Steam heating soybean milk maker

A soymilk machine and steam technology, applied in the field of steam heating soymilk machine, can solve the problems of damaging the working performance of the motor, reducing the service life of the motor, increasing the working temperature of the motor, etc., so as to improve the service life, avoid damage, and avoid heat damage to the motor system damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

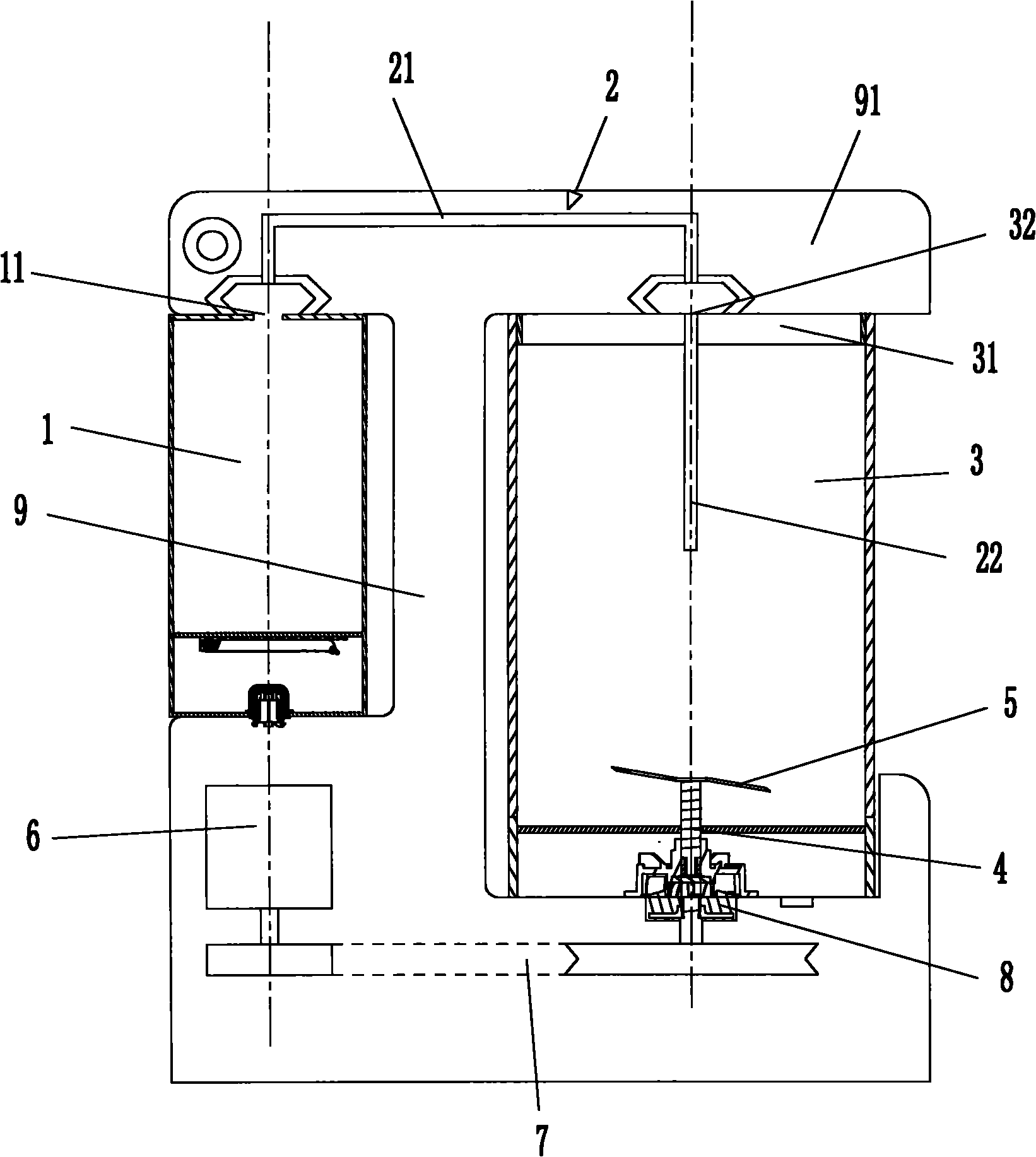

[0025] like figure 1 As shown, the present invention discloses a steam heating soymilk machine, comprising a steam generator 1, a steam pipeline 2, a cup body 3, a crushing device and a motor system, one end of the steam pipeline 2 is inserted into the cup body 3, and the other end is connected to the cup body 3 The steam outlet 11 of the steam generator 1 is connected, and the motor system is used to drive the pulverizing device, which is installed in the cup body 3, the pulverizing device is located at the bottom of the cup body 3, and the motor system is installed on the bottom of the cup body 3 sideways.

[0026] The steam generated by the steam generator 1 is transferred into the cup body 3 through the steam pipeline 2. As is well known, in order to achieve the effect of heating the slurry, the steam pipeline 2 needs to be inserted below the slurry liquid surface. In the present invention, when the slurry is heated, the slurry will generate steam and rise upwards, and th...

Embodiment 2

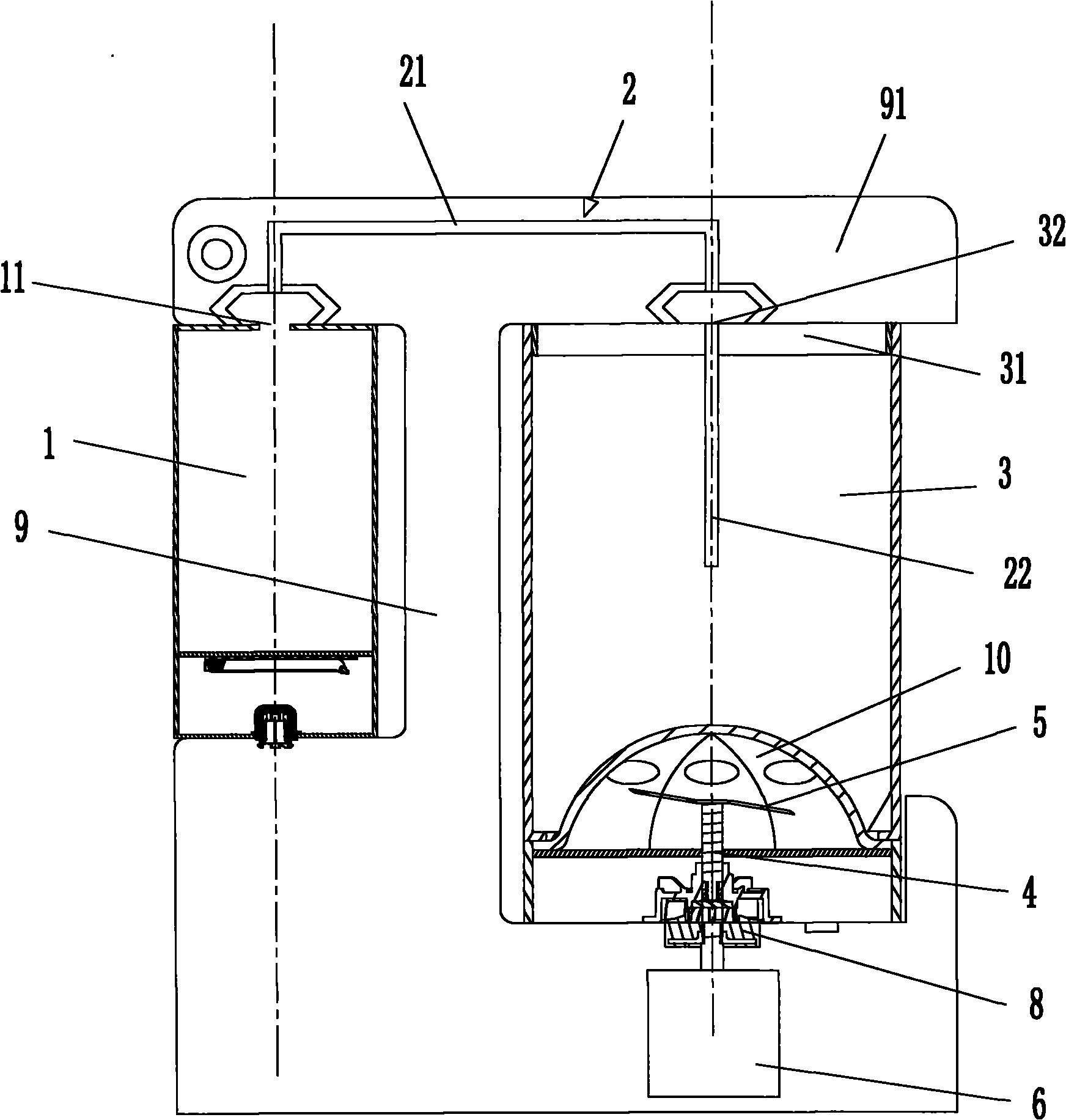

[0032] As a modified structure of Embodiment 1, this embodiment is similar to the structure of Embodiment 1, the difference is that, as image 3 As shown, the output shaft of the motor 6 is directly connected to the blade shaft 4 through a coupling 8 , and the motor 6 and its driving circuit are installed under the cup body 3 .

Embodiment 3

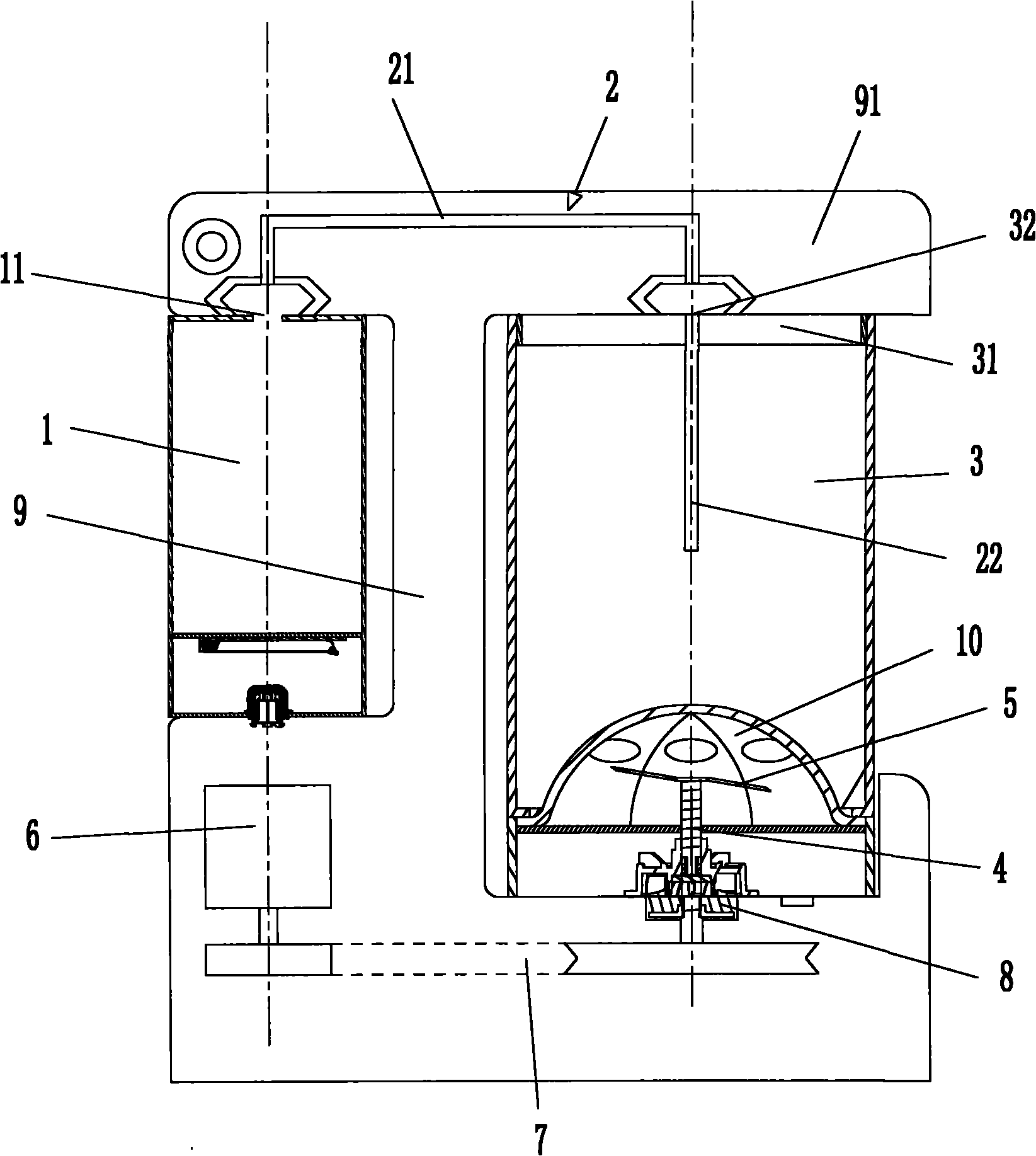

[0034] This embodiment is further limited on the basis of embodiment 1 or embodiment 2, specifically, as figure 2 As shown, the steam pipeline 2 includes a steam transmission section 21 and a steam output section 22, and the installation frame 9 is provided with an upper cover 91 movably connected with it, the steam transmission section 21 is arranged on the upper cover 91, and the steam output The section 22 is located in the cup body 3 , and the two ports of the steam transmission section 21 can be aligned with the through hole 32 and the steam outlet 11 respectively.

[0035] In this embodiment, when it is necessary to transfer the steam generated by the steam generator 1 into the cup body 3, it is only necessary to cover the upper cover 91; When the cover 91 is opened, due to the adoption of the lower structure of the motor system of the above-mentioned scheme at the same time, the use of the upper cover 91 is extremely convenient and light, avoiding the defects of heavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com