Circuit marking method for medical ambi-plasma cutting head

A technology of plasma and cutting head, which is applied in the field of circuit identification of plasma cutting head, can solve the problems of capacitor breakdown, poor electric pulse impact ability, unreliable power source measurement identification value, etc., and achieve strong electric pulse impact ability, The effect of reliable measurement identification value and accurate and reliable measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

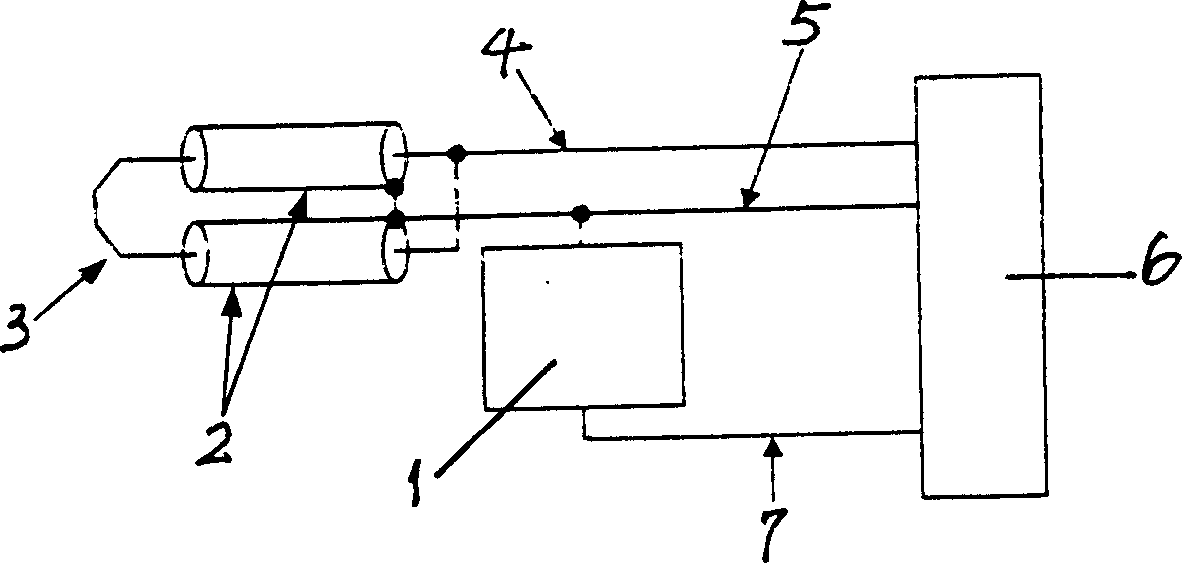

[0023] Example 1, such as figure 2 An example of using a Zener diode as a two-port voltage regulator is given. The anode of the Zener diode is connected to the cut outer electrode. During online measurement, when the power source flows positive current into the negative pole of the Zener diode, measure its steady voltage value, and after quantification, the model code of the cutting head can be determined. When the power source flows negative current into the negative pole of the Zener diode, the measured voltage value is the forward voltage drop value of the diode.

Embodiment 2

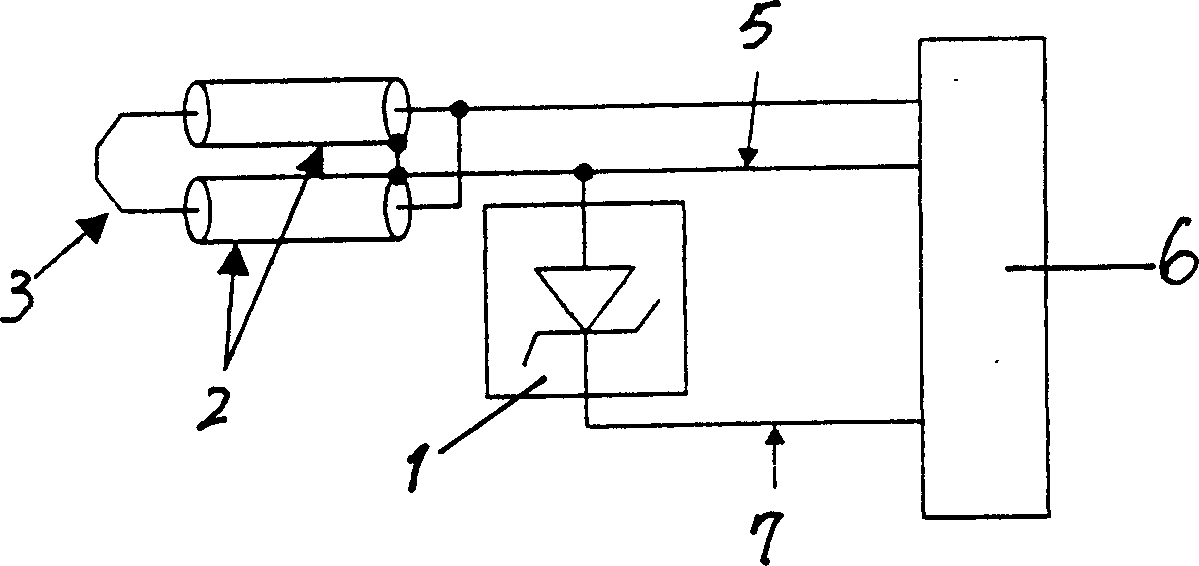

[0024] Example 2, such as image 3 Gives another example of using a Zener diode as a two-port voltage regulator, and the negative pole of the Zener diode is connected to the cutting external electrode. During online measurement, when the power source flows negative current into the positive pole of the Zener diode, measure its voltage stabilization value, and after quantification, the model code of the cutting head can be determined. When the power source flows positive current into the negative pole of the Zener diode, the measured voltage value is the forward voltage drop value of the diode.

Embodiment 3

[0025] Example 3 as Figure 4 An example of using two Zener diodes in reverse series as a two-port voltage stabilizer, the negative poles of the two Zener diodes are connected together, and the positive pole of one Zener diode is connected with the cutting external electrode is given. During online measurement, when the power source flows positive current into the marked electrode, measure the D1 steady voltage value plus the forward voltage drop of D2; when the power source flows negative current into the marked electrode 8, measure the D2 steady voltage value plus D1’s positive pressure drop. According to the measured two sets of voltage values, the model code can be determined after quantification. Since there are two sets of voltage values, more coding combinations can be formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com