Organic field effect transistor

An organic field and transistor technology, applied in the field of organic field effect transistors, can solve problems such as non-solution and impractical, and achieve the effect of easy material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

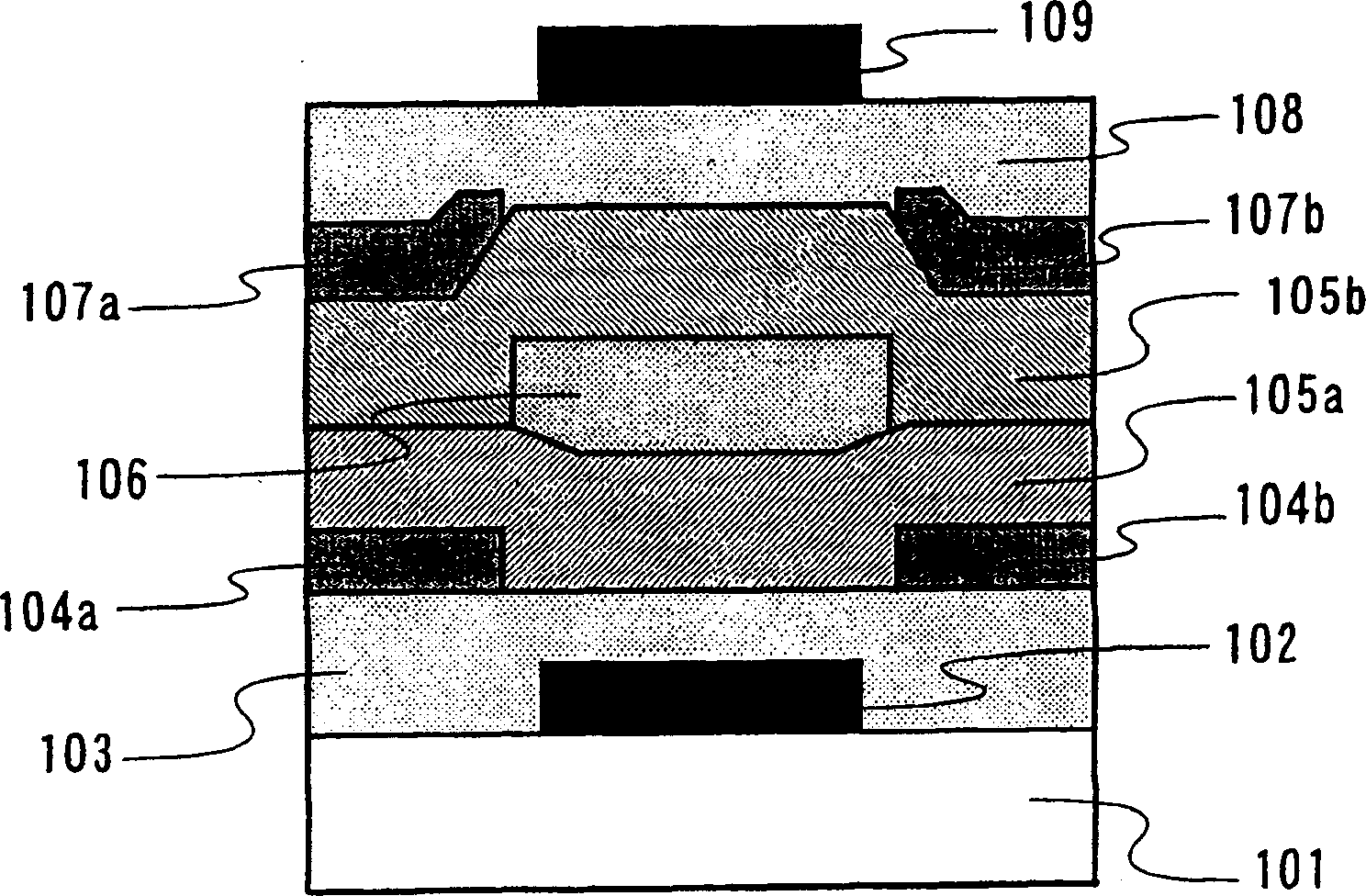

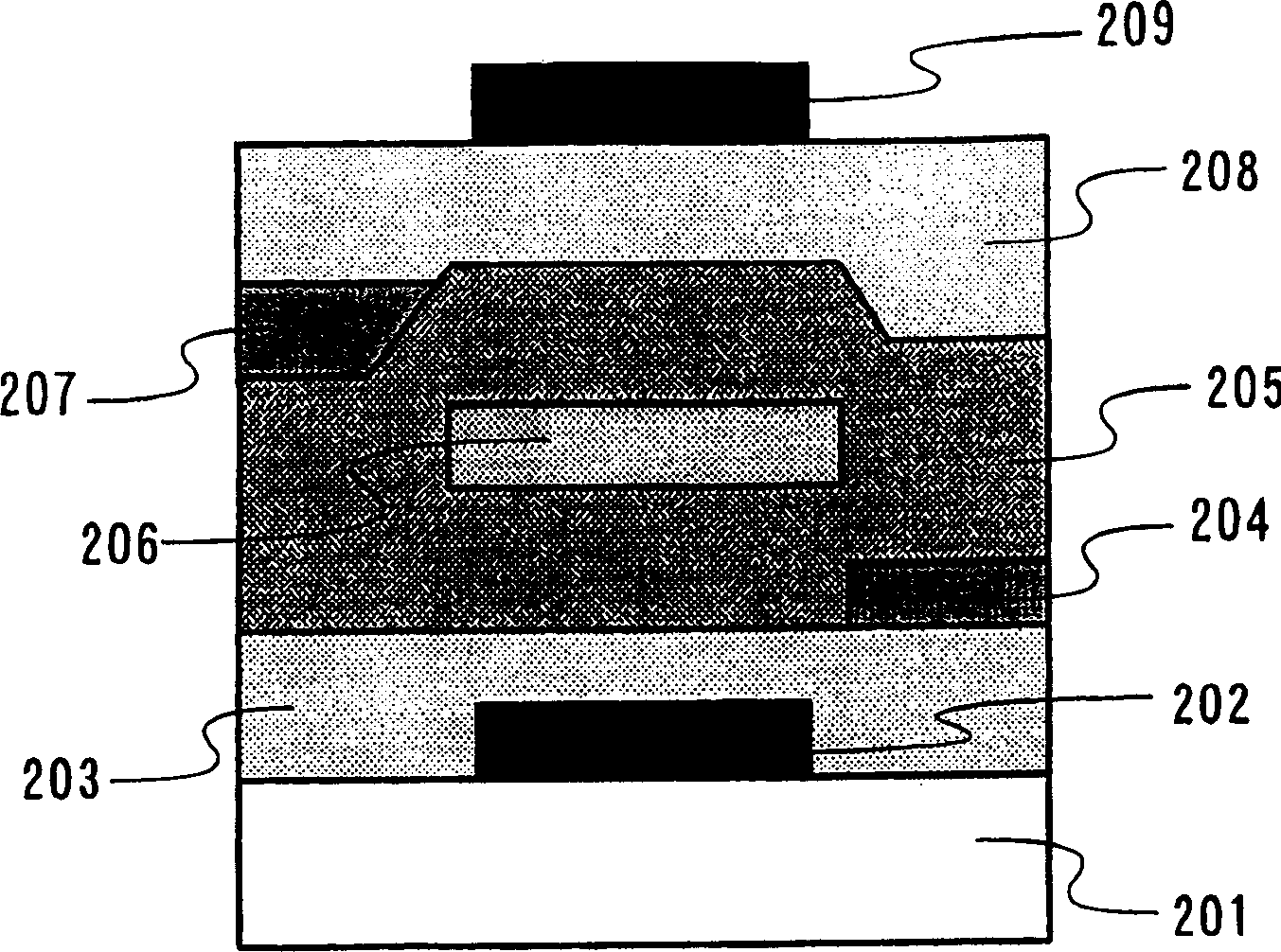

[0091] In this example, it will be specified Figure 1B The organic FET shown in . First, a 50 nm thick gold film was formed on a glass substrate by vacuum evaporation through a mask having a first gate electrode pattern. Thus, a first gate electrode having a length of 500 μm on each side was formed.

[0092] Move the glass substrate to a chemical evaporation device. Xylylene Dimer (xylylene dimer) (product name: parylene, parylene manufactured by Parylene Japan) was heated under reduced pressure, and a heating tube heated to 680° C. was inserted for pyrosis. Therefore, radicals were generated Monomer. The generated radical monomer was introduced onto the substrate kept at room temperature to form a 300 nm thick polyparaxylylene film. This is the first gate insulating film.

[0093] Next, in order to form the first source electrode and the first drain electrode, a mask pattern was provided so that the length of the source-drain was 50 μm. Thus, a 50 nm-thick gold thin film...

example 2

[0101] In this example, the specific Figure 1B The organic FET shown in . First, a 50 nm thick gold film was formed on a glass substrate by vacuum evaporation through a mask having a first gate electrode pattern. Thus, a first gate electrode having a length of 500 μm on each side was formed.

[0102] Move the glass substrate to a chemical evaporation device. Xylylene Dimer (xylylene dimer) (product name: parylene, parylene manufactured by Parylene Japan) was heated under reduced pressure, and a heating tube heated to 680° C. was inserted for burning. Thus, a radical monomer was generated. The generated radical monomer was introduced onto the substrate kept at room temperature to form a 300 nm thick polyparaxylylene film. This is the first gate insulating film.

[0103] Next, in order to form the first source electrode and the first drain electrode, a mask pattern was provided so that the length of the source-drain could be 50 μm. Thus, a 50 nm-thick gold thin film was for...

example 3

[0111] In this example, it will be specified Figure 1B The organic FET shown in . First, a 50 nm thick gold film was formed on a glass substrate by vacuum evaporation through a mask having a first gate electrode pattern. Thus, a first gate electrode having a length of 500 μm on each side was formed.

[0112] Move the glass substrate to a chemical evaporation device. Xylylene Dimer (xylylene dimer) (product name: parylene, parylene manufactured by Parylene Japan) was heated and evaporated under reduced pressure, and a heating tube heated to 680° C. was inserted for burning. Thus, a radical monomer was generated .The generated free radical monomer is introduced onto the substrate kept at room temperature to form a 300nm thick polyparaxylylene film. This is the first gate insulating film.

[0113] Next, in order to form the first source electrode and the first drain electrode, a mask pattern was provided so that the length of the source-drain could be 50 μm. Thus, a 50 nm-thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com