Vehicle front-end struture

A technology for the front part of the vehicle body, which is applied to the upper structure, lower structure, vehicle parts, etc., can solve the problems of increasing production cost, adding components, and complex structure of the front part of the vehicle body, and achieves the effect of reducing cost and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The vehicle body front structure of the vehicle according to the present invention will be described below based on the illustrated embodiment.

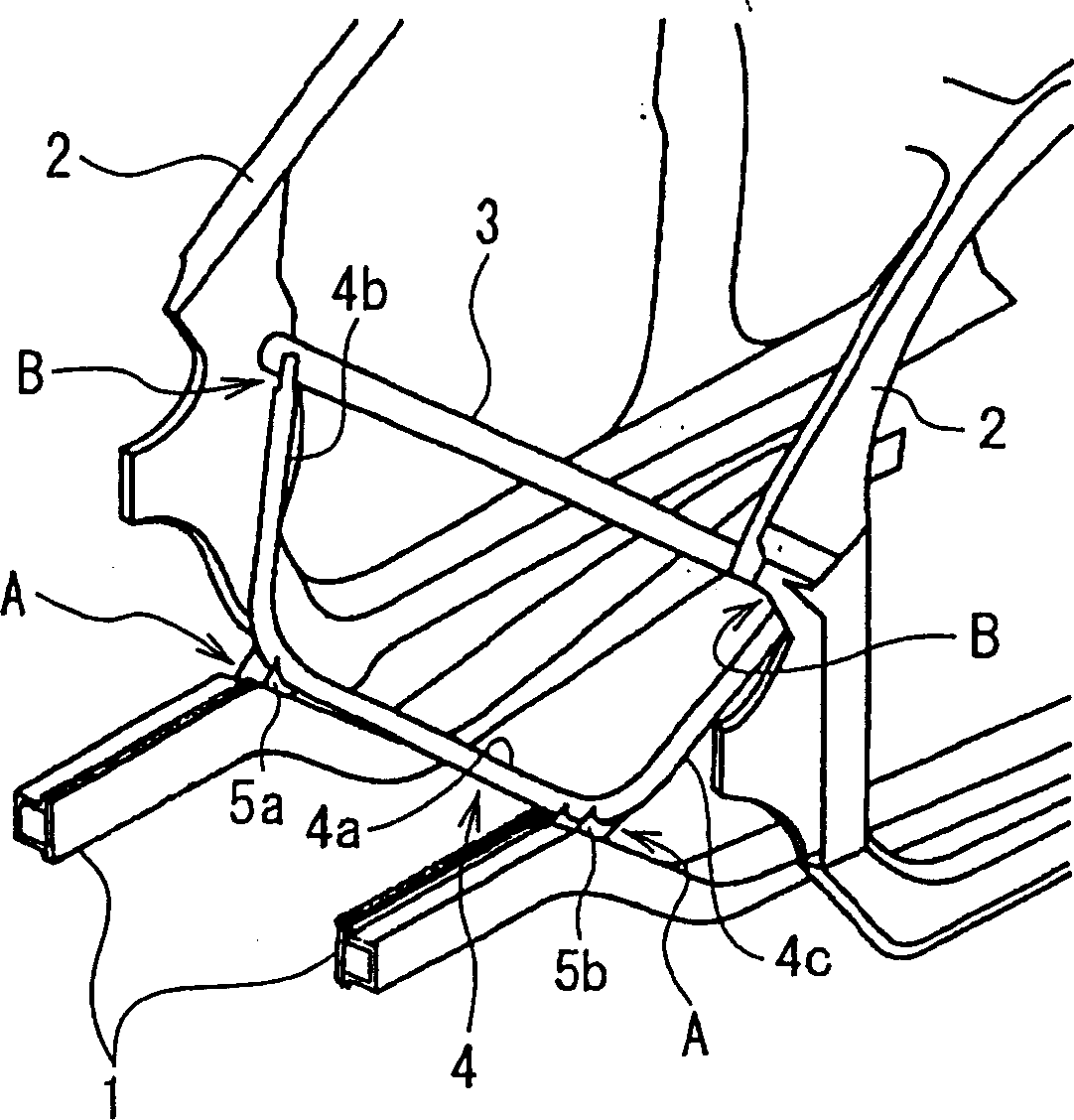

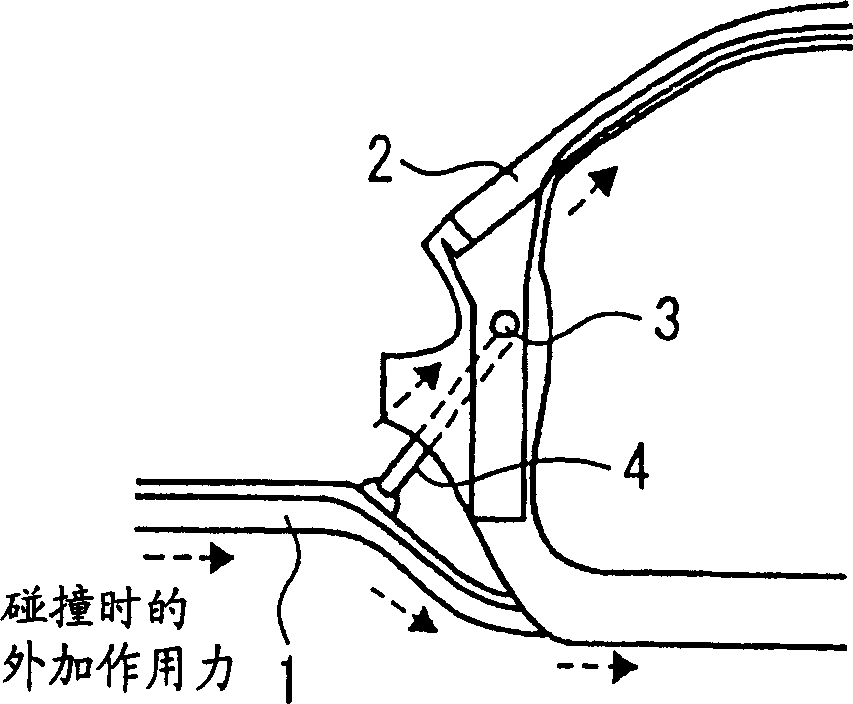

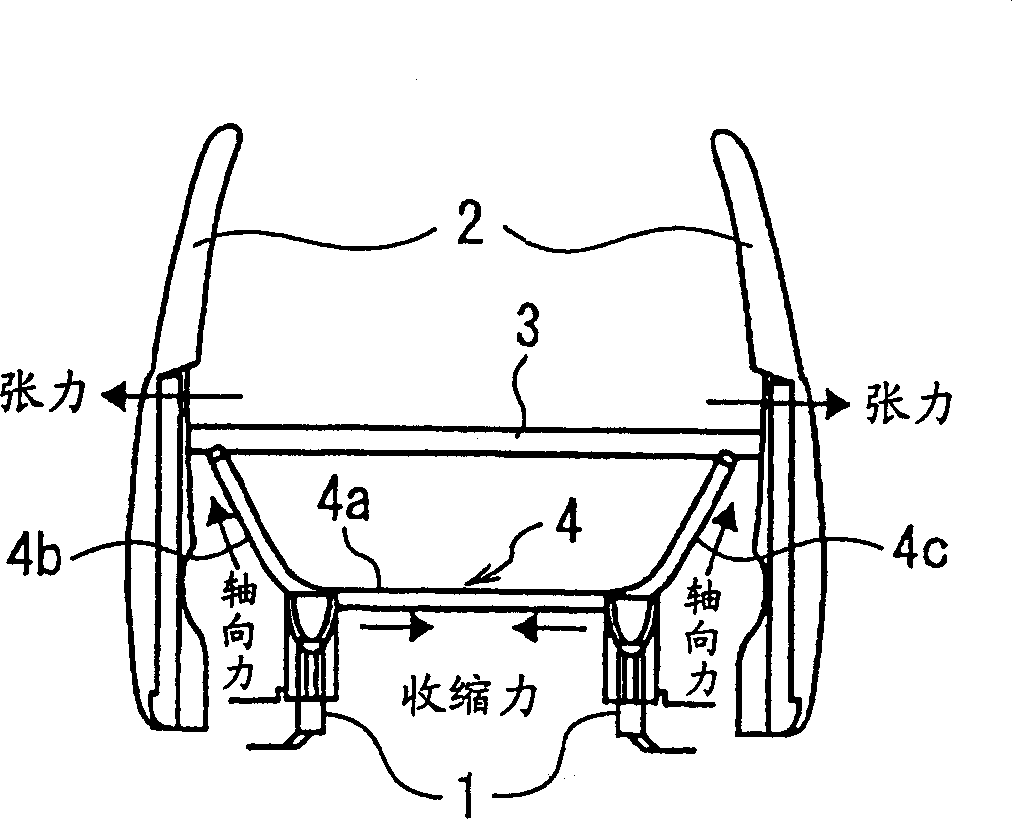

[0022] figure 1 is a perspective view of the vehicle body front structure of the embodiment of the present invention. Figure 2A and 2B It is a schematic diagram showing the structure and function of the front part of the vehicle body in the same embodiment of the present invention.

[0023] like figure 1 As shown, front side members 1 each having a closed cross-sectional structure are provided on left and right sides of a vehicle body front in such a manner as to extend in the longitudinal direction of the vehicle. A front floor cross member 3 made of a pipe extends between left and right front pillars 2 serving as vehicle body side walls.

[0024] The side member 1 is bent to be inclined downward from a front position which is a predetermined distance away from a position directly below the front floor cross member 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com