced platform with steel with a channel steel section, and are connected to the girder with reinforcing plates and bolts. The middle end of the girder installs the hinge support of the lifting hydraulic cylinder with bolts, the rear end of the girder reinforces th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com