Apparatus and method for recovering marketable products from scrap rubber

A technology for waste rubber and substances, which can be used in charging devices, preparation of liquid hydrocarbon mixtures, coke ovens conveyed by mechanical devices, etc., and can solve problems such as difficulty in obtaining condensate compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

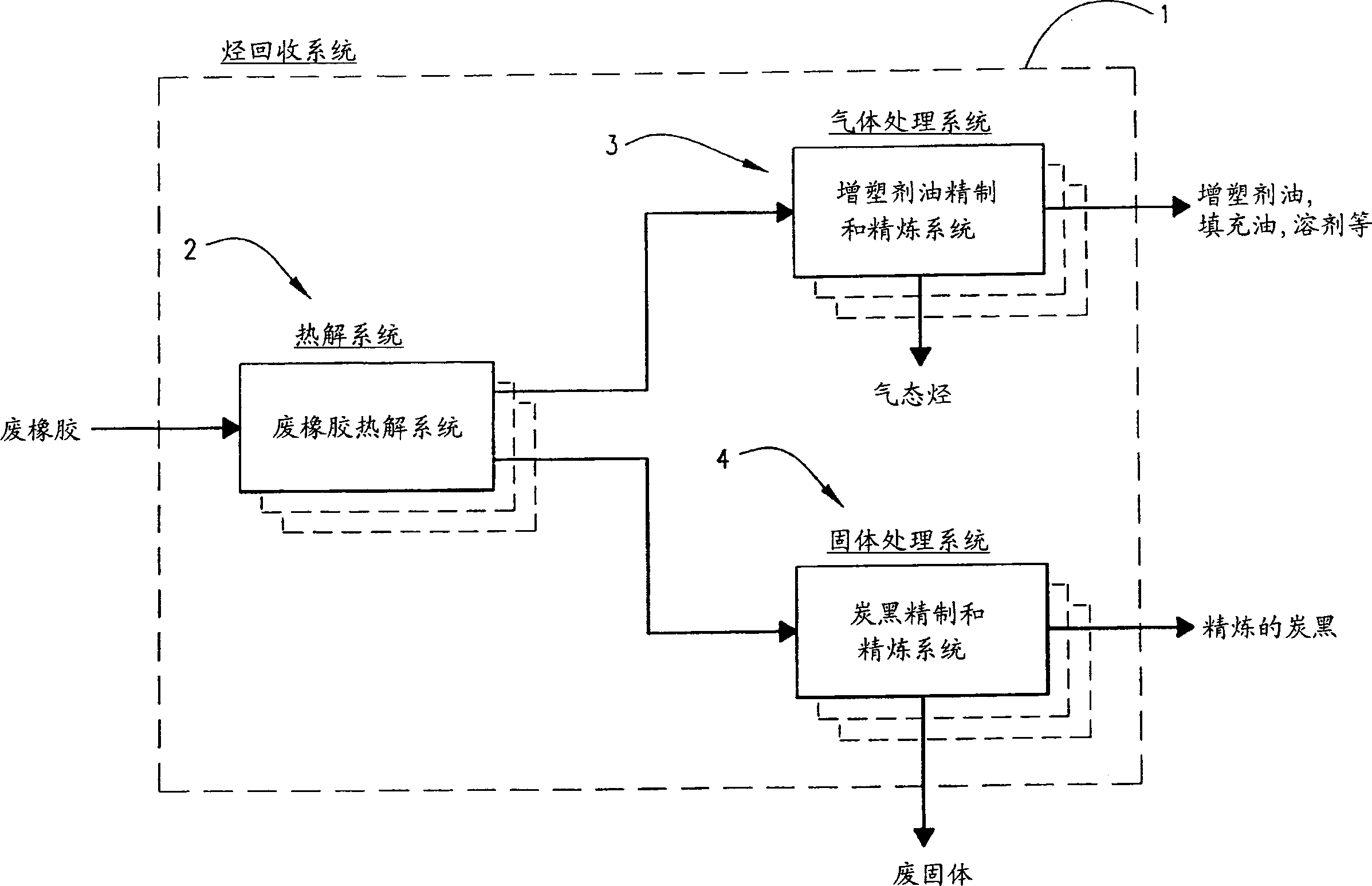

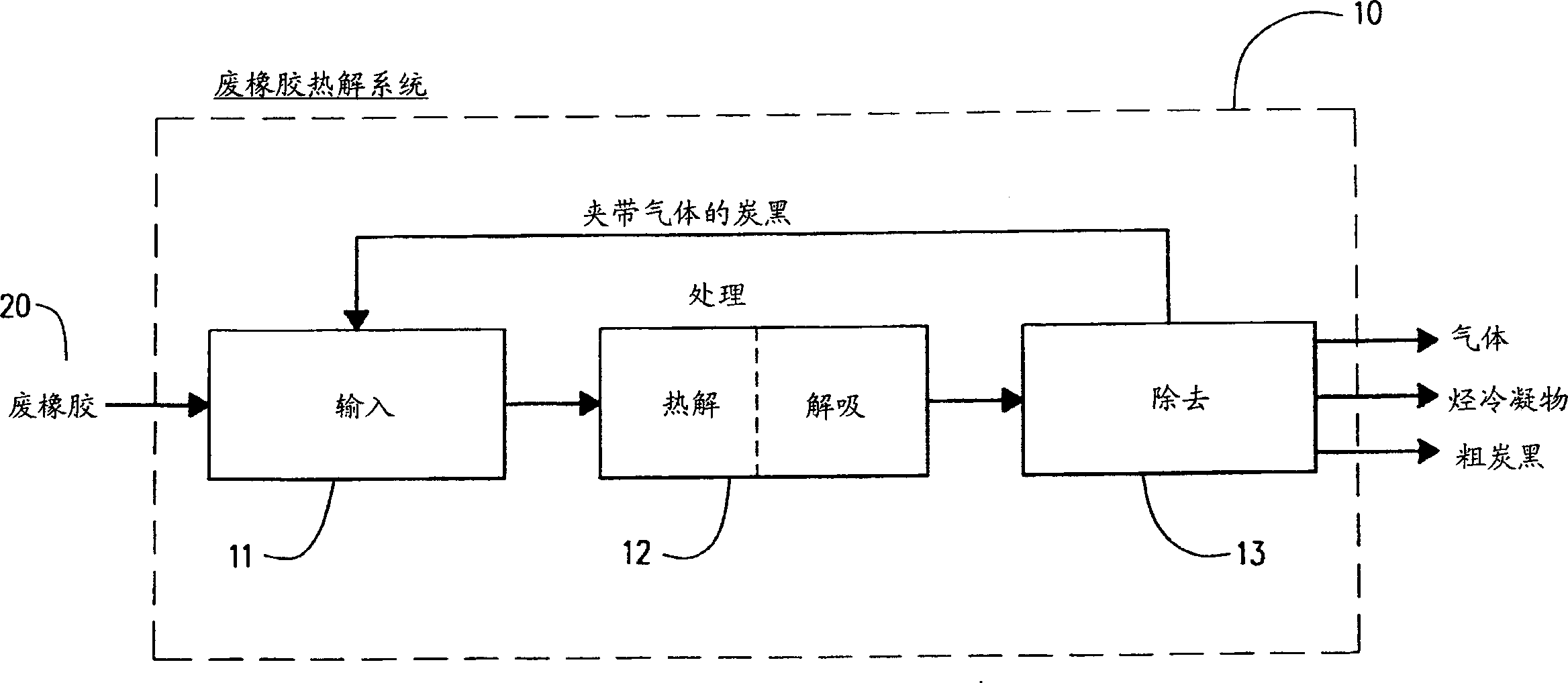

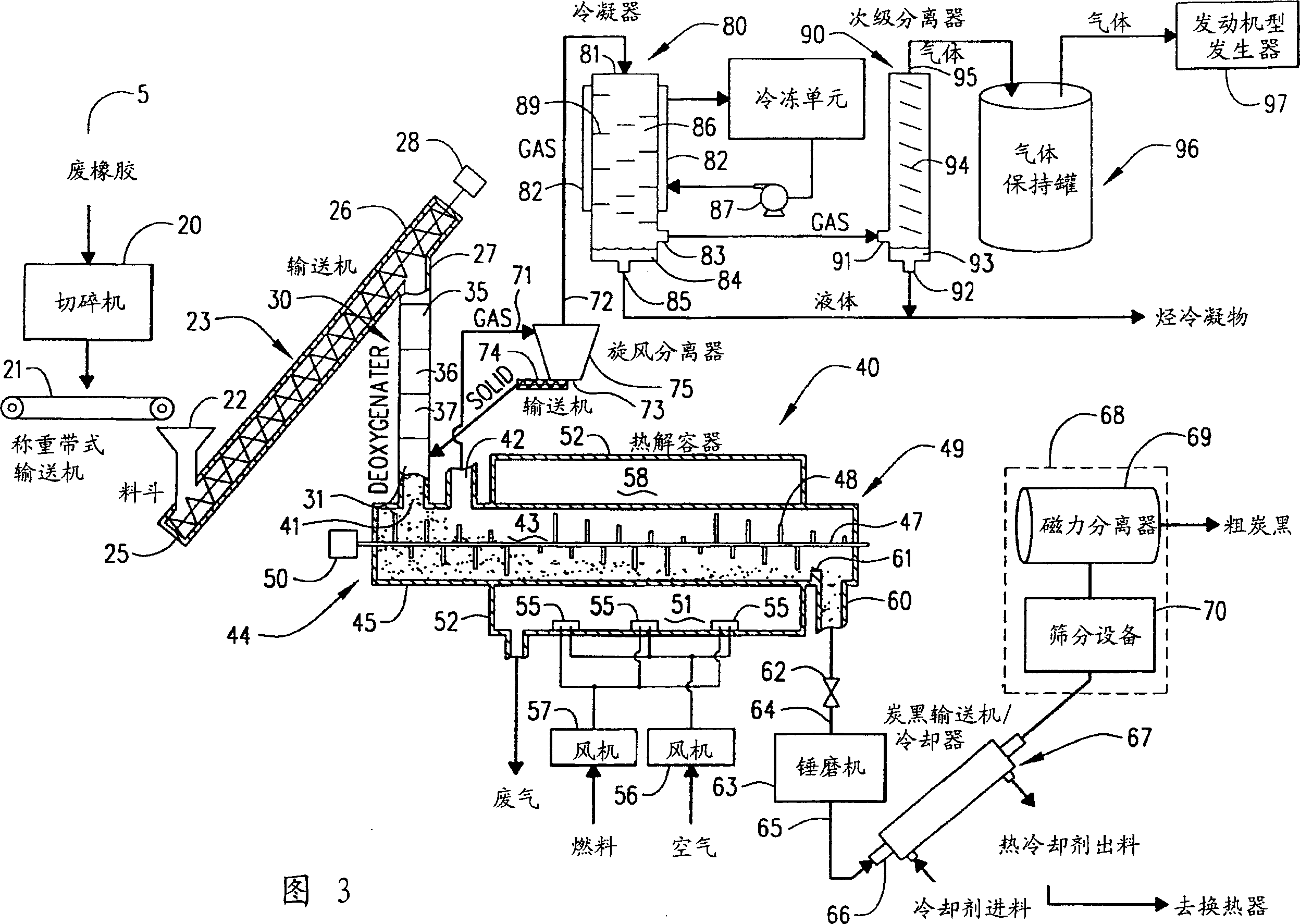

[0025] The present invention relates to a waste rubber recycling system for recovering a marketable end product from waste rubber. It consists of three subsystems. First, it includes a waste rubber pyrolysis system for breaking down tire shred raw material into its component parts, namely, pyrolysis gas composed of volatile hydrocarbons and granular carbon black containing inorganic impurities without adsorbing pyrolysis gas. The pyrolysis gas is provided substantially free of entrained carbon black particles and further broken down into selected hydrocarbon condensate fractions and vapor fractions. Second, it includes the carbon black refining and refining system, which further refines and refines granular carbon black to produce high-grade carbon black used in inks, rubber products, etc. Third, it includes the plasticizer oil refining and refining system, which further refines and refines the hydrocarbon condensate to produce high-grade plasticizer / extender oil, or "bright ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com