Purging method of semiconductor-manufacturing apparatus and manufacturing method of semiconductor device

A technology for a manufacturing device and a manufacturing method, which is applied to the field of purification technology after dry cleaning of a CVD device, can solve the problems of reduced productivity and insufficient purification, and achieves the effects of improving the operation rate, shortening the purification time, and improving the purification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

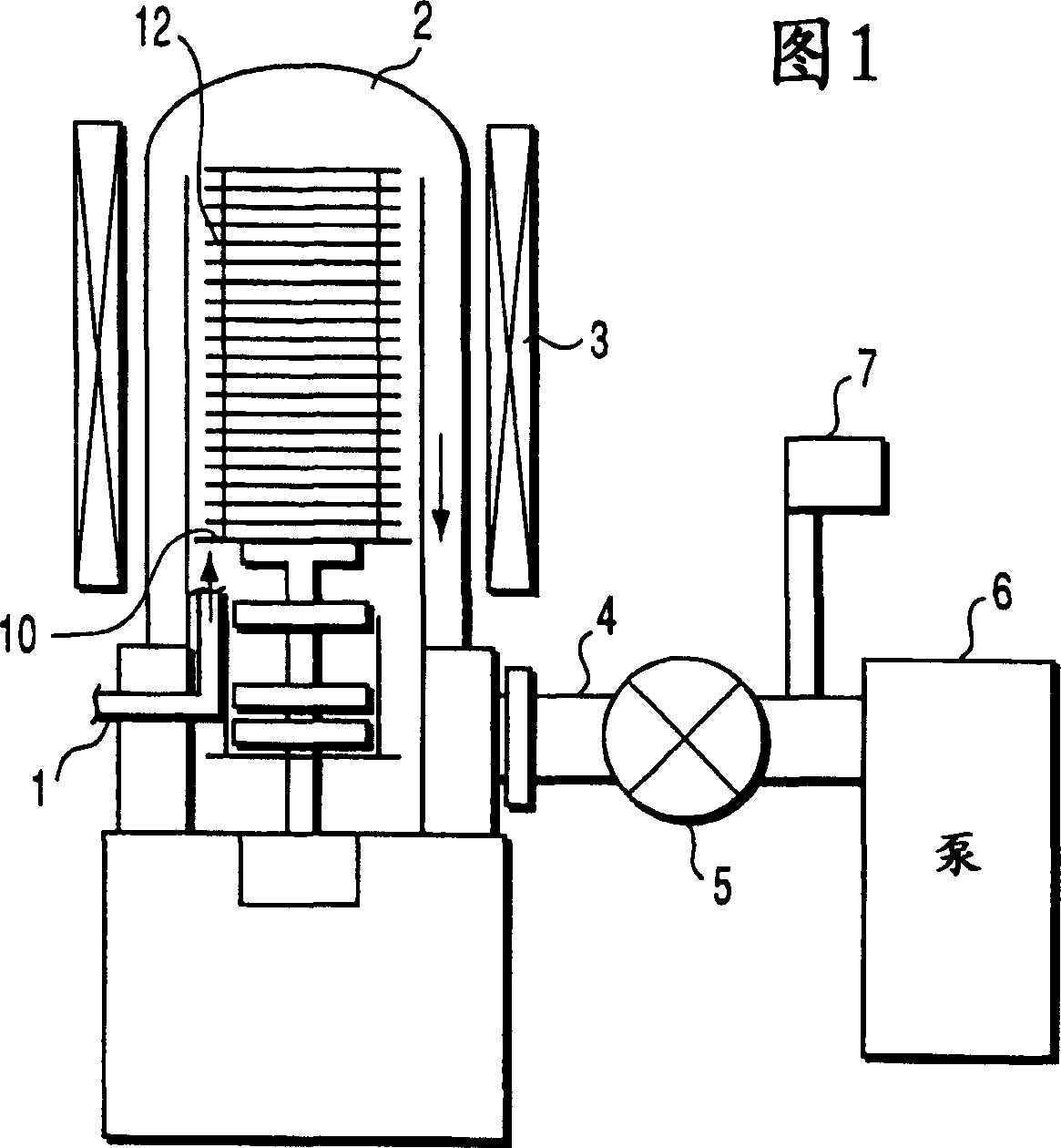

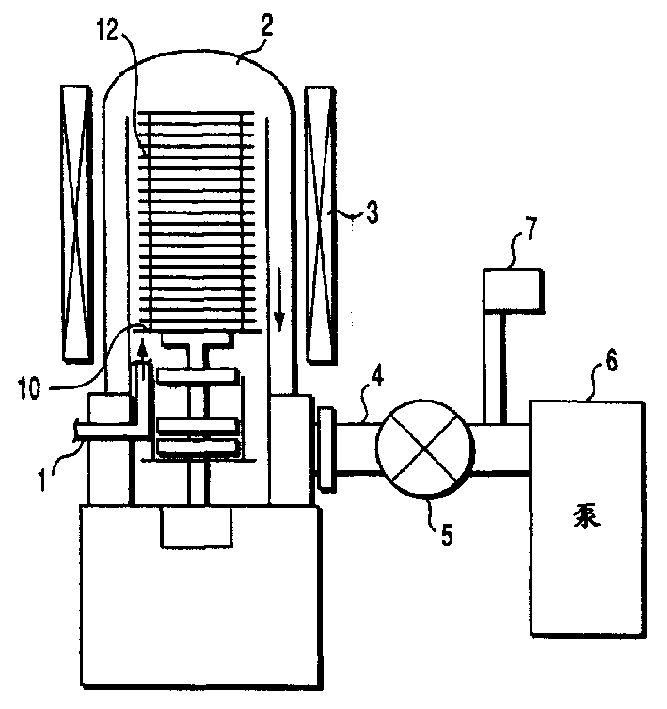

[0017] Referring to Fig. 1, Embodiment 1 will be described.

[0018] FIG. 1 is a schematic cross-sectional view of a vertical CVD apparatus as a semiconductor manufacturing apparatus. A boat 10 is provided in the vertical reaction chamber 2, and a semiconductor wafer 12 such as silicon is placed on the boat before the CVD process. In the lower part of the reaction chamber 2, a gas introduction port 1 is provided. From here, purge gas can be introduced into the interior of the reaction chamber 2 by operation of a mass flow control valve (not shown). A heater 3 is provided outside the reaction chamber 2 in order to heat the semiconductor wafer on the boat 10 in the reaction chamber 2 . A pump 6 is connected to the reaction chamber 2 through an exhaust pipe 4 having a pressure control valve 5, by operation of which the inside can be properly exhausted.

[0019] Using the CVD apparatus shown in FIG. 1, on the semiconductor wafer 12 on the boat 10, after forming a silicon film b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com