Centrifugal type dust collector

A vacuum cleaner and centrifugal technology, applied in the field of invention of centrifugal vacuum cleaners, can solve the problems of reducing the vacuuming effect, failure of the suction generator, etc., and achieve the effects of improving the vacuuming efficiency, preventing interference, and preventing scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

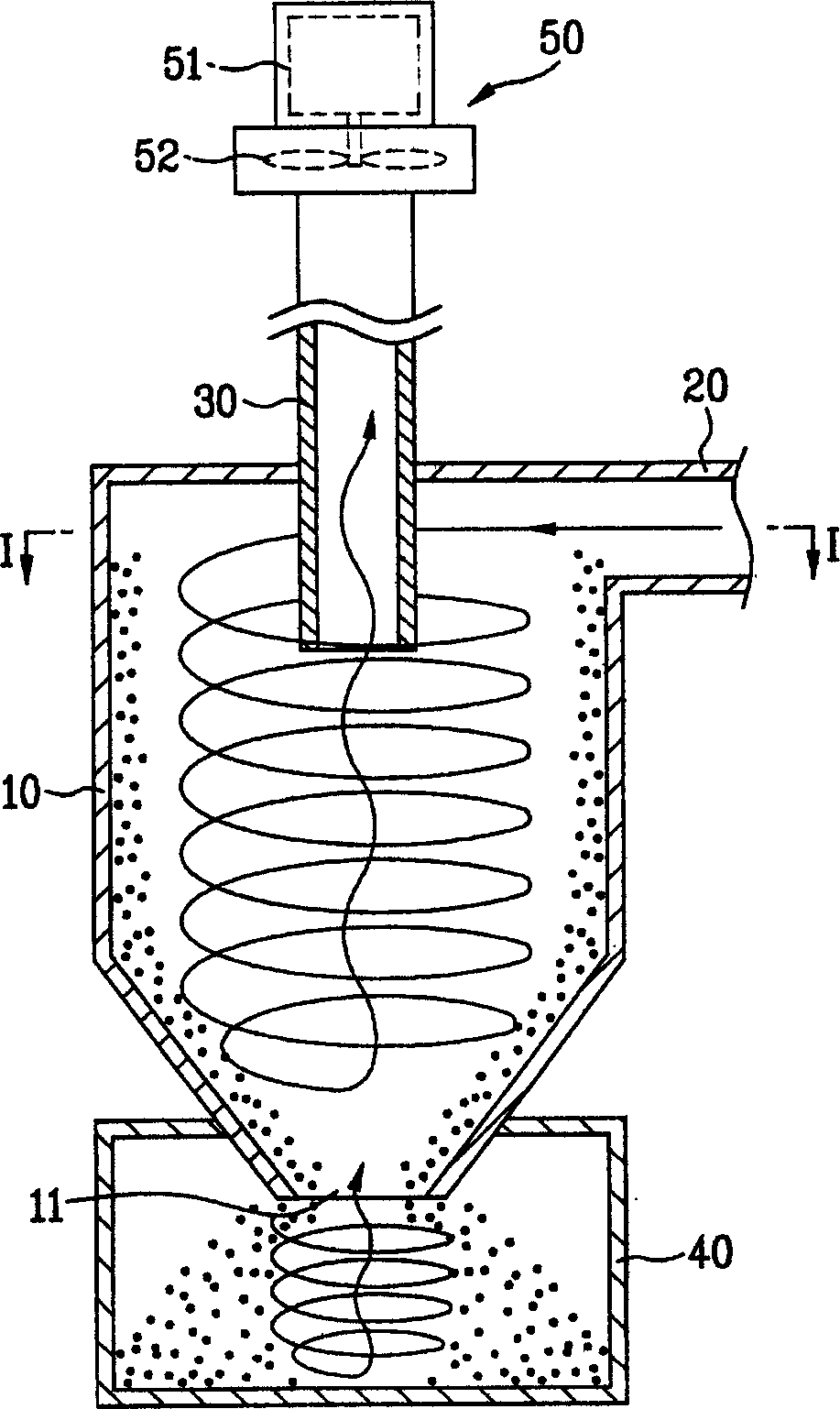

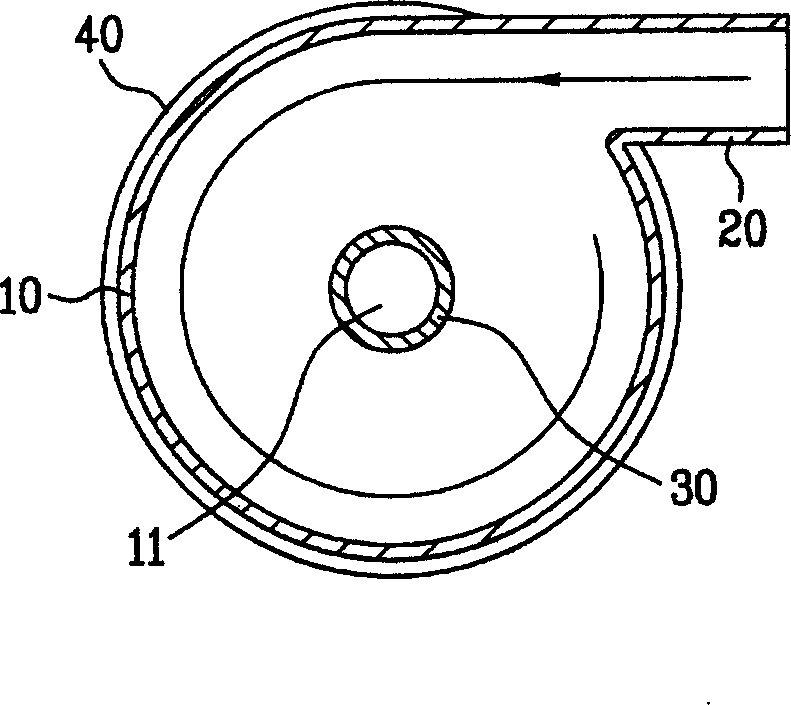

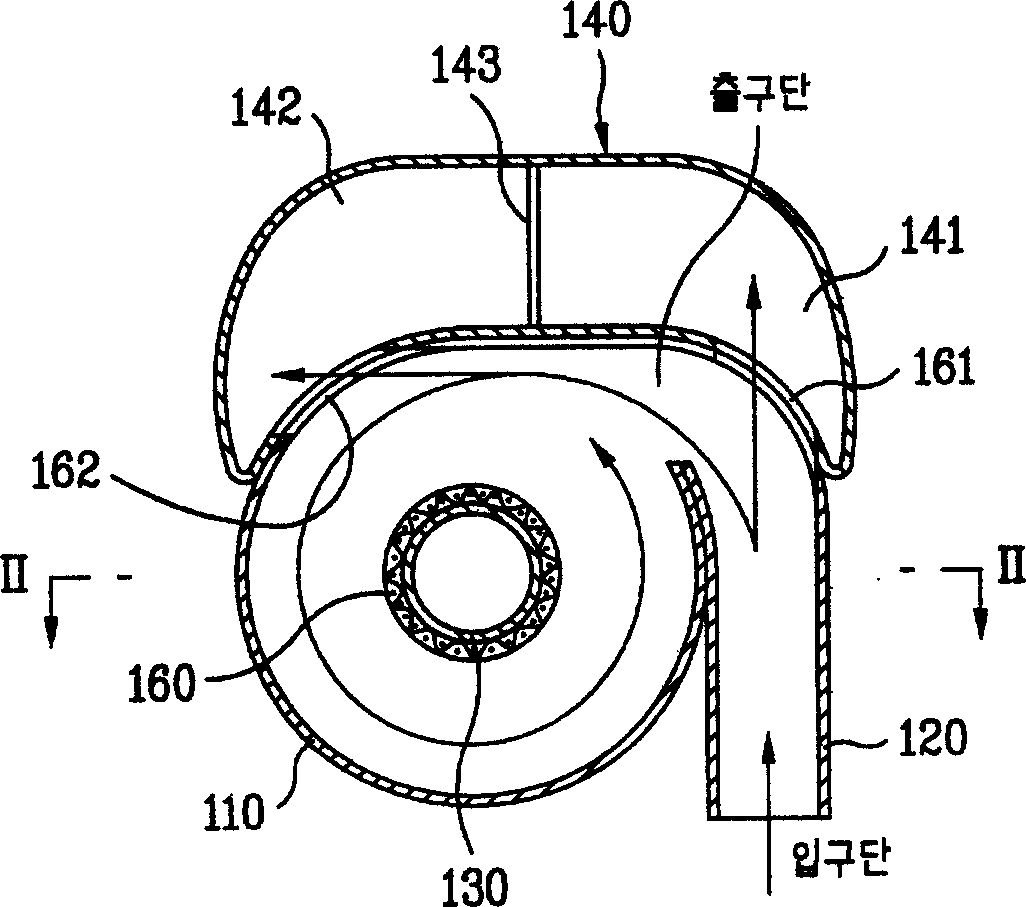

[0026] The present invention is a centrifugal vacuum cleaner, its structure includes a fuselage 110, a suction pipe 120 connected with one end of the periphery of the fuselage 110, which runs through one of the upper or lower surfaces of the fuselage and is connected to it. The air pipe 130; the first sewage discharge hole 161 is formed on the periphery of the fuselage 110 toward the suction pipe 120, communicates with the first sewage discharge hole 161, and collects the garbage discharged from the first sewage discharge hole is the first dust collection tube 141; On the periphery of the fuselage 110, a certain distance is formed with the first sewage discharge hole 161, and the second sewage discharge hole 162 formed on the air circulation path in the fuselage communicates with the second sewage discharge hole 162 to collect and discharge garbage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com