Alpha-type hemihydrated gypsum producing process and apparatus thereof

A technology of hemihydrate gypsum and production process, applied in the field of building materials, can solve the problems of poor performance of α-type hemihydrate gypsum, unstable steam temperature and high safety requirements, and achieve stable heat supply, small temperature change and high heat utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described below by way of examples.

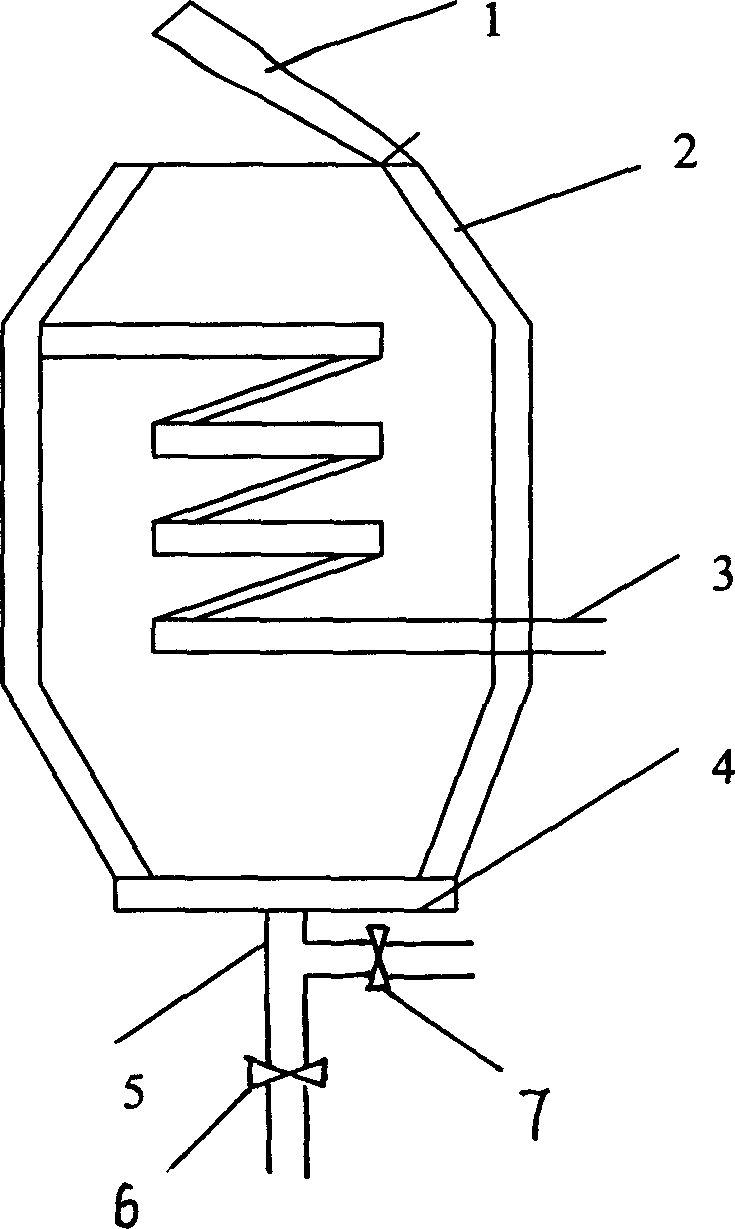

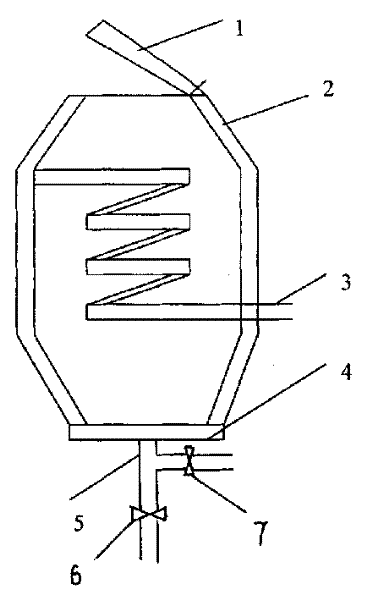

[0016] The diameter of the container 2 of design autoclave is 2m, and height is 2.5m, and interlayer spacing is 5cm, and the disk shape diameter of coil pipe 3 is 70cm, and the diameter of pipe is 6cm, and the diameter of loam cake 1 is 40cm, and the diameter of lower cover 4 The diameter of is 50cm, and corresponding drain pipe, drain control valve and exhaust control valve are set on the lower cover 4. The autoclave is made of steel plate. The interlayer of the container 1 and the coil pipe 3 communicate with the heat conduction oil furnace. During production, the gypsum ore is processed into fragments with a particle size of 1-5 cm, put into an autoclave, and water is added to submerge the gypsum ore. After the upper cover 1 is closed, the heat transfer oil heated by the heat transfer oil furnace is pumped into the spacer and the coil respectively. Raise the temperature in the container to abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com