Method of produing carbonized coal and apparatus

A technology of carbonization and briquette, applied in the field of coal molding products, can solve the problems of easy softening structure of briquette, low strength of briquette, high crushing rate, and achieve the effects of easy transportation and storage, good combustion effect, and improved effective utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

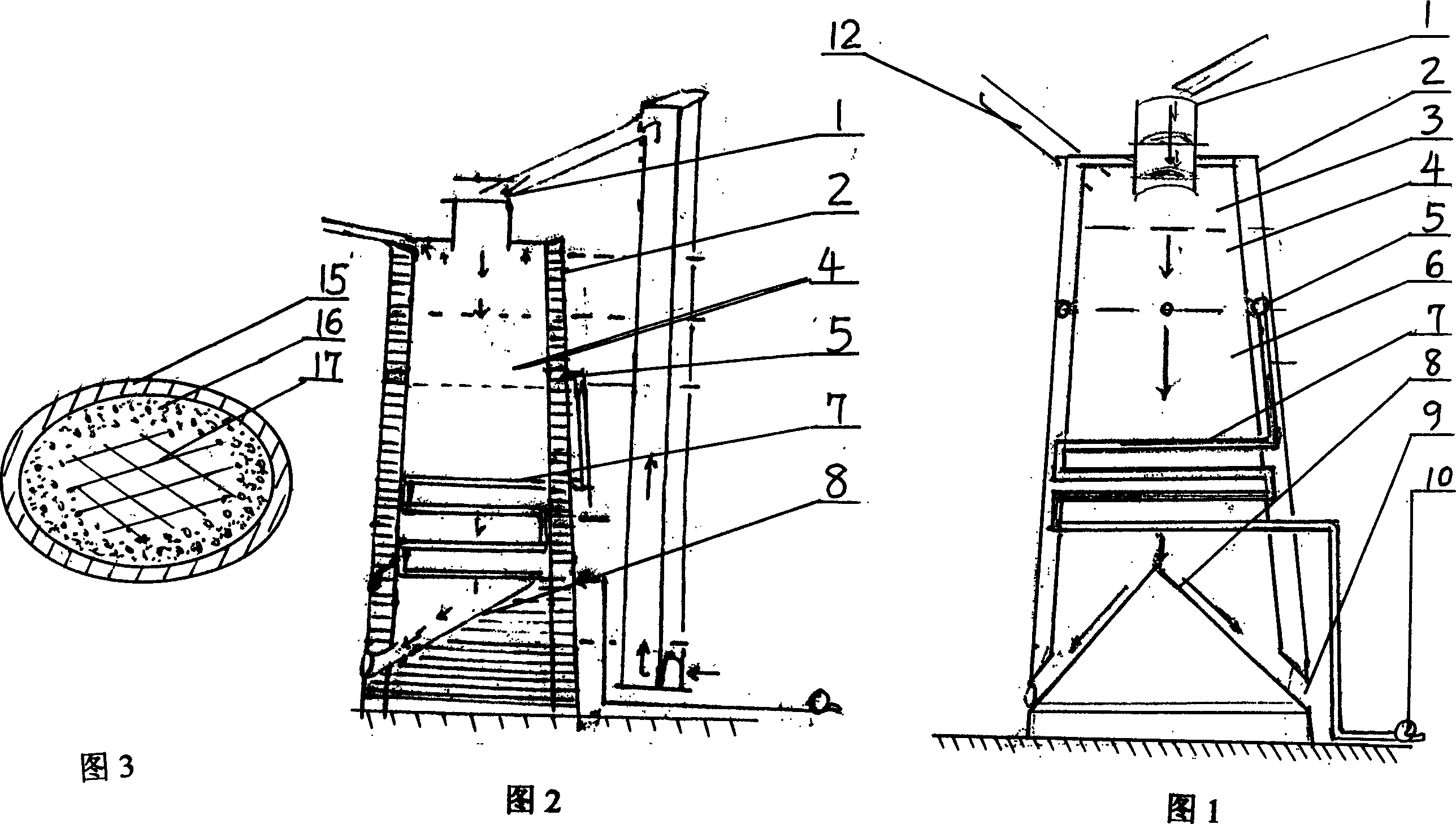

[0021] Example 1 The furnace body 2 of the present invention is 5.4 meters high, the inner diameter of the furnace bottom is 1.68 meters, and the inner diameter of the furnace top is 1.08 meters. The furnace body 2 includes three structural layers, wherein the inner furnace body is made of refractory bricks. The outer furnace body is made of ordinary building bricks. The middle is lined with vermiculite insulation. A cone 8 with a height of 1.5 is built in the lower part of the furnace body, the cone inclination angle is 55°, the cone surface is a concave surface and the lower part shrinks towards the outlet. The outer layer is a smooth surface of refractory cement. There are two discharge ports 9 at the bottom of the cone, and an openable and closable discharge door is installed on the outside of the discharge port. . When the discharge door is opened, the spherical briquette in the furnace automatically rolls down to the finished product box at the bottom. At 3.0 meters...

Embodiment 2

[0022] Example 2 The structure and size of the furnace body in this example are the same as those in Example 1. The support body at the lower part of the furnace body is a concave unilateral inclined surface with an inclination angle of 65°. There is a discharge port at the bottom of the concave surface. The lower part of the concave surface shrinks toward the outlet. The heat recovery device is a spiral tube.

Embodiment 3

[0023]Example 3 (tea furnace briquette): 70 parts of lean coal, particle size less than 3mm, 14% volatile matter and 15% ash content; 24 parts of fat slime, moisture content below 5%, 30% volatile matter and 20% ash content; The binder is 4 parts of bentonite, crushed to a particle size of less than 100 mesh, and 2 parts of quicklime, with a particle size of less than 100 mesh. Mix the above raw materials, add 8-10 parts of water, stir evenly, and shape with a pair of stick forming machine. The above-mentioned briquette is put into the furnace of Example 1, and the circular filler is used as a substitute below the annular tube of the furnace body. Ignite, gradually feed, form a coal-fired layer (ie heating layer) with a height of 1 meter and a temperature of about 600 ° C, open the lower furnace door, the circular packing is gradually released, and the upper briquette slowly descends. When the briquette descends to the annular tube At this time, it will enter the hot stewing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com