Nuclear reactor safety casing

A reactor and containment technology, applied in the field of containment, can solve the problems that the height cannot be reduced, the volume of the reactor containment 2 cannot be reduced, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

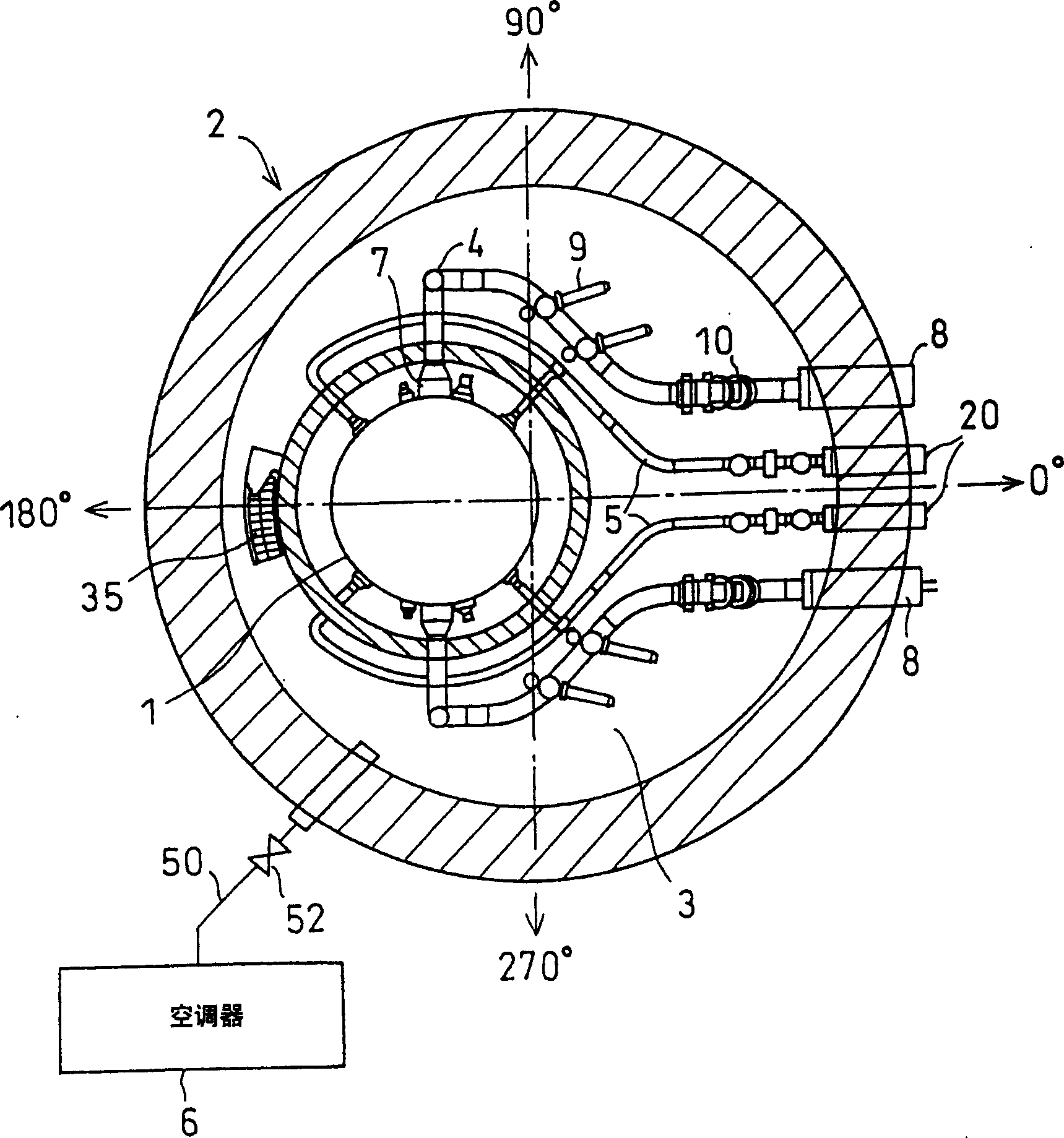

[0025] Refer below figure 1 with 2 , the first embodiment of the reactor containment vessel according to the present invention will be described. The reactor containment vessel 2 accommodates the reactor pressure vessel 1 . The shape of the horizontal cross section of the reactor pressure vessel 1 and the reactor containment vessel 2 is substantially circular. The penetration point 8 of the main steam pipeline and the penetration point 20 of the feed water pipeline are both arranged on the "0 degree" side. In this embodiment, the center of the reactor pressure vessel 1 is deviated from the center of the reactor containment vessel 2 along a direction of 180 degrees. That is, the space between the inner surface of the reactor containment vessel 2 and the outer surface of the reactor pressure vessel 1 is wider on the 0-degree side than on the 180-degree side.

[0026] exist figure 1 Among them, the dotted line along the direction of 0-180 degrees is the centerline (first a...

no. 2 example

[0043] Refer below image 3 with Figure 4 , the second embodiment of the reactor containment vessel according to the present invention is described. The reactor containment vessel 2 of this embodiment has an oval horizontal cross section. The length of the horizontal cross-sectional shape in the directions of 0 degrees and 180 degrees is greater than its length in the vertical direction.

[0044] exist image 3 , the dotted line along the 0-180 degree direction is the major axis (first axis) of the reactor containment vessel 2, and the other dotted line along the 90-270 degree direction is the short axis (the second axis) of the reactor containment vessel 2 axis). The center of the reactor pressure vessel 1 deviates from the second axis of the reactor containment vessel 2 along a direction of 180 degrees. The span of the inner surface of the reactor containment 2 on the first axis may not be the maximum span of the inner surface of the reactor containment 2 if the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com