Antiskid material sprinkling apparatus

A spraying device and anti-slip technology, which is applied in the field of anti-slip material spraying devices, can solve problems such as damage, inability to spray, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

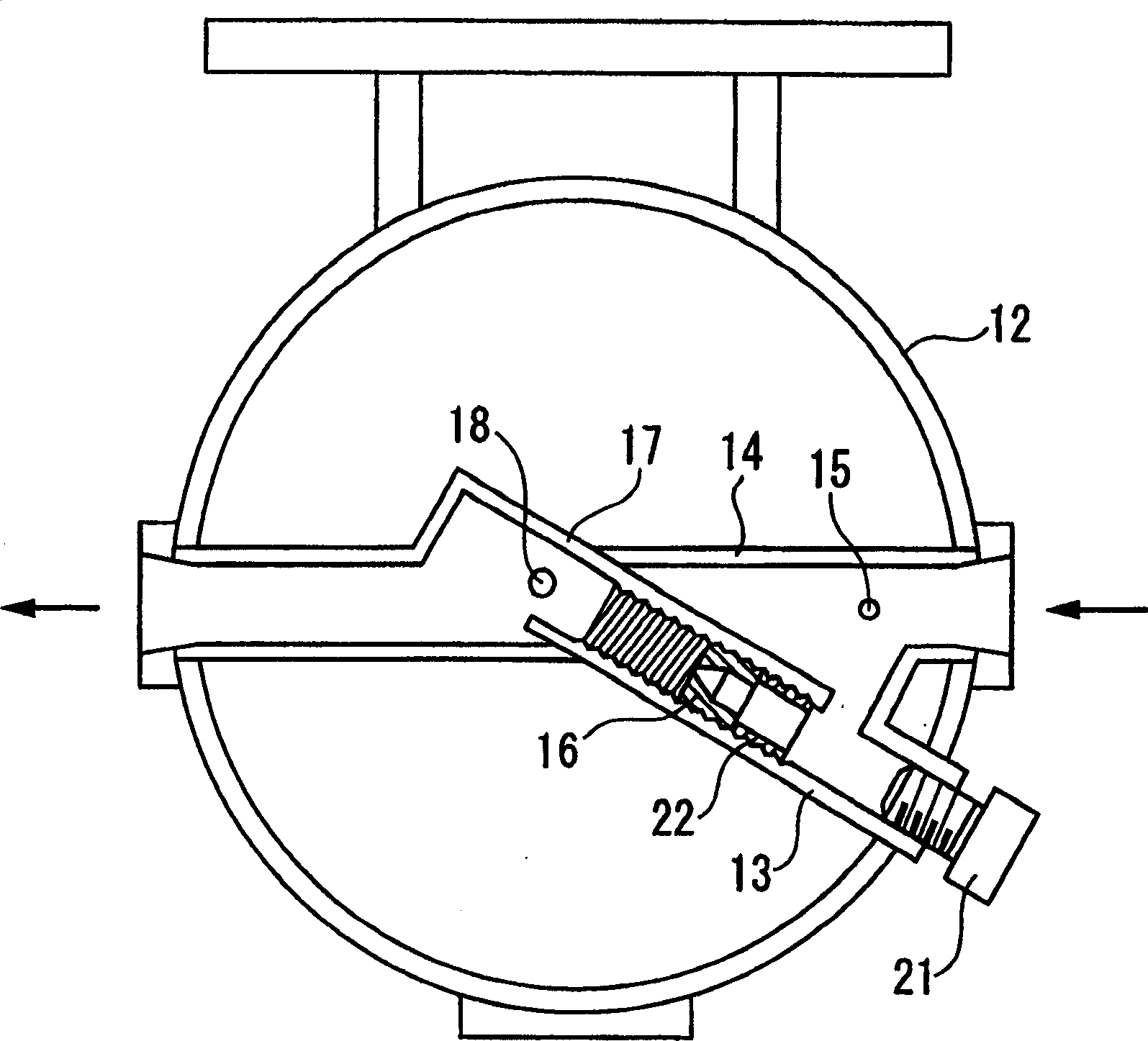

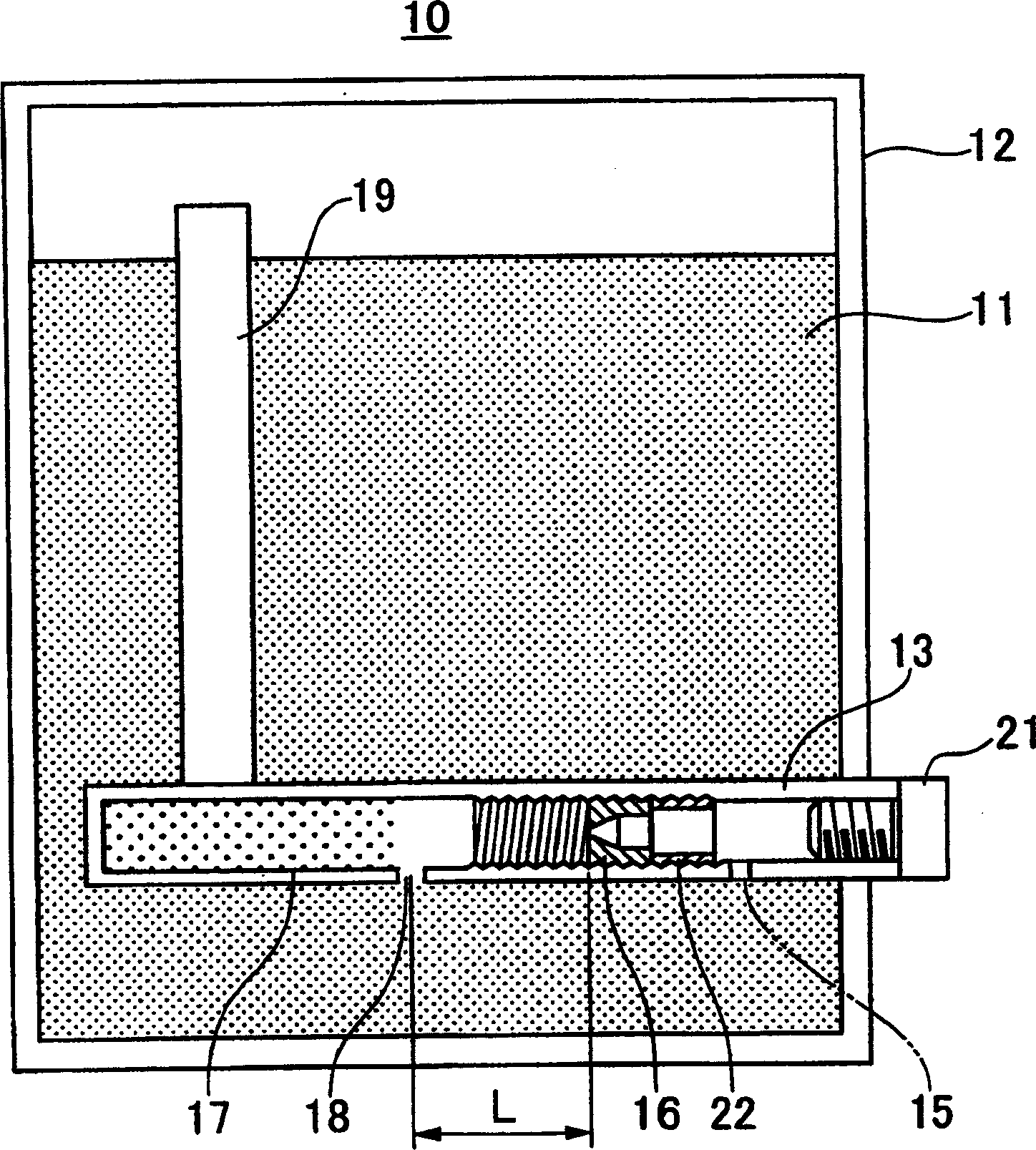

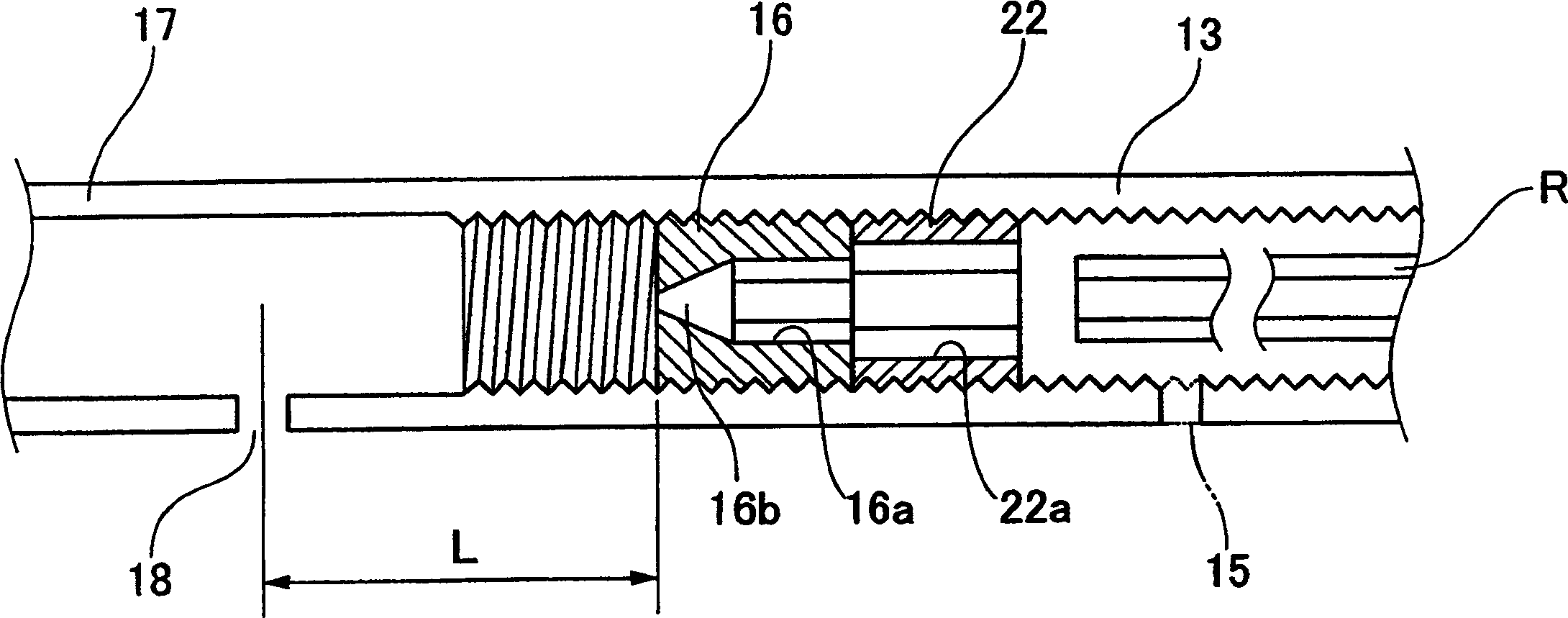

[0031] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a cross-sectional view showing an anti-slip material spraying device according to an embodiment of the present invention. Here, the anti-slip material injection device 10 is provided with the following parts: the anti-slip material storage container 12 storing the anti-slip material 11; the air introduction pipe 13 arranged in the anti-slip material storage container 12; The compressed air supply pipe 14 that is connected in the state of the direction and supplies compressed air. A spray hole 15 is formed downward on the air supply pipe 14 for spraying compressed air into the anti-slip material storage container 12 . A nozzle portion 16 is disposed in the air introduction pipe 13 . This nozzle part 16 is located in the above-mentioned air introduction pipe 13, is to increase the flow velocity of the compressed air supplied by the above-mentioned air int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com