Image signal process device

A technology of image signal processing and image signal, which is applied in the direction of image communication, TV, color TV parts, etc., and can solve problems such as clamp instability and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, embodiments of the present invention will be described with reference to the drawings.

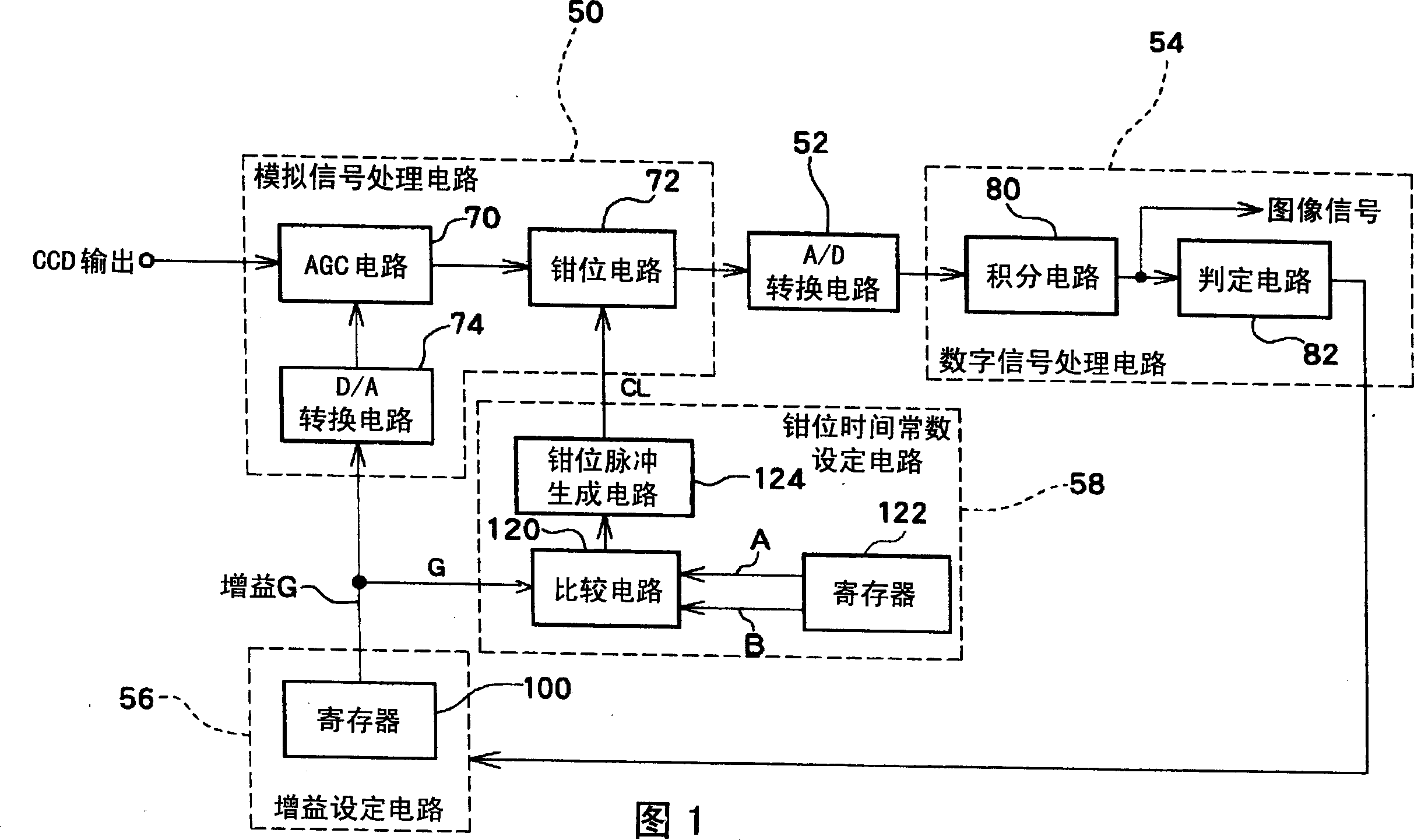

[0022] FIG. 1 is a block diagram showing a schematic circuit configuration of an image signal processing device according to an embodiment of the present invention. This device is composed of an analog signal processing circuit 50 , an A / D (Analog-to-Digital) conversion circuit 52 , a digital signal processing circuit 54 , a gain setting circuit 56 , and a clamp time constant setting circuit 58 .

[0023] The analog signal processing circuit 50 includes an AGC circuit 70 , a clamp circuit 72 , and a D / A (Digital-to-Analog) conversion circuit 74 . The AGC circuit 70 inputs an image signal from the CCD image sensor, and amplifies that image signal in accordance with the gain given from the gain setting circuit 56 . The clamp circuit 72 is a circuit that clamps the DC level of the image signal amplified on the AGC circuit 70, and is synchronized with the horizontal synchronizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com