Flexible rotor low speed holographic dynamic balancing method

A flexible rotor and rigid rotor technology, applied in the field of holographic dynamic balancing, to achieve the effect of reducing multiple start-stop balancing tests, reducing balancing risks, and improving balancing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084] Balance scheme 1: Prioritize the balance force component

[0085] The balancing procedure for prioritizing balancing force components is as follows: Figure 4 As shown, the specific description is as follows:

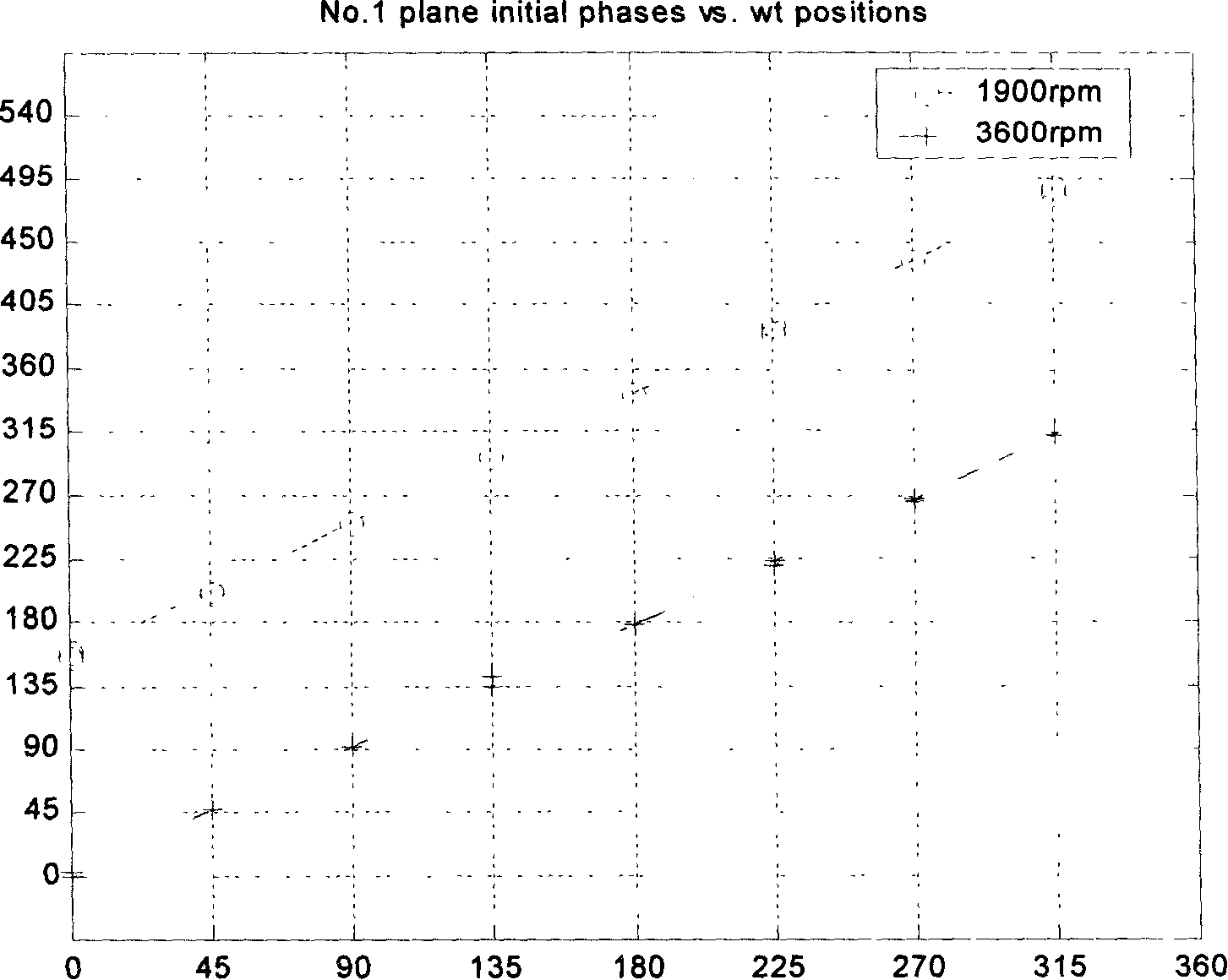

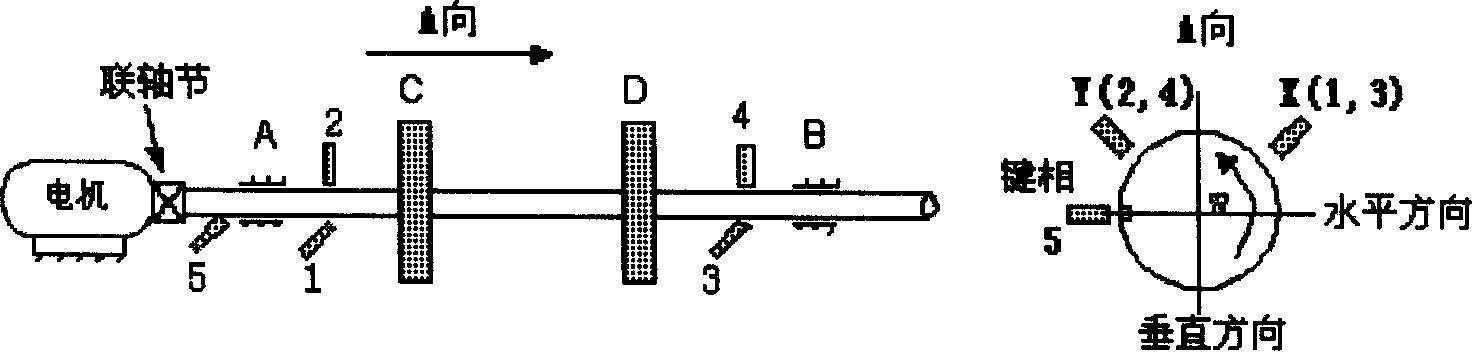

[0086]1. Measure the basic data. The working speed of the rotor is Ω=3600rpm, and the vibration at the working speed before shutdown is measured; the Bode diagram of the rotor shutdown process is obtained in the experiment, and ω=1900rpm is selected as the balance speed lower than the first-order critical value of the rotor; the measurement test bench is in The vibration in the cranking state is used as the runout, and the shaft vibration value must be deducted from the original runout; measure the original vibration of the rotor when ω=1900rpm (sampling frequency 2kHz, filter 1kHz, sampling points 2048);

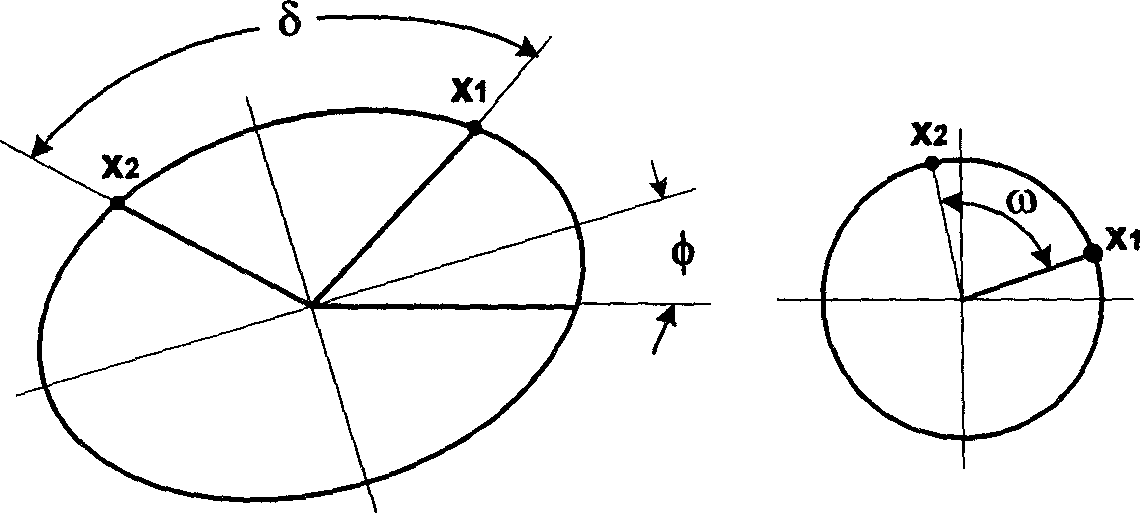

[0087] 2. After subtracting the original beating from the vibration data, make a three-dimensional holographic spectrum to obtain the initial phase point; at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com