Plasma processing device and semiconductor mfg. device

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems of insufficient plasma excitation efficiency, inability to effectively stimulate plasma, and difficulty in plasma ignition, and achieve high plasma excitation efficiency and cooling efficiency Improved, high cooling efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0103] Figure 3A , Figure 3B A configuration diagram of a microwave plasma processing apparatus 10 according to a first embodiment of the present invention is shown.

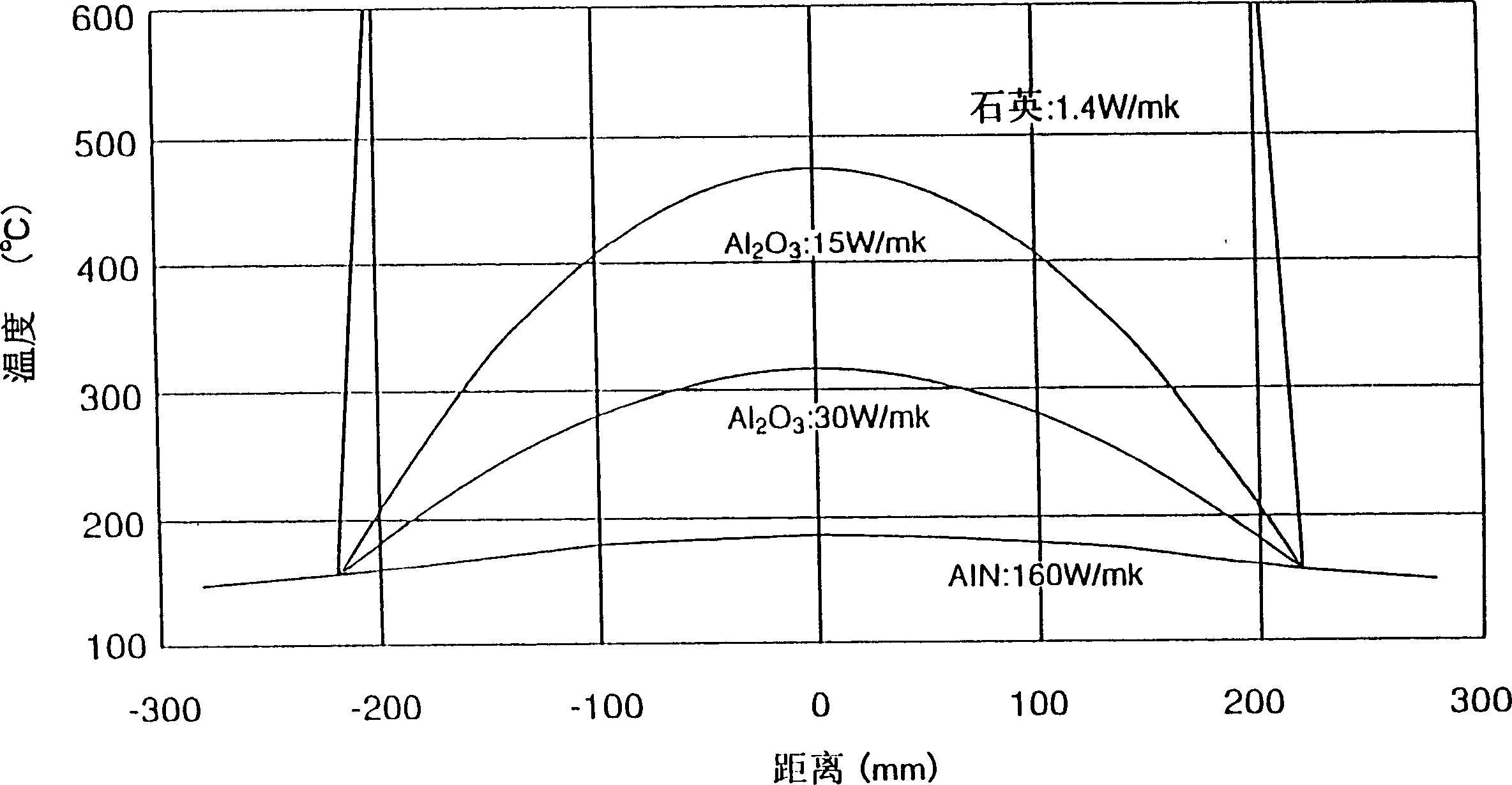

[0104] refer to Figure 3A , the aforementioned microwave plasma processing apparatus 10 includes a processing container 11 and an AlN or Al substrate 12 disposed in the aforementioned processing container 11 and held by an electrostatic chuck, preferably formed by hot isostatic pressing (HIP). 2 o 3 The holding table 13 constituted; in the space 11A surrounding the above-mentioned holding table 13 in the aforementioned processing container 11, at equal intervals, that is, with respect to the substrate 12 to be processed on the aforementioned holding table 13, it is generally in an axisymmetric relationship, at least two places, preferably Exhaust holes 11a are formed at three or more places. The aforementioned processing container 11 is exhausted and depressurized by screw pumps with unequal pitches and u...

no. 2 Embodiment

[0133] Figure 10 The configuration of a plasma processing apparatus 10A according to the second embodiment of the present invention is shown. However, in FIG. 1 , the same reference numerals are attached to the parts already described, and description thereof will be omitted.

[0134] refer to figure 2 , the plasma processing apparatus 10A has the same Figure 3A , Figure 3B The plasma processing apparatus 10 has a similar structure, however, the shower plate 14 is removed, and the gas introduction port 11p extending from the gas introduction hole 11p extends into the space 11B in the processing container 11.

[0135] Even in such a structure, high-density plasma can be formed in the space 11B by exciting the plasma gas introduced from the gas introduction port 11 p with the microwave supplied from the radiation slot antenna 20 .

[0136] The high-density plasma gas formed in this way is less uniform than the high-density plasma obtained when using the shower plate 14 ,...

no. 3 Embodiment

[0139] Figure 11 The configuration of a microwave plasma processing apparatus 10B according to the second embodiment of the present invention is shown. exist Figure 11 In , those parts that are the same as those already explained are denoted by the same reference symbols, and description thereof will be omitted.

[0140] refer to Figure 11 The microwave plasma processing apparatus 10B of the present embodiment has a structure similar to that of the microwave plasma processing apparatus of the foregoing embodiments, however, the foregoing processing gas supply structure 31 is eliminated in the microwave plasma processing apparatus 10B of the present embodiment. In addition, the extended portion 11b of the aforementioned processing container 11 is also formed in a circular shape on the lower side in order to avoid discharge.

[0141] In the plasma processing apparatus 10B of the above structure, microwaves are reflected by the plasma formed directly under the shower plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com