Precise forming powder in type of top tightened frame mount

A precision forming and powder press technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of equipment deformation, uneven density of parts, poor performance, etc., and achieve small tensile deformation and processing accuracy High, good performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

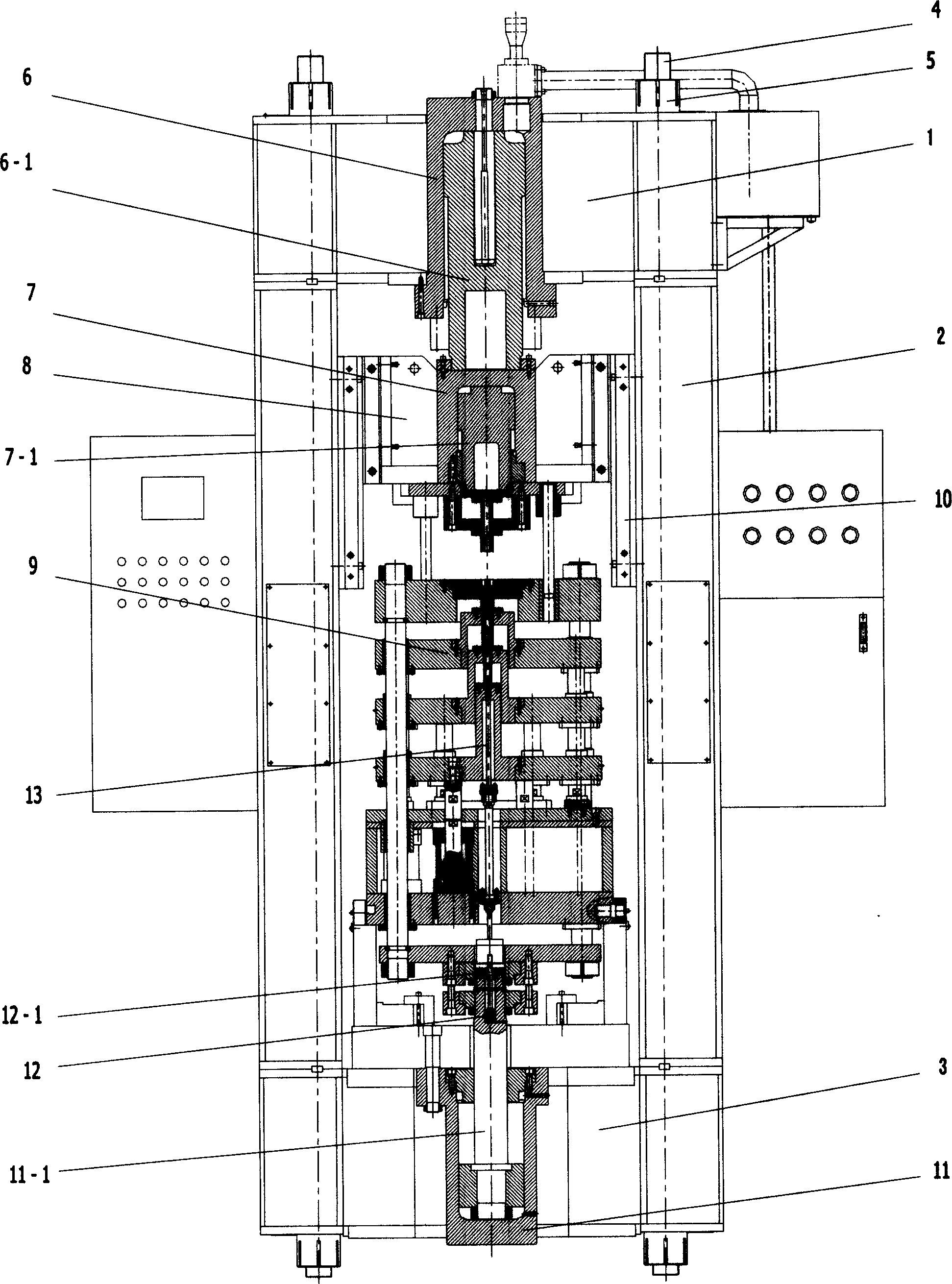

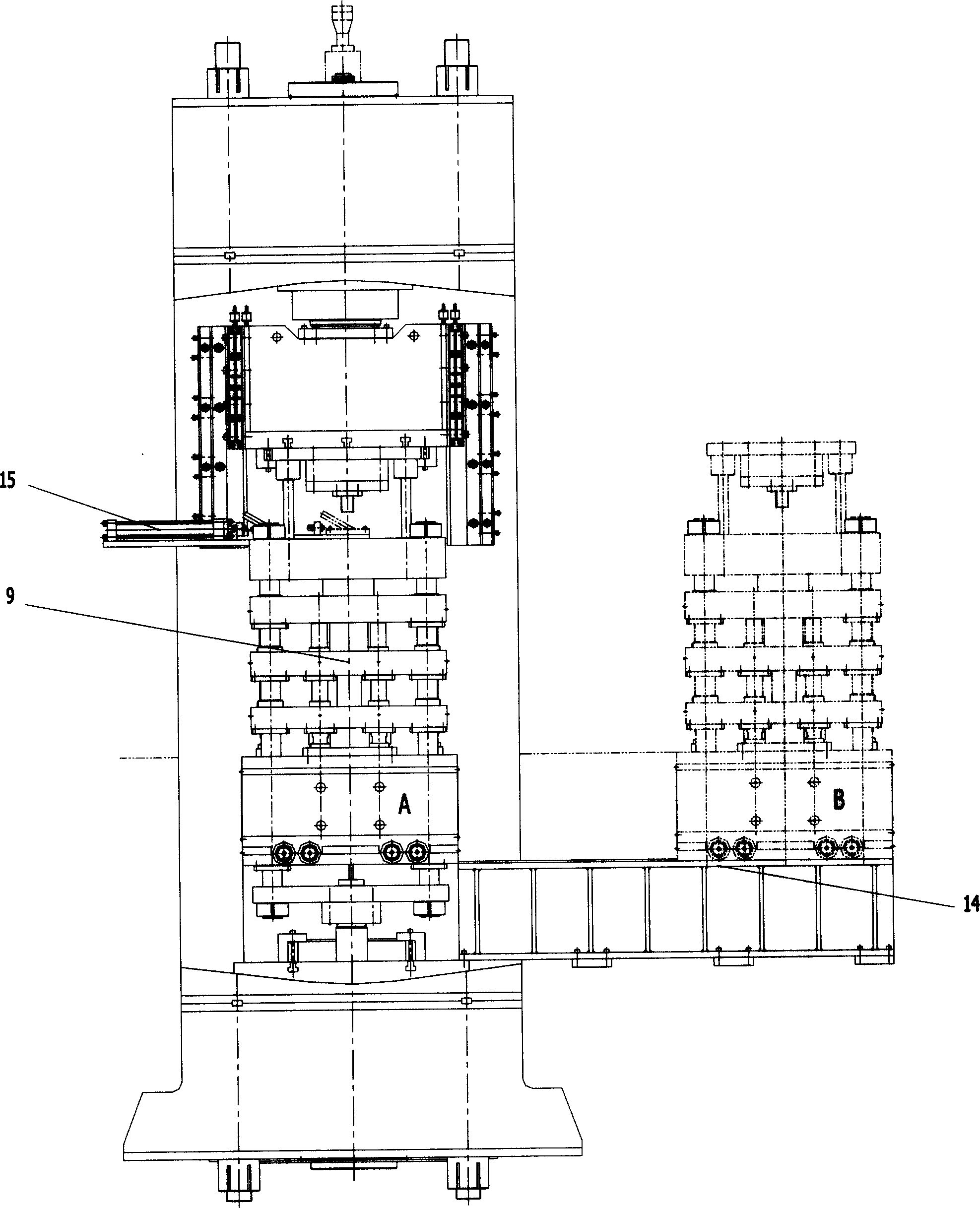

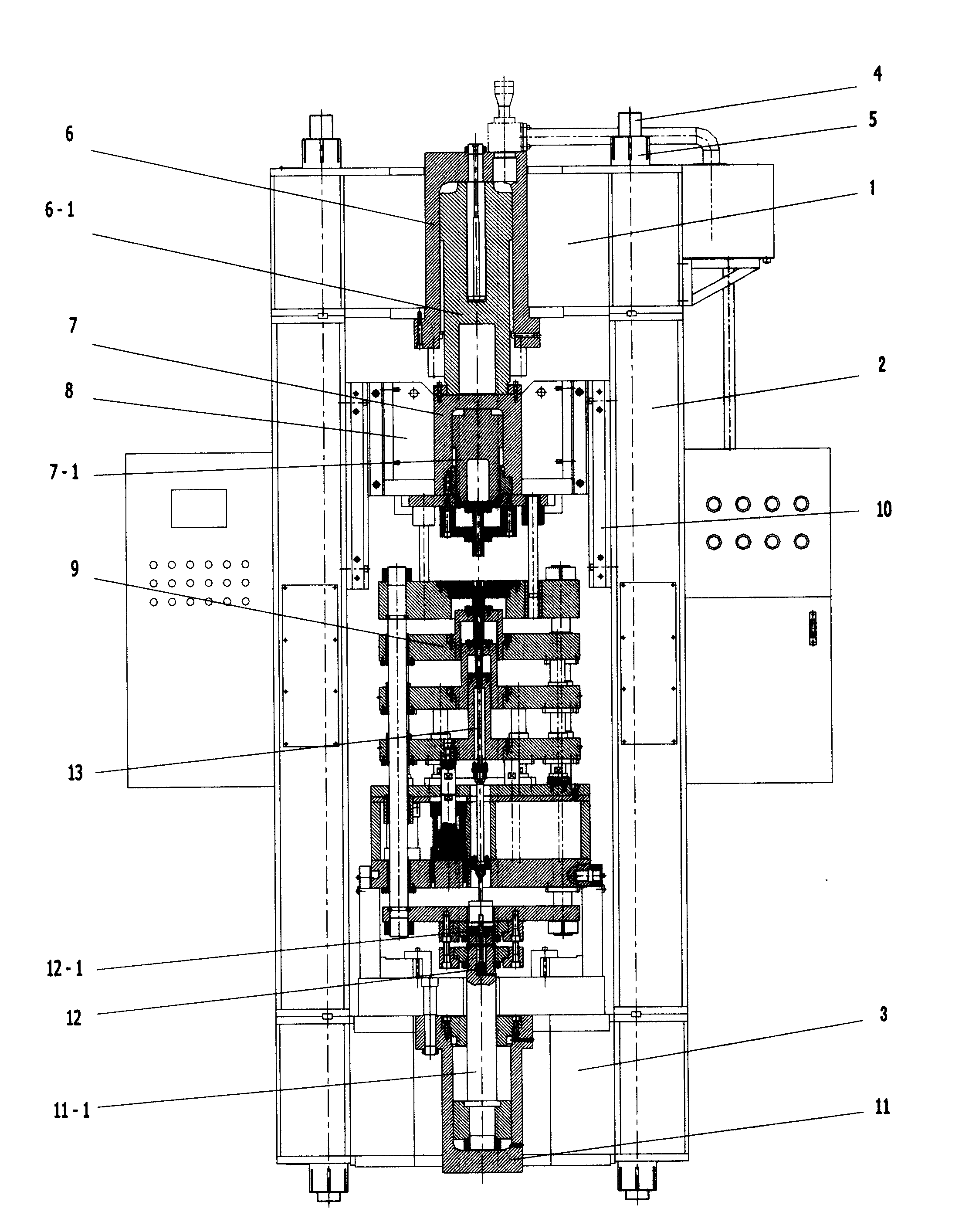

[0016] figure 1 A structural form of the present invention is shown, by figure 1 It can be seen that the pre-tensioned frame type precision forming powder press includes a closed frame body, a main cylinder assembly, and a bottom cylinder assembly. The lower part of the fuselage; the closed frame fuselage includes an upper beam 1, a column 2, a base 3, and a tie rod 4, the upper beam 1 is welded and fixed to the upper end of the column 2, the base 3 is welded and fixed to the lower end of the column 2, the upper beam 1, and the column 2 , the base 3 are connected to form a closed frame structure, the closed frame body is also connected with a tie rod 4, the tie rod 4 passes through the column 2, and the two ends are connected with nuts 5, and the whole closed frame body can be preloaded by tightening the nuts 5 at both ends Load, so that under the working state, the tensile stress on the column 2 is correspondingly reduced, which can increase the rigidity of the entire closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com