Capacity forecast and ordering sheet data exchange system and method

A technology of production capacity forecasting and exchange system, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems that cannot be grasped and controlled in advance, and cannot be determined in advance, and achieves a smooth effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

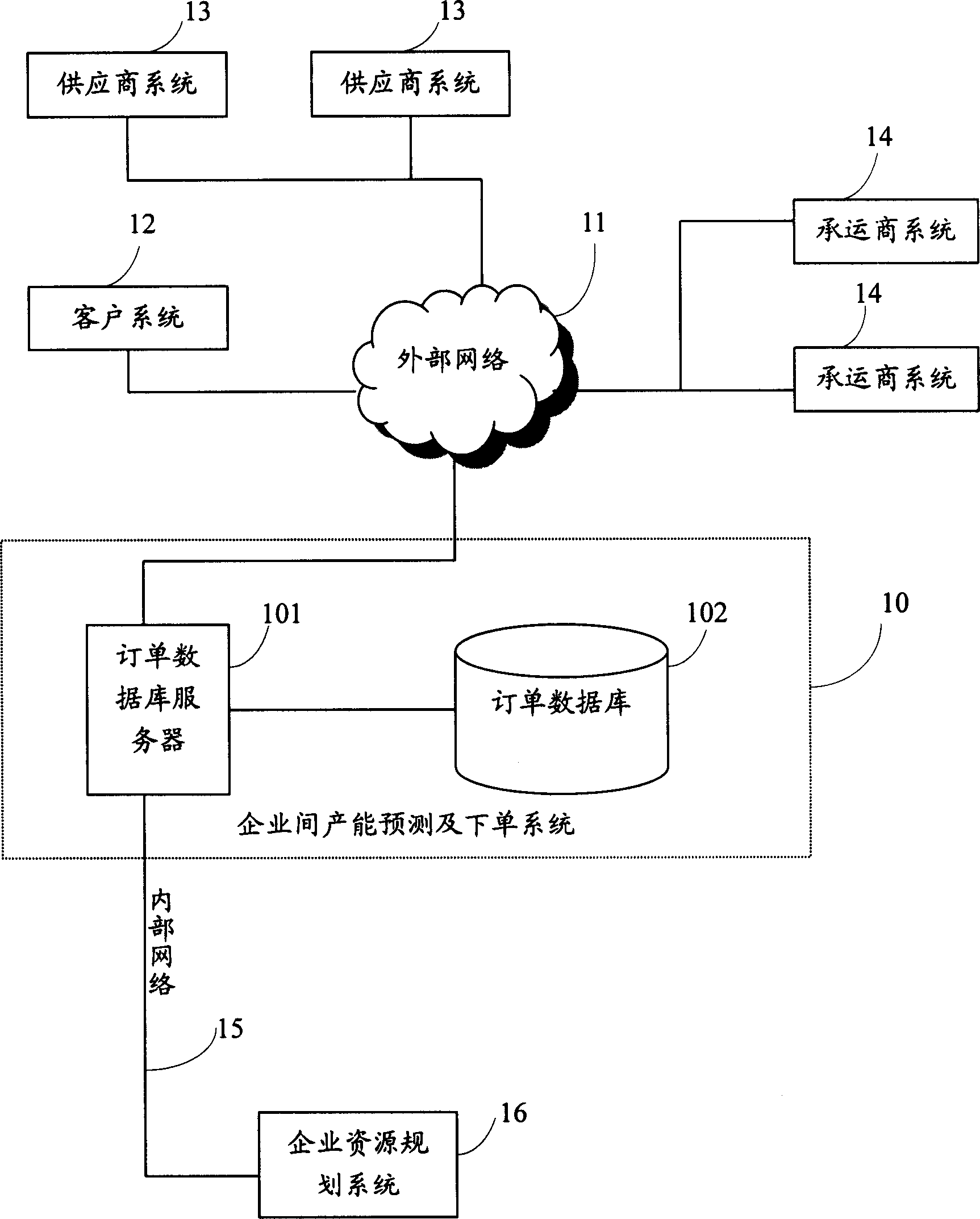

[0017] Such as figure 1 Shown is a hardware structure diagram of the production capacity forecasting and order data exchange system among enterprise systems of the present invention. The production capacity prediction and order data exchange system 10 between enterprise systems is composed of an order database server 101 and an order database 102 . The system 10 is connected with a customer system 12, a plurality of supplier systems 13 and a plurality of carrier systems 14 through an external network 11 (in this embodiment, the external network 11 can be the Internet or a private network Extranet, etc.), and through the internal network 15 (in the present invention, the network 15 may be a local area network LAN within the enterprise) is connected with an enterprise resource planning system 16 to obtain production capacity forecast and order-related information. The order database server 101 sequentially integrates the obtained production capacity forecast data (not shown) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com