Manufacturing method of carbon nano tube paper

A carbon nanotube paper and carbon nanotube technology are applied in the field of carbon nanotube paper preparation, which can solve the problems of difficult quality control of carbon nanotubes, loss of carbon nanotubes, and lack of carbon nanotubes, and achieve good environmental stability. , The effect of uniform texture and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

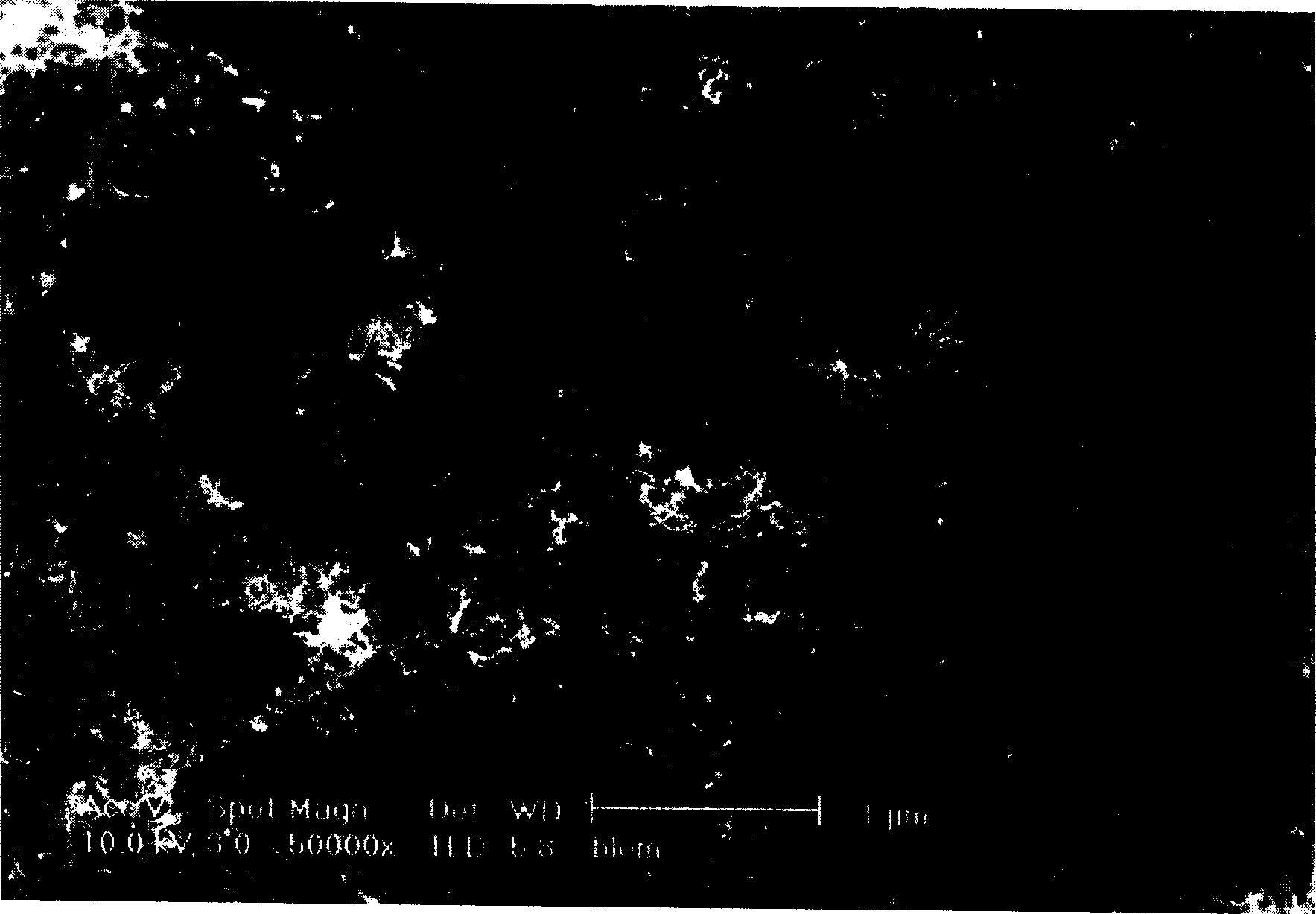

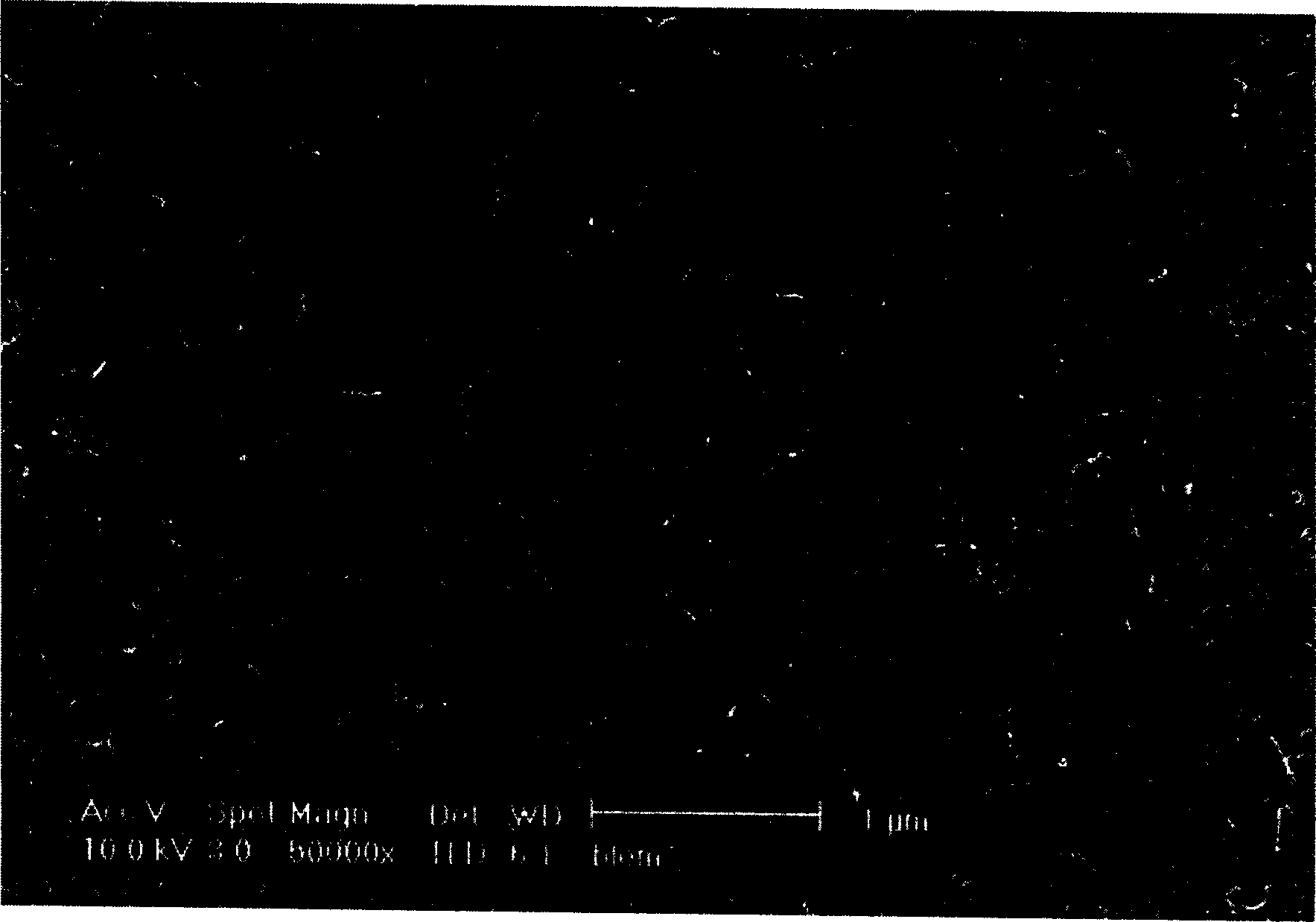

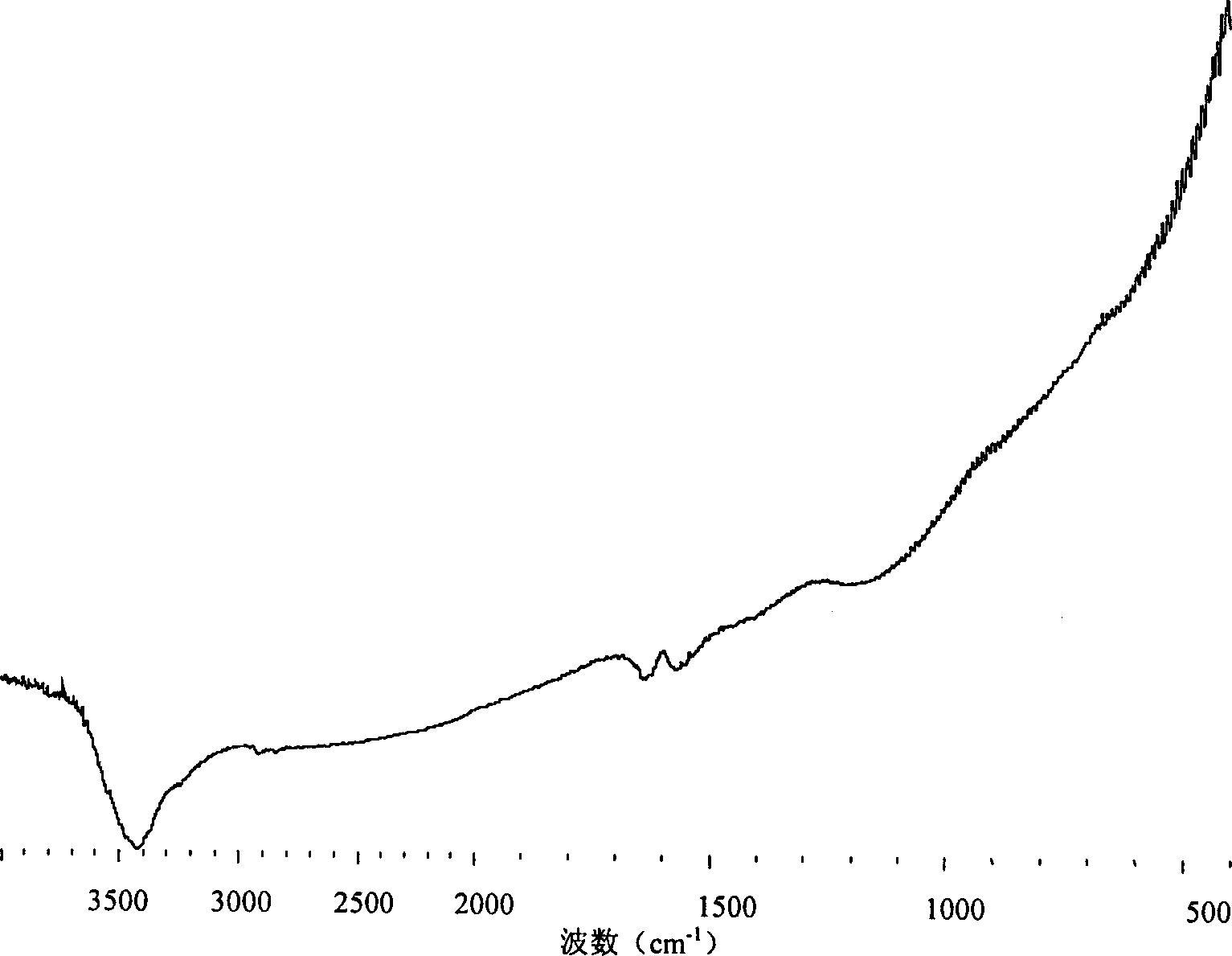

[0023] Weigh 1g of carbon nanotubes, pour it into a mixed solution of 1000ml of concentrated sulfuric acid and concentrated nitric acid (the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1), and at 70°C, ultrasonically vibrate and stir. After reacting for 24 hours, use Dilute with deionized water, filter, wash the filter cake with deionized water, and ultrasonically disperse the filter cake in deionized water to form a carbon nanotube solution; pour the carbon nanotube solution into a flat plastic container at room temperature drying under the hood to form carbon nanotube paper. Gained carbon nanotube paper, its thickness is 50 μm, has higher electrical conductivity, and its square resistance is 13Ω / 1cm, is far higher than the conductivity of carbon fiber paper (its thickness is 500 μm), and the square resistance of carbon fiber paper is 35Ω / 1cm . figure 1 is the structure of native carbon nanotubes, figure 2 It is the structure of carbon nano...

Embodiment 2

[0026] Weigh 1g of carbon nanotubes, pour it into a mixed solution of 1000ml of concentrated sulfuric acid and concentrated nitric acid (the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1), at 70°C, ultrasonically vibrate, and stir, after reacting for 24 hours, then Dilute with deionized water, filter, wash the filter cake with deionized water, ultrasonically disperse the filter cake in deionized water to form a carbon nanotube solution, pour the carbon nanotube solution into a stainless steel container with a flat bottom, and keep it at room temperature drying under the hood to form carbon nanotube paper. Gained carbon nanotube paper, its thickness is 70 μm, has higher electrical conductivity, and its square resistance is 10Ω / 1cm, is far higher than the conductivity of carbon fiber paper (its thickness is 500 μm), and the square resistance of carbon fiber paper is 35Ω / 1cm . Figure 5 It is the structure of carbon nanotube paper formed on a sta...

Embodiment 3

[0027] Embodiment 3. take by weighing 1g carbon nanotube, pour in the mixed solution (the volume ratio of concentrated sulfuric acid and concentrated nitric acid 3: 1) of 100ml vitriol oil and concentrated nitric acid, and stir, after reacting at room temperature for 48 hours, then use Dilute with deionized water, filter, wash the filter cake with deionized water, ultrasonically disperse the filter cake in deionized water to form a carbon nanotube solution, and pour the carbon nanotube solution into a stone container with a flat bottom. Dry to form carbon nanotube paper. Gained carbon nanotube paper, its thickness is 500 μ m, has higher electrical conductivity, and its sheet resistance is 17 Ω / 1cm, is far higher than the electrical conductivity of carbon fiber paper (its thickness is 500 μ m), and the sheet resistance of carbon fiber paper is 35 Ω / 1 cm . Figure 6It is the structure of carbon nanotube paper formed on a stone carrier. Compared with native carbon nanotubes, ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com