Microcapsulation heat absorbing particle

A micro-encapsulation and micro-encapsulation technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of influence, poor equipment, and shortening the life of heat-dissipating products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The heat-absorbing particle of the present invention is a microencapsulated microparticle with a core particle diameter of 1-1000 μm, the particle composition includes a shell and a core, and the shell is a compound selected from melamine formaldehyde, urea formaldehyde resin, PU, and acrylic high molecular polymer, the core is a heat-absorbing material selected from straight-chain alkanes, higher alcohols, and organic acids with a melting point of about 35°C-70°C, the weight of the shell and the core The ratio is about 1 / 20-1 / 2. In addition, dyes can be added to the core to become pigments with color and heat absorption, that is, the heat-absorbing particles in this article include or do not contain A general term for dyes, while heat-absorbing pigments refer to dyes.

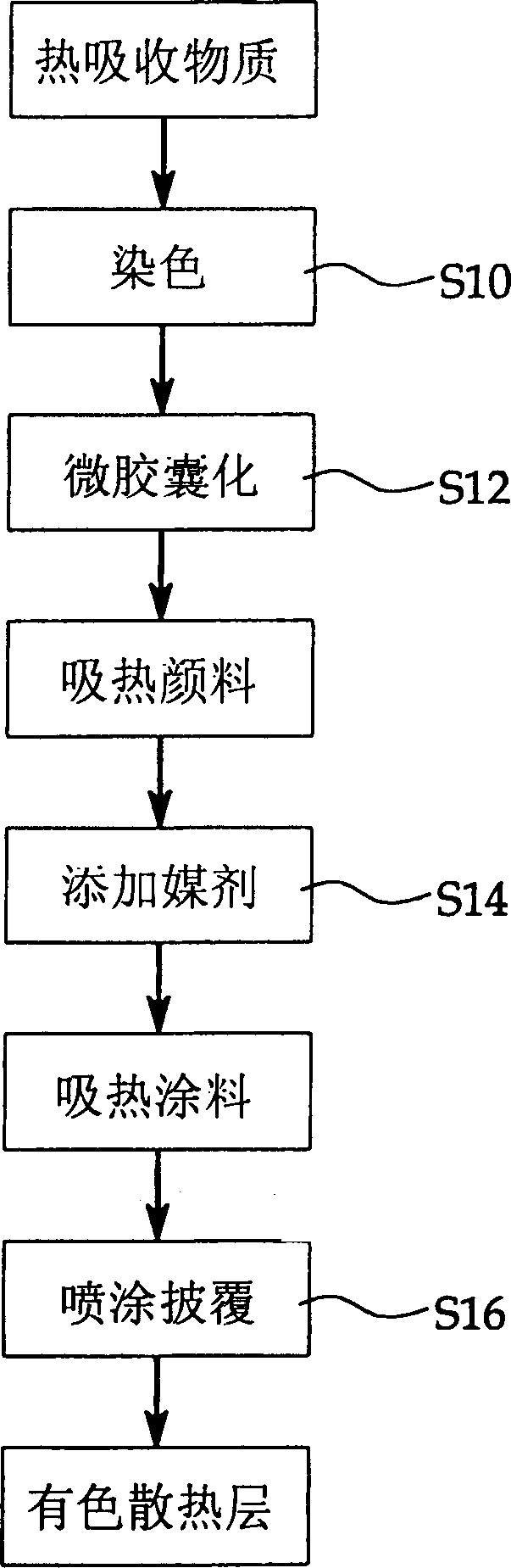

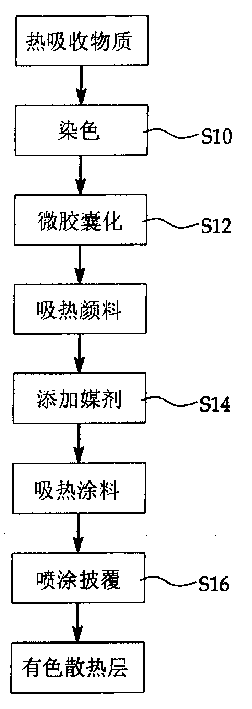

[0016] figure 1 Shown is the preparation and spraying method of heat-absorbing particles of the present invention, which mainly uses heat-absorbing substances that are easy to store and emit heat, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com