Hydroxyalkyl benzophenone photocuring agent and its preparation and use

A technology of phenyl ketone and hydroxycyclohexyl, which is applied in the field of photocuring, can solve the problems of yellowing, peculiar smell, and it is difficult to meet the special requirements of photocuring initiators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

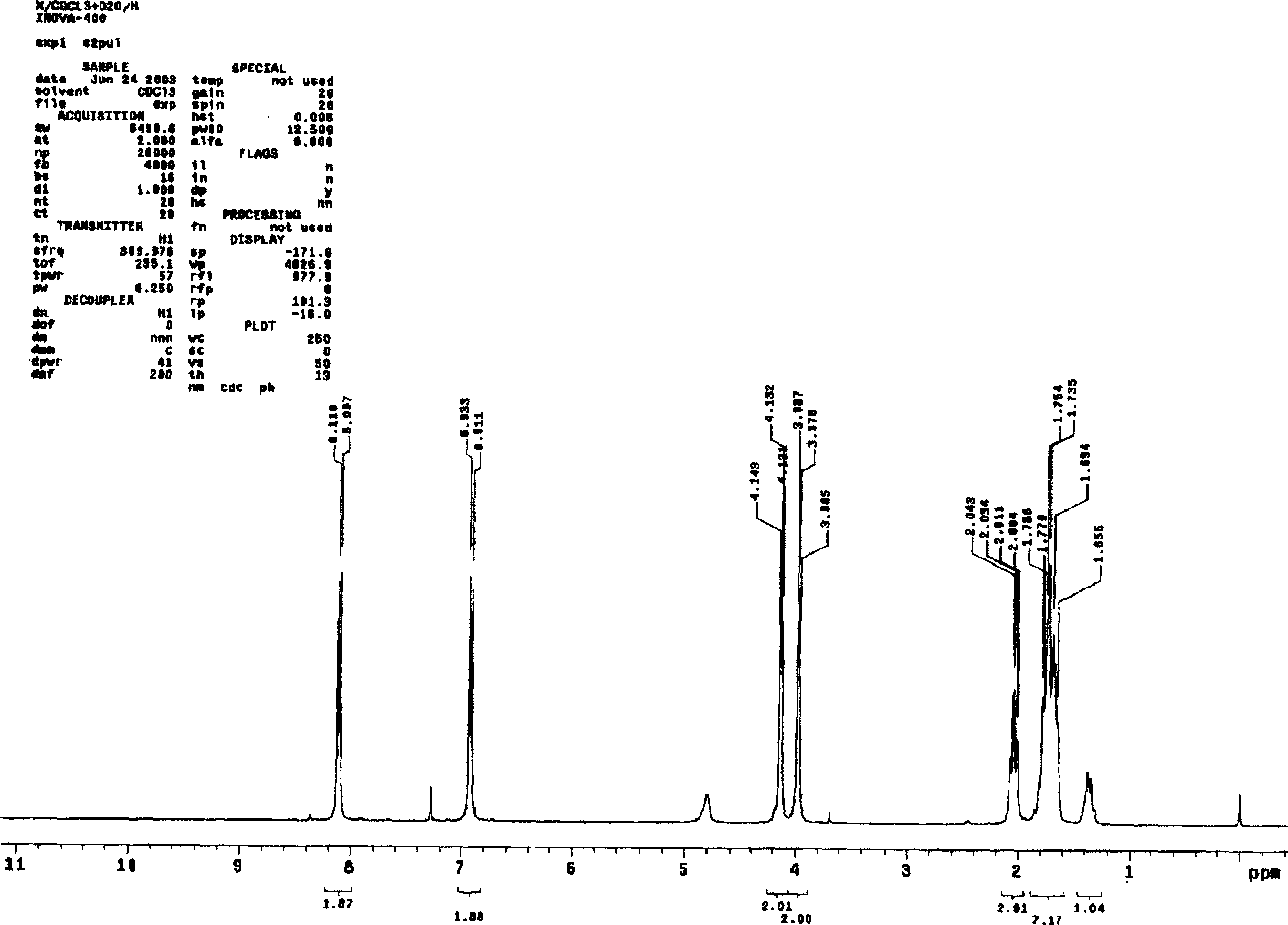

Image

Examples

Embodiment 1

[0041] Example 1 (1-hydroxycyclohexyl) [4-(2-hydroxyethoxy) phenyl] ketone synthesis

[0042] Preparation of step A1-cyclohexyl-4-(2-acetoxyethoxy) phenyl ketone

[0043] Under the ice-water bath, add 40ml of dichloromethane (or 1,2-dichloroethane) and 80.0g of aluminum trichloride to the 250ml reactor, and the system is fully cooled. Add 37.2g of cyclohexanoyl chloride dropwise into the funnel, control the rate of addition, and keep the reaction temperature at about -5-5°C. After the dropwise addition, continue to stir for about half an hour.

[0044] Add 44.8 g of 2-phenoxyethyl acetate dropwise into the reactor with a constant pressure funnel at a temperature of about -5-5° C., and continue stirring for 1 hour after the dropwise addition is completed.

[0045] Stop the reaction, pour the reactant into a mixed system of 350g ice and 150ml concentrated hydrochloric acid, stir vigorously, let it stand, and separate the layers to obtain the organic oil in the lower layer, whic...

Embodiment 2

[0061] Embodiment 2 (1-hydroxycyclohexyl) [4-(2-hydroxyethoxy) phenyl] ketone photocuring experiment A

[0062] 73 parts of acrylic modified epoxy resin, 20 parts of 1,6-hexanediol diacrylate, 3 parts of trimethylolpropane triacrylate, and 4 parts of (1-hydroxycyclohexyl)[4-(2- Hydroxyethoxy) phenyl] ketone is evenly mixed, coated on a 2×4cm clean glass sheet with a thickness of about 500μm, placed under a 500W high-pressure mercury lamp, exposed for 8-10 seconds, and the exposure distance is 10cm, coated The layer is fully cured.

Embodiment 3

[0063] Example 3 (1-hydroxycyclohexyl) [4-(2-hydroxyethoxy) phenyl] ketone photocuring experiment B

[0064] 60 parts 1,6-hexanediol diacrylate, 36 parts trimethylolpropane triacrylate, and 4 parts (1-hydroxycyclohexyl)[4-(2-hydroxyethoxy)phenyl]methanone Mix evenly, spread on a 1mm thick clean glass piece, and then cover with another 1mm thick clean glass piece. After being exposed to sunlight for 6-8 seconds, the two glass sheets are completely tightly bonded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com