Method for manufacturing piezoelectric component

A technology of piezoelectric components and manufacturing methods, which is applied in the field of piezoelectric component manufacturing, can solve the problems of long time, large frequency changes of piezoelectric filters, large frequency changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

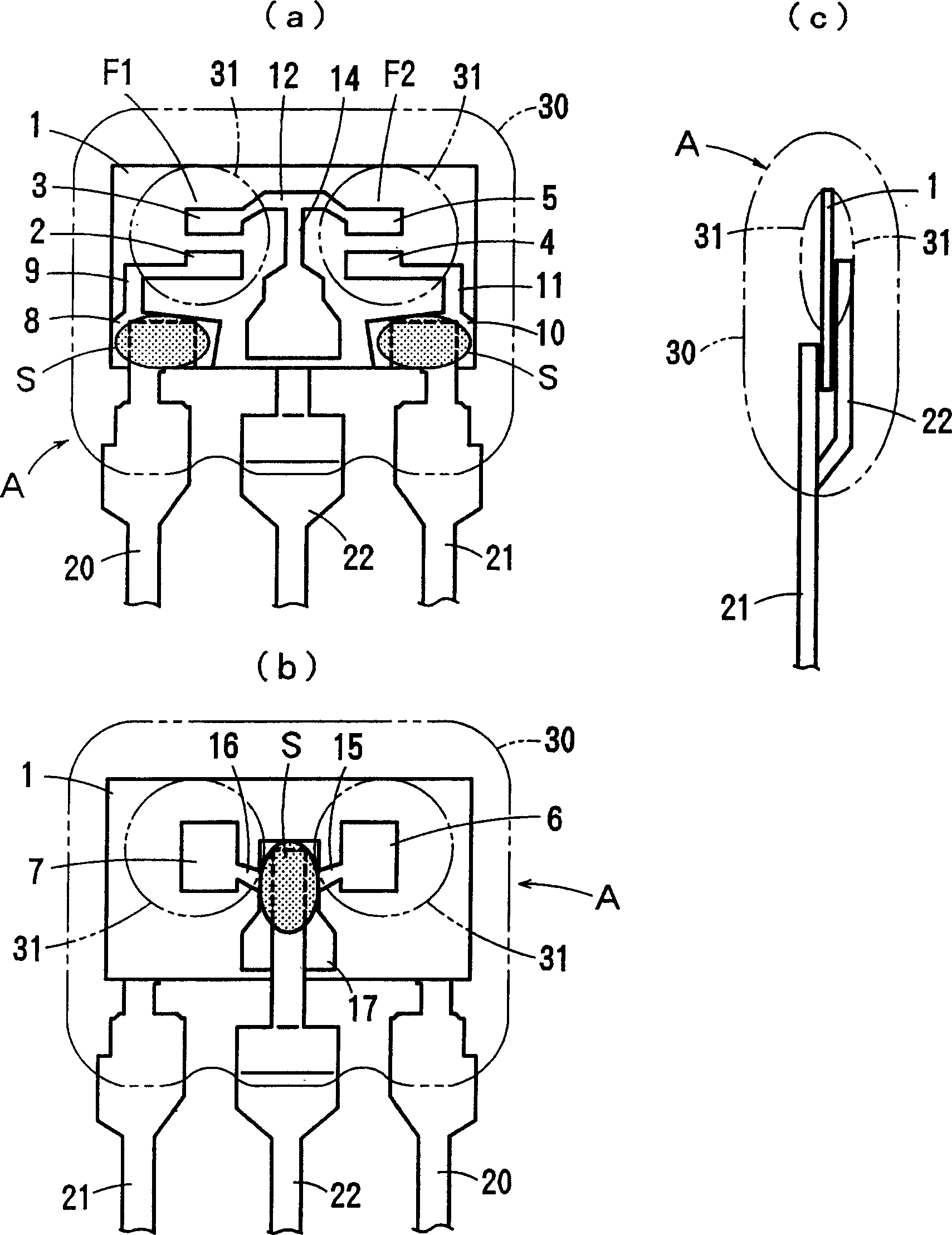

[0029] image 3 An example of a piezoelectric component manufactured by the manufacturing method of the present invention is shown. Here, an example of an energy-trapped piezoelectric filter utilizing thickness longitudinal vibration is shown.

[0030] Figure 4 is the circuit diagram of the above piezoelectric filter.

[0031] The piezoelectric filter A includes a piezoelectric element 1 made of rectangular plate-shaped piezoelectric ceramics or piezoelectric single crystal, and divided electrodes (vibration electrodes) 2, 3 and 4, 5, Counter electrodes (vibration electrodes) 6, 7 opposite to the divided electrodes 2, 3 and 4, 5 are formed in the inner main surface. Vibrating electrodes 2 , 3 , and 6 constitute one double-mode filter element F1 , and vibrating electrodes 4 , 5 , and 7 constitute the other double-mode filter element F2 .

[0032] On the outer main surface of the piezoelectric element 1, the split electrode 2 is connected to the input terminal electrode 8 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com