Hydrogen-producing fuel rod, preparation method thereof, and hydrogen generator based on hydrogen-producing fuel rod

A generator and hydrogen fuel technology, applied in electrochemical generators, fuel cells, chemical instruments and methods, etc., can solve the leakage of alkaline metal borohydride aqueous solution, the incomplete reaction of sodium borohydride, and the easy carrying of strong alkali solutions Leakage and other problems can be achieved to achieve the effect of fuel utilization, convenient source, and improved hydrogen storage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the hydrogen-producing fuel rod of the present invention comprises the following steps:

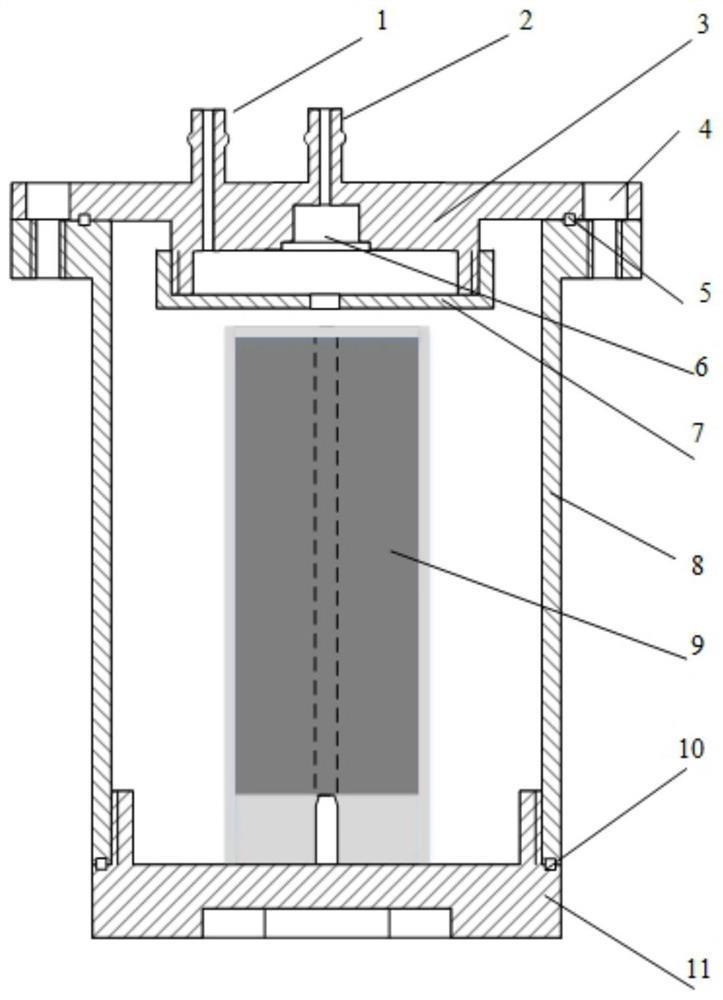

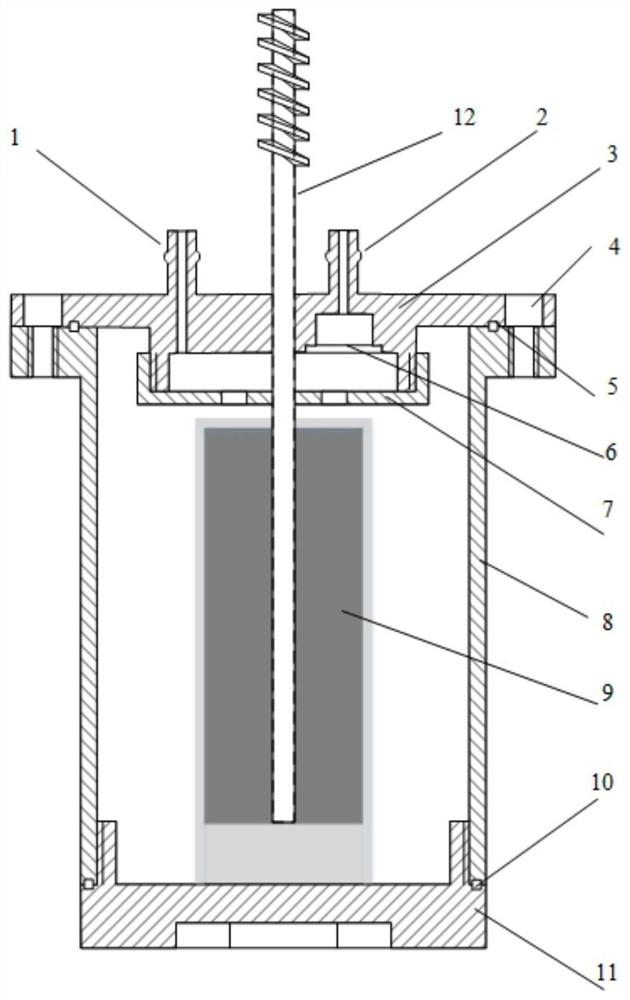

[0036] Prepare porous medium cloth 2A by hydrophilic porous medium material, then soak porous medium cloth 2A in acid solution, dry and lay flat, and mix solid alkaline metal borohydride and catalyst at the same time to obtain fuel powder 2B, spread the fuel powder evenly on the porous medium cloth 2A, and then roll it so that the surface of the porous medium cloth 2A absorbs a layer of fuel powder 2B, and then use the cylinder as the core to absorb the fuel powder 2B. The porous medium cloth 2A is wound into a cylindrical hydrogen-producing fuel rod 9 , and finally the winding core is pulled out to obtain a hydrogen-producing fuel rod 9 .

Embodiment 2

[0038] The preparation method of the hydrogen-producing fuel rod of the present invention comprises the following steps: soaking the hydrophilic porous medium material in an acid solution, drying it, mixing it with a catalyst and a solid basic metal borohydride, and then using a press to pass it through a mold The mixture is pressed into hollow cylindrical hydrogen-producing fuel rods 9 .

Embodiment 3

[0040] The preparation method of the hydrogen-producing fuel rod of the present invention comprises the following steps: making the hydrophilic porous medium material into a plurality of circular cloths which are successively empty, soaking them in an acid solution and then drying them; The borohydride is mixed to obtain fuel powder 2B, and then the fuel powder 2B is pressed into a number of cylindrical sheets with uniform thickness and a through hole in the middle, and then the cylindrical sheets are inserted between two adjacent layers of circular cloth, Produce hydrogen fuel rod 9.

[0041] Specifically, the specific production process of the fuel powder 2B in each embodiment is as follows: ball milling the solid alkaline metal borohydride and the catalyst, then pulverizing the solid alkaline metal borohydride and the catalyst particles and mixing them uniformly, Fuel powder 2B was obtained, and the acid solution in each embodiment was malic acid solution or citric acid sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com