Belt tension adjusting apparatus and optical scanner using same

A technology for adjusting device and belt tension, which is applied in the direction of optical recording/reproduction, transmission, belt/chain/gear, etc., which can solve problems such as waste of time, cost, and complicated steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

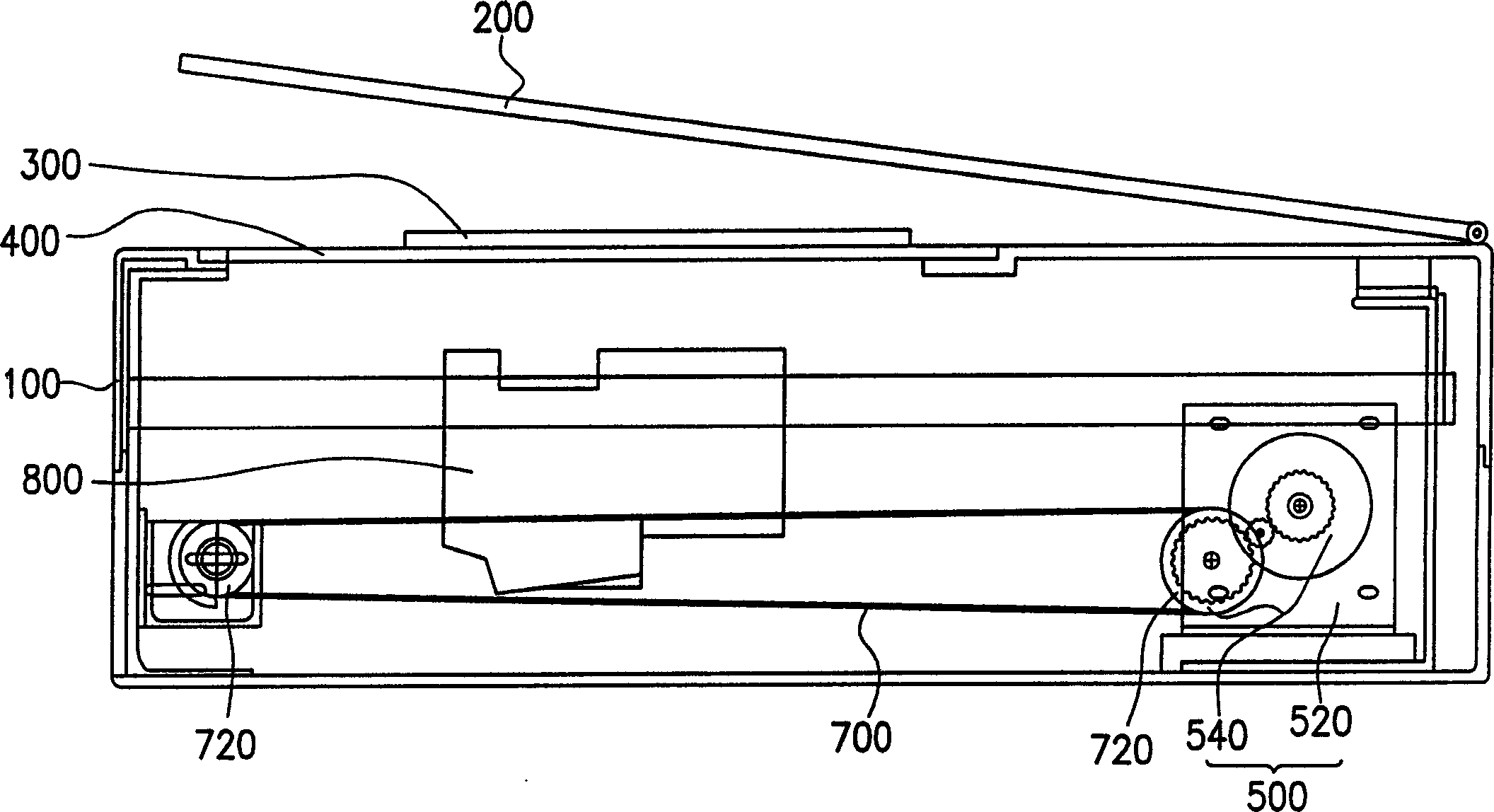

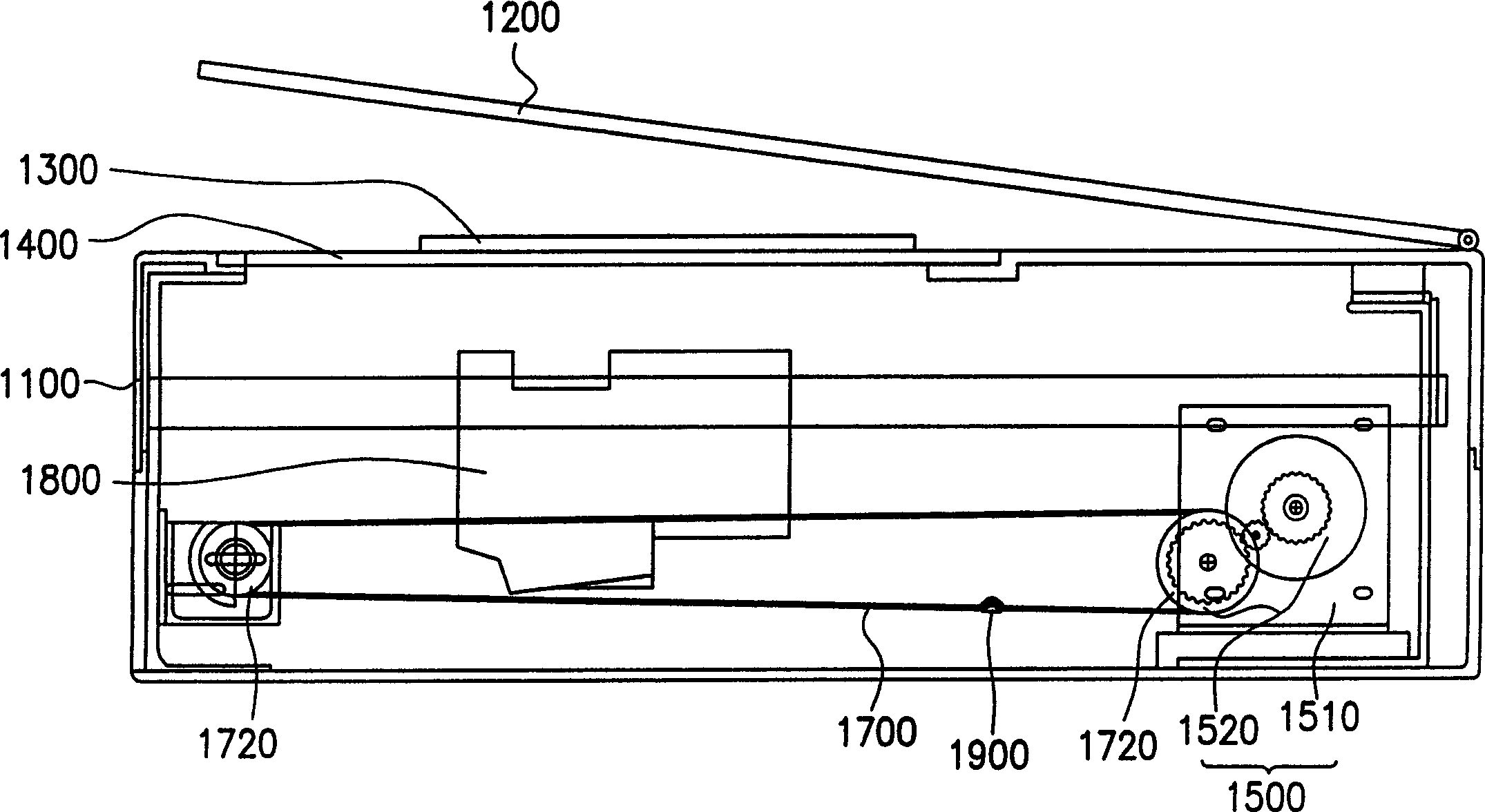

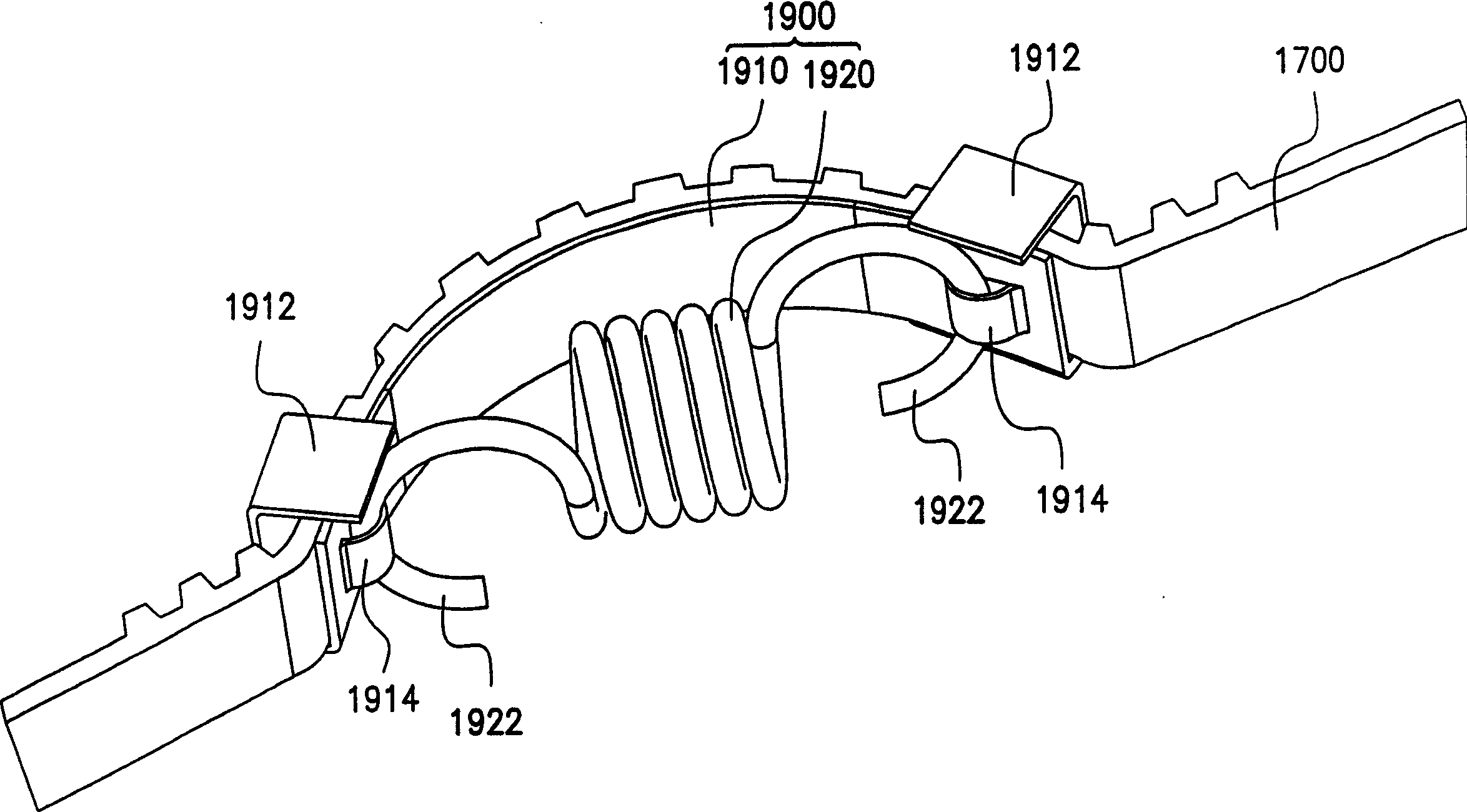

[0043]The present invention provides a belt tension adjusting device, by means of the elastic force of the belt tension adjusting device, the part of the transmission belt can be bent to maintain an appropriate tension, and the tension of the transmission belt can be easily adjusted, which is convenient for assembly Install and remove drive belts during assembly, maintenance or adjustment. The above-mentioned belt tension adjusting device can be realized by, for example, a leaf spring. By virtue of the elastic force of the plate spring, the part of the transmission belt is bent to maintain an appropriate tension, and the tension of the transmission belt can be easily adjusted to facilitate the installation or removal of the transmission belt during assembly, maintenance or adjustment. . And if in order to avoid elastic fatigue of the plate spring due to environmental or use factors, a tension spring, such as a tension coil spring, can be added to the above-mentioned belt tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com