Chemical machinery grinding equipment

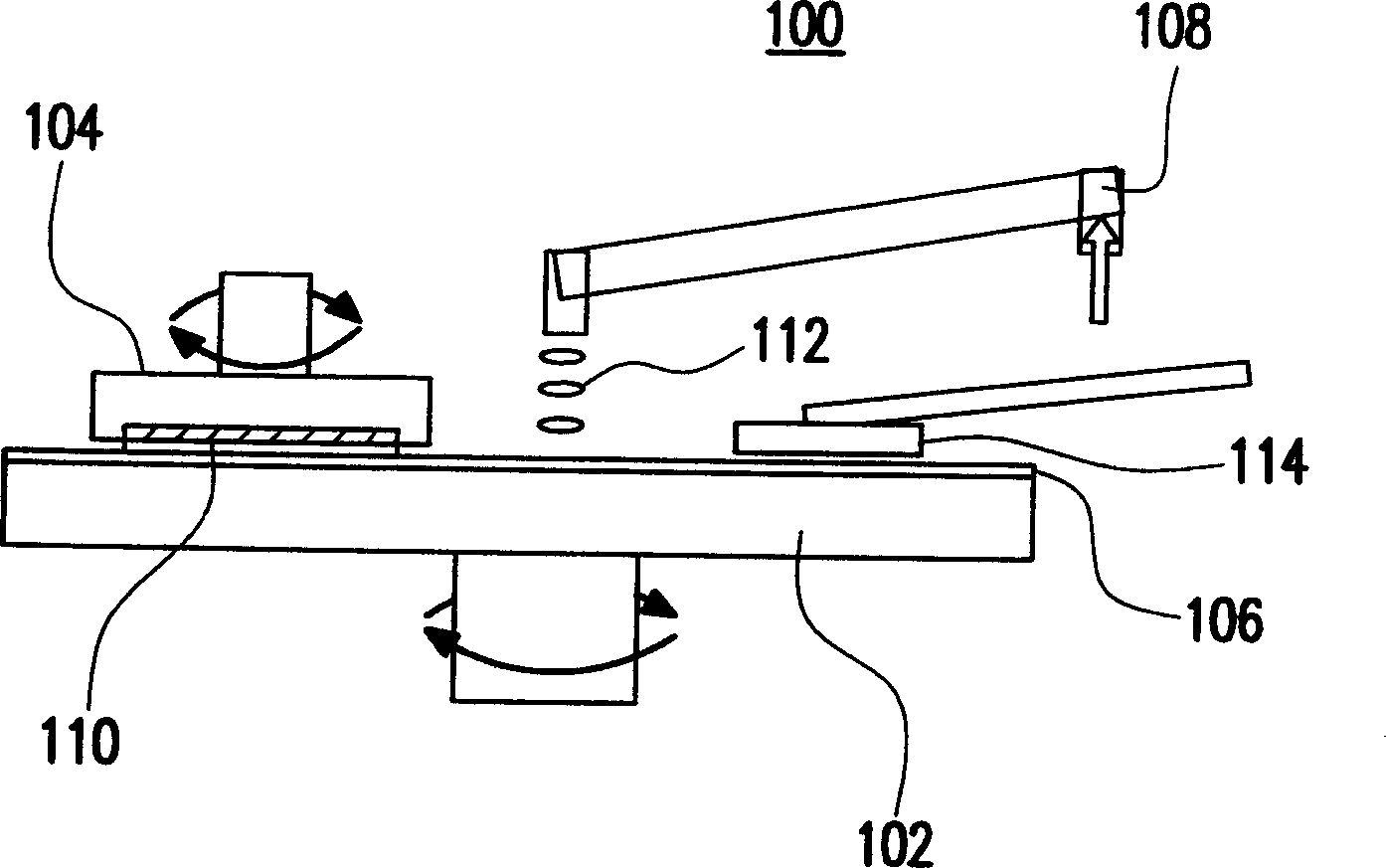

A technology of chemical machinery and equipment, applied in the field of chemical mechanical grinding equipment, can solve the problems of poor production line management efficiency, inability to further reduce size, increase production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

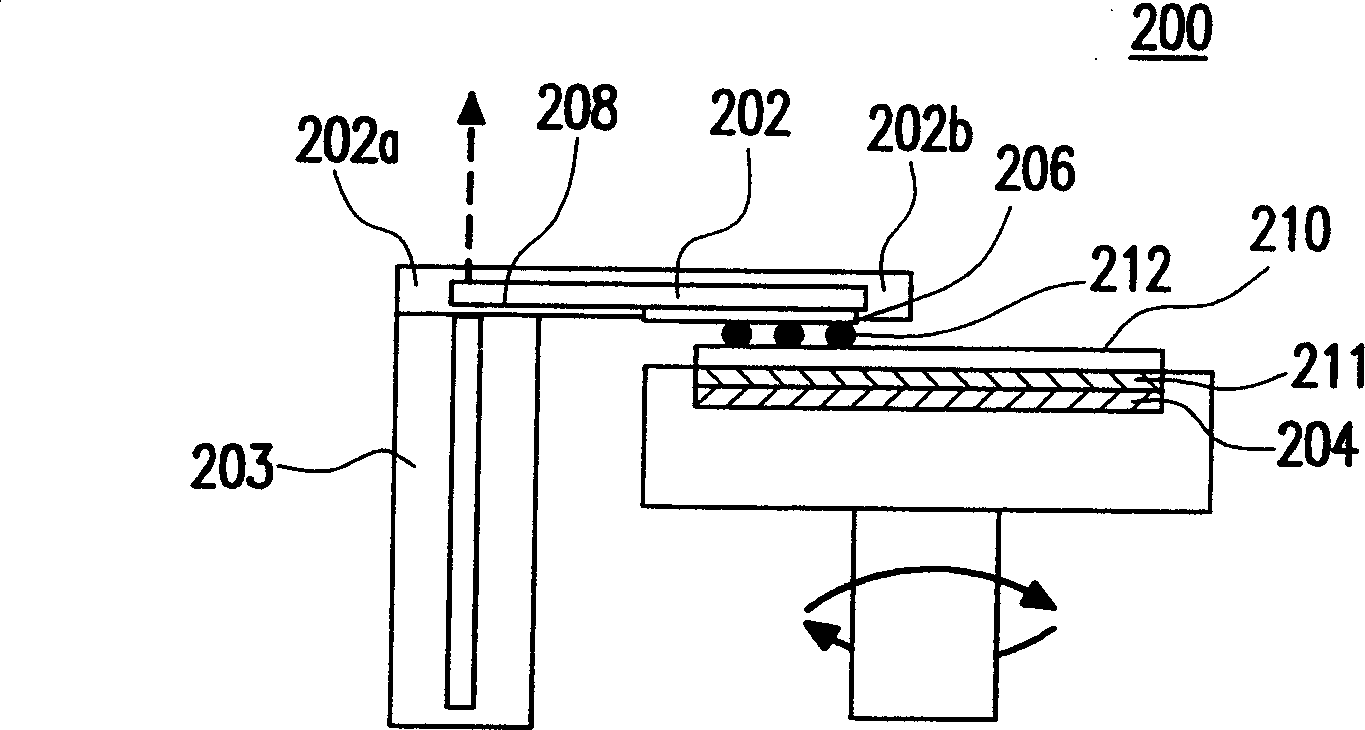

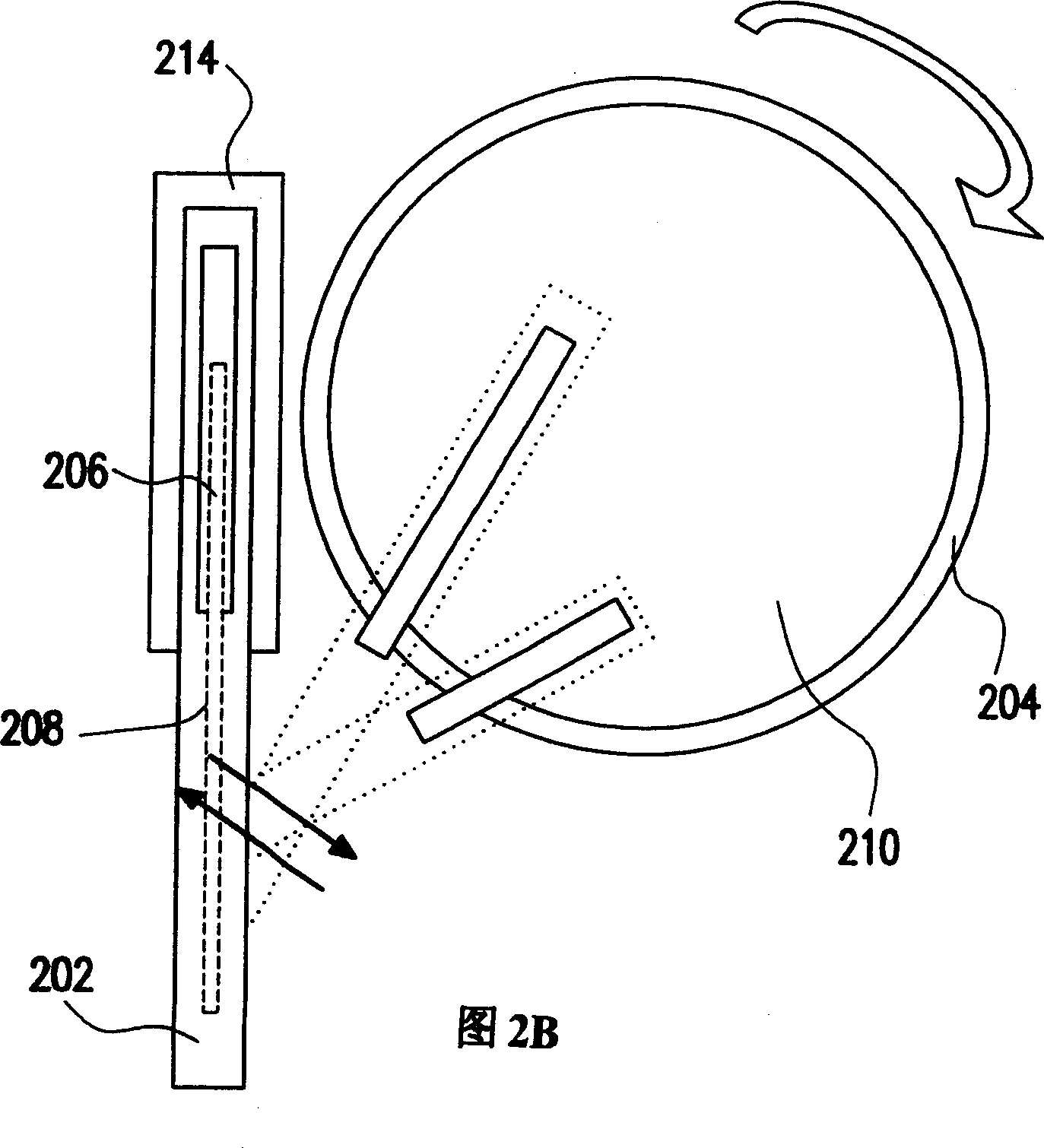

[0031] In order to make the above and other objects, features, and advantages of the present invention more comprehensible, a preferred embodiment will be described in detail below together with the accompanying drawings.

[0032] The design of the present invention can reduce the size of the CMP equipment by using a slender press plate, which is used as a grinding press plate, and the principle of the design is to make it into a slender shape or a rectangle. Please refer to Figure 2A 2B introduces a sectional view and a top view of a CMP device according to a preferred embodiment of the present invention. The core unit of the CMP device 200 includes an elongated grinding platen 202 and an automatically rotating wafer handle 204. The elongated grinding platen 202 is preferably elongated, and one end 202a of the grinding platen 202 is preferably fixed at a position around the wafer handle 204, and the elongated platen 202 can revolve around a rotation axis Z at the fixed end 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com