A simple assembly and reusable balancing device and assembly method

The technology of a balancing device and an assembly method is applied to components of pumping devices for elastic fluids, non-variable pumps, pump components, etc., and can solve the problem that the balancing device cannot be used repeatedly, and the number of disassembly and assembly of fasteners is limited. Problems such as the influence of the rotor balance result, etc., achieve the effect of simplifying the rotor balancing process, saving the balancing cycle, and improving the efficiency of the rotor balancing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

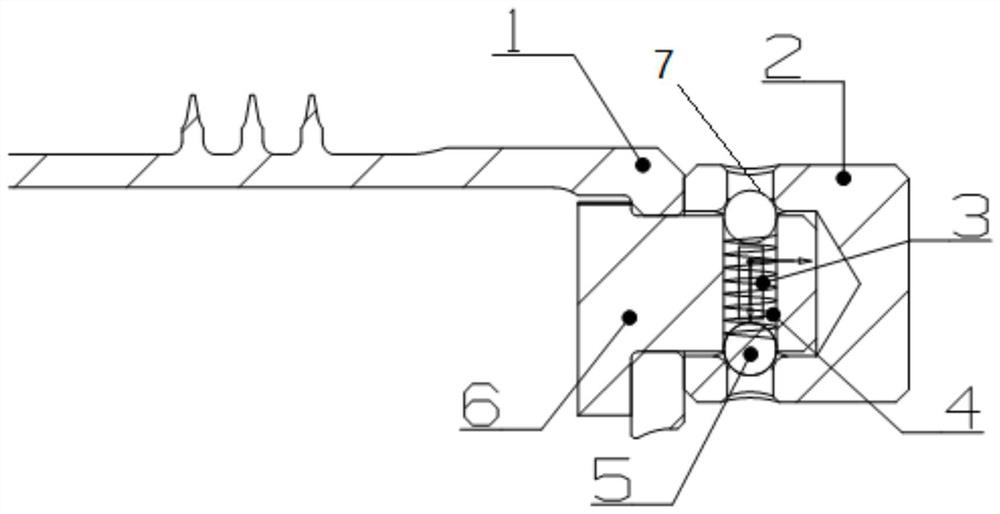

[0028] In this example, figure 1 Schematic diagram of the balancing device after assembly, such as figure 1 As shown, a simple assembly reusable balancing device is provided, the balancing device includes a rotor blisk 1 and a balancing weight assembly, the balancing weight assembly includes a balancing weight cap 2, a spring 3, a limiter 4, a ball I5 , ball II7 and balance block main body 6;

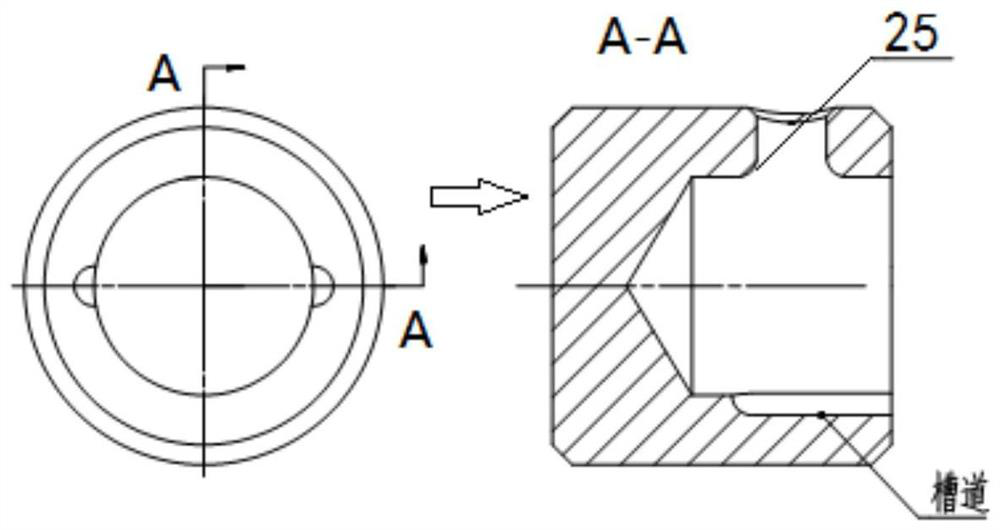

[0029] image 3 It is a schematic diagram of the structure of the balance block cap, such as image 3 As shown, the balance weight cap 2 is a cylindrical structure with countersunk holes, wherein the left figure is a top view, and the right figure is A-A cross-sectional view. The balancer cap 2 is provided with a first through hole, and a ball socket is provided at the intersection of the first through hole and the counterbore; the balancer cap 2 is provided with a groove perpendicular to the direction of the first through hole.

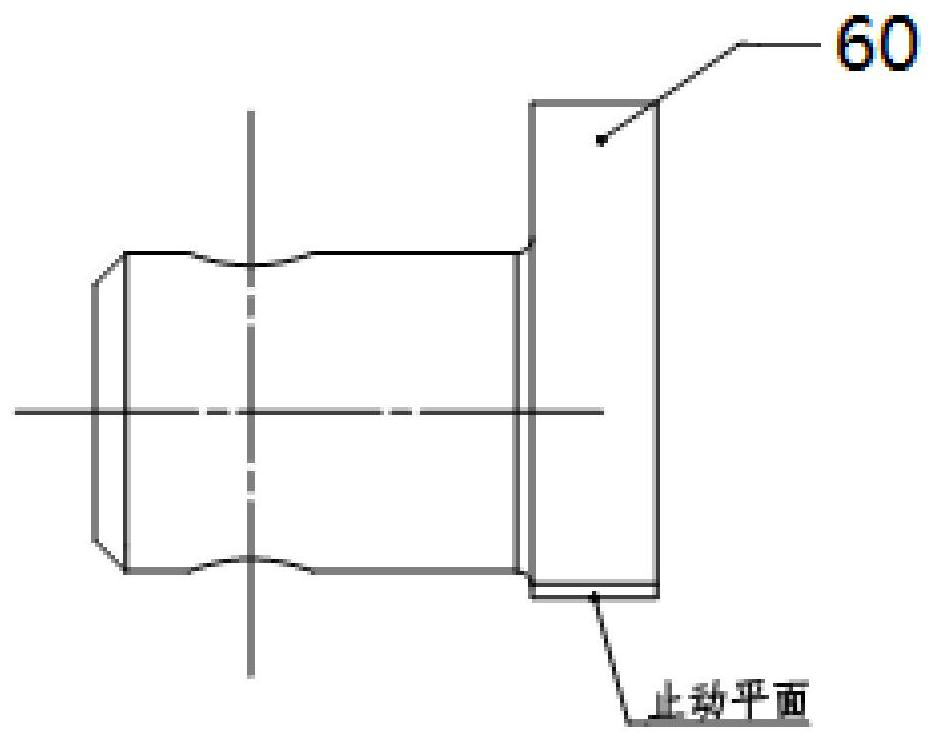

[0030] figure 2 It is a schematic diagram of the m...

Embodiment 2

[0036] This embodiment provides an assembly method of a rotor balancing device, using the above-mentioned balancing device, and the assembly method includes:

[0037] The fixed end of the balance weight body 6 passes through the installation through hole of the rotor blade disc 1, and the installation end of the balance weight body 6 is limited to one side of the rotor blade disc 1; the spring 3 is arranged in the second through hole, the ball I5, the ball II7 are located at both ends of the spring 3 and in the groove;

[0038] Rotate the balance weight cap 2, so that the ball I5 and the ball II7 roll from the groove to the ball socket 25, so that the spring 3 is in an extended state, so that the balance weight main body 6 and the balance weight cap 2 are connected.

[0039] Further, the stop plane on the mounting end of the balance weight body 6 is in contact with the rotor blisk 1 to prevent the balance weight body 6 from rotating when the rotor moves.

[0040] In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com