Method for modifying shape of involute gear

A technology of involute gears and involute teeth, which is applied in the field of gear processing, can solve the problems of increasing manufacturing difficulty and manufacturing cost, and the production efficiency cannot be effectively improved, so as to reduce the processing difficulty, facilitate mass production, and reduce meshing. Effects of noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

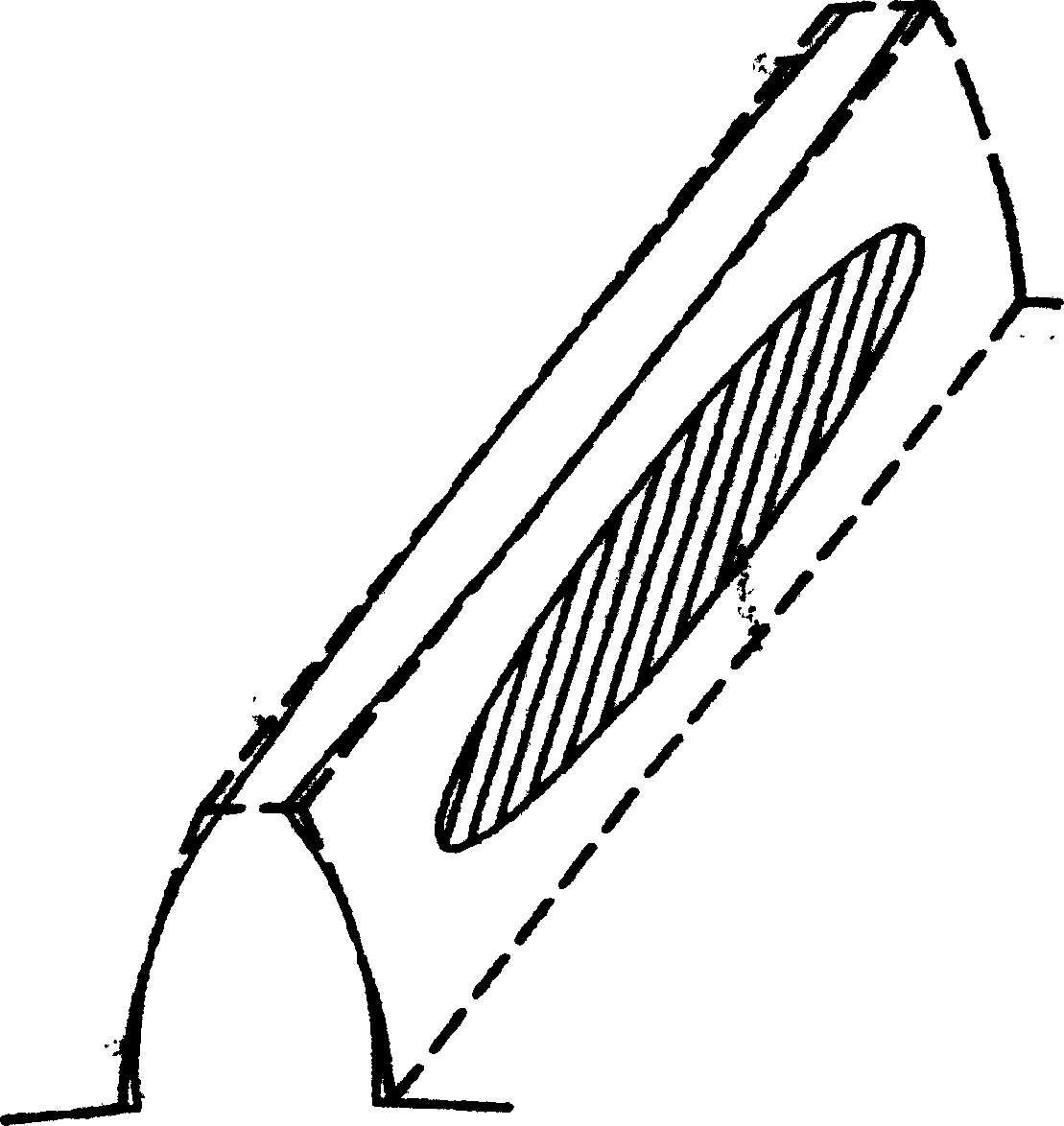

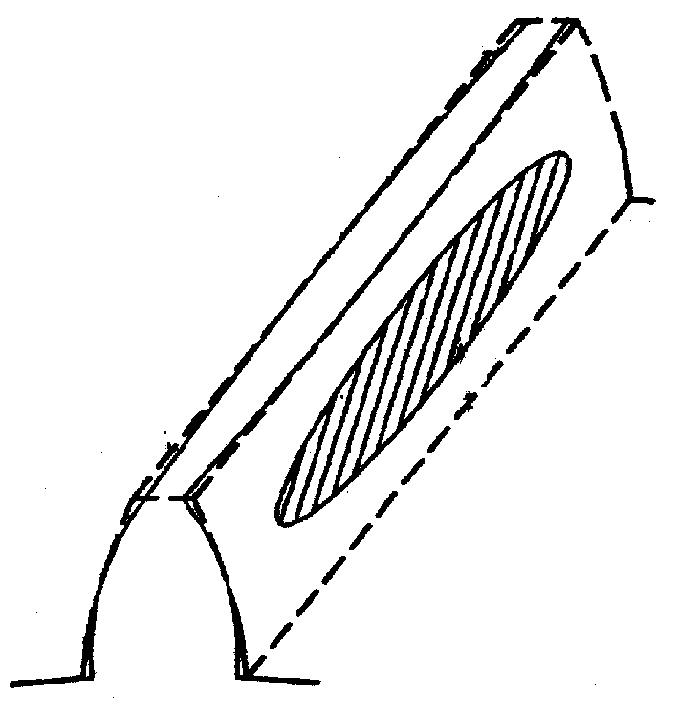

[0008] Embodiment of the present invention: first process the involute gear according to the traditional involute gear processing method, then carry out drum shape modification on the involute tooth profile of the involute gear, so that it is modified Compared with the involute tooth profile of the theoretical involute gear, the modified involute tooth profile curve of the modified involute gear is drum-shaped, and the tooth width direction of the involute gear is opposite to the The tooth profile is modified so that the tooth direction of the modified involute gear is a drum-shaped curve with a large middle and small ends, thereby obtaining a modified involute gear.

[0009] The gear modification of the present invention can be obtained by rolling directly, or after the gear is processed by rolling, it can be modified by a shaving knife, and the modification can be realized by shaving, or it can be realized by grinding.

[0010] Modification of hobbing processing: according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com