Method for treating plant protein whey

A plant protein milk and processing method technology, applied in the field of plant protein concentrate production and comprehensive utilization, can solve the problems of increased acid or enzyme consumption, low alcohol recovery rate, decline and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

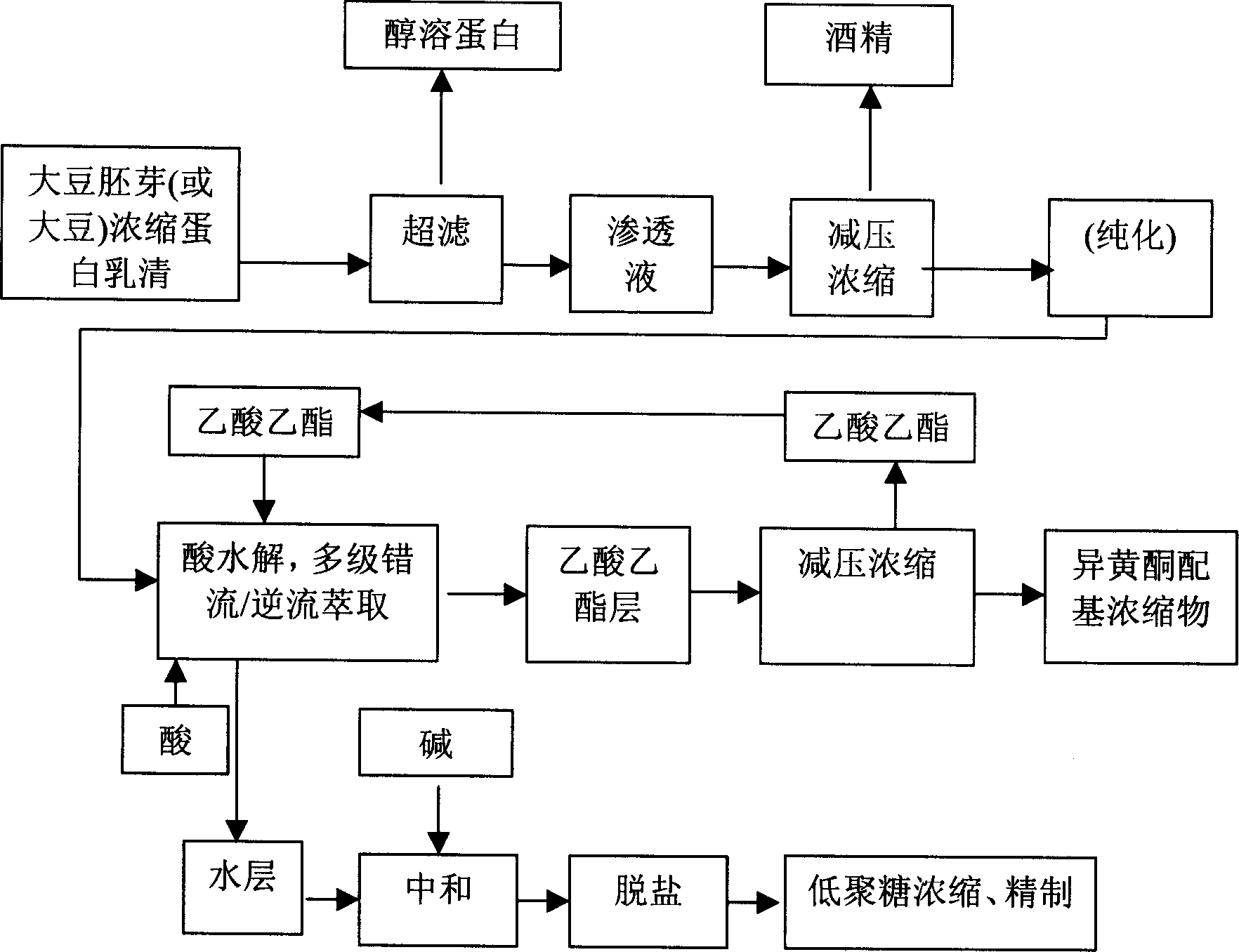

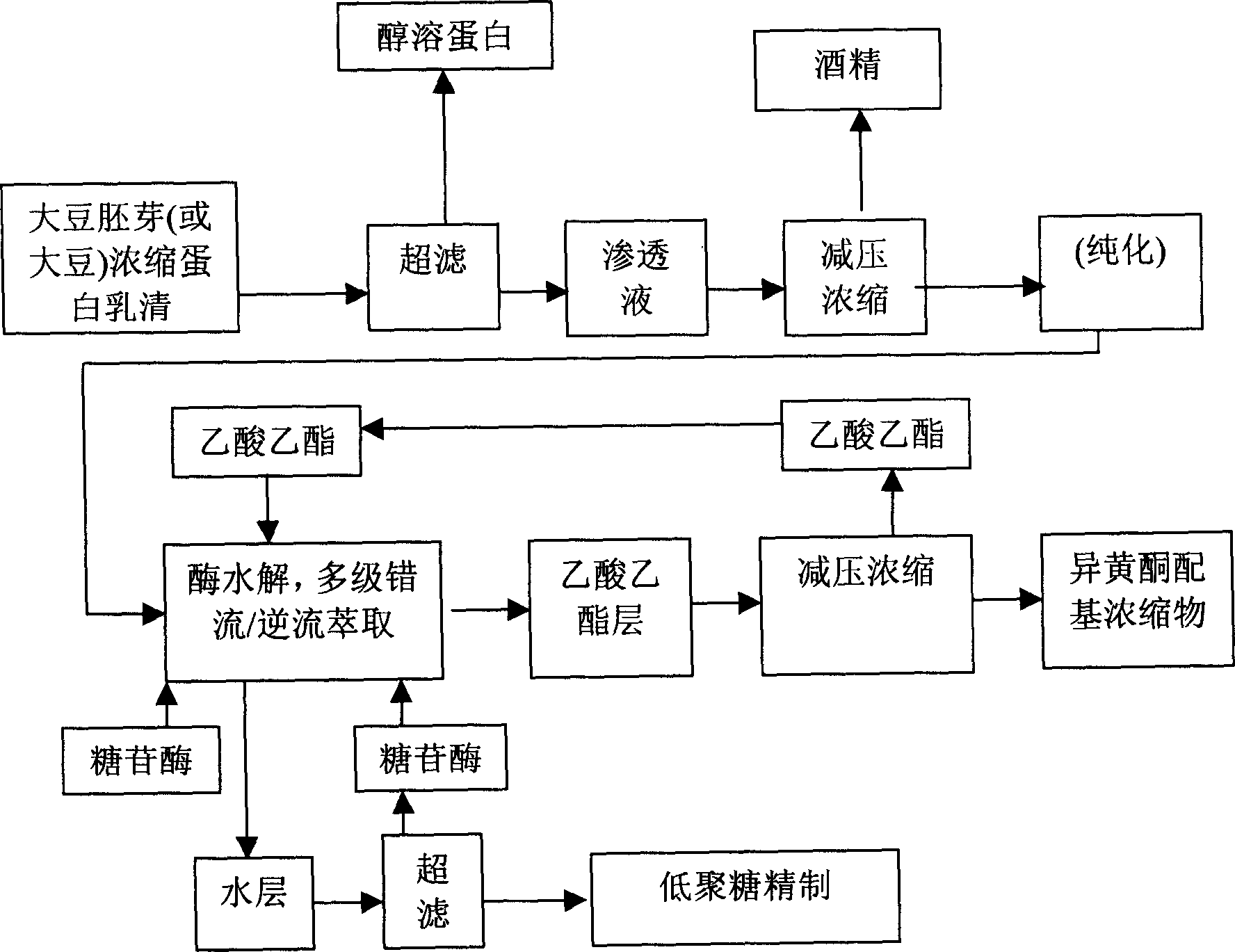

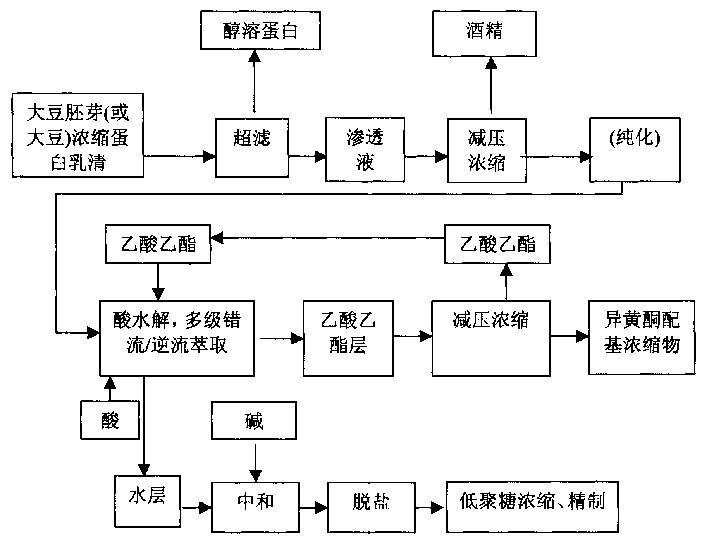

[0044] refer to figure 1 , which is a flowchart of acid hydrolysis dynamic cross-current / counter-current extraction in the present invention.

[0045] 1: First, the soybean (soybean germ) alcohol concentrated protein whey is subjected to ultrafiltration treatment, and the treatment method adopts an inorganic ceramic membrane with a molecular weight cut-off of 1000-20000 for ultrafiltration treatment.

[0046] Process conditions for ultrafiltration treatment:

[0047] Operating temperature: 5-60°C, inlet pressure: 0.3-0.8MPa, outlet pressure: 0.05-0.3MPa, flux 0.02-0.8m 3 / m 2 h,

[0048] After ultrafiltration treatment, gliadin and membrane permeate are obtained, gliadin can be recycled or processed separately, membrane permeate is concentrated under reduced pressure to recover alcohol, and the concentrate of permeate is obtained;

[0049] 2: The concentrate can be further purified by macroporous resin, solvent extraction and other methods to further purify isoflavones or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com