Stirrer used in makeup production

A blender and cosmetics technology, which is applied to blender accessories, mixers with rotating stirring devices, mixers, etc., can solve the problems of low efficiency, good stirring effect, complicated process, etc., and achieve convenient operation, sufficient stirring, and stirring uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

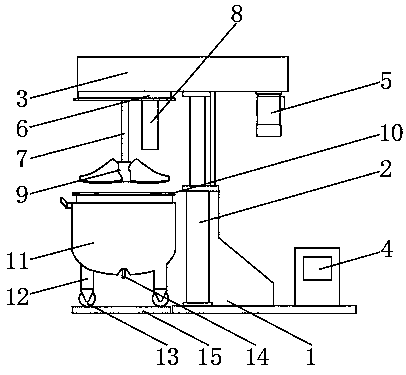

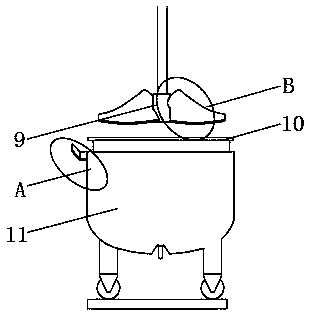

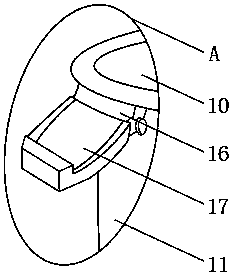

[0020] Such as Figure 1-4 As shown, a mixer for cosmetics production includes a main body base 1, a lifting rod 2 and a crossbeam 3, the main body base 1 is located on the bottom outer surface of the lifting rod 2, the crossbeam 3 is located on the upper end outer surface of the lifting rod 2, and the main body base 1 is provided with a control box 4 on one side of the outer surface, a motor 5 is provided on the lower end outer surface of one side of the beam 3, and a stirring container upper cover 6 is arranged on the other lower end outer surface of the beam 3, and the center of the lower end of the stirring container upper cover 6 The outer surface is provided with a stirring spindle 7, and one side of the stirring spindle 7 is provided with a water spray column 8. The water spray column 8 can directly add water to the raw material, or clean the blade and the stirring container 11, and the water spray column 8 is located in the stirring container. The outer surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com