Vortex compressor

A scroll compressor, scroll technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problems of increased sliding loss, increased number of parts, decreased production efficiency, etc., to achieve mechanical efficiency The effect of improving, increasing the number of parts, and improving the efficiency of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

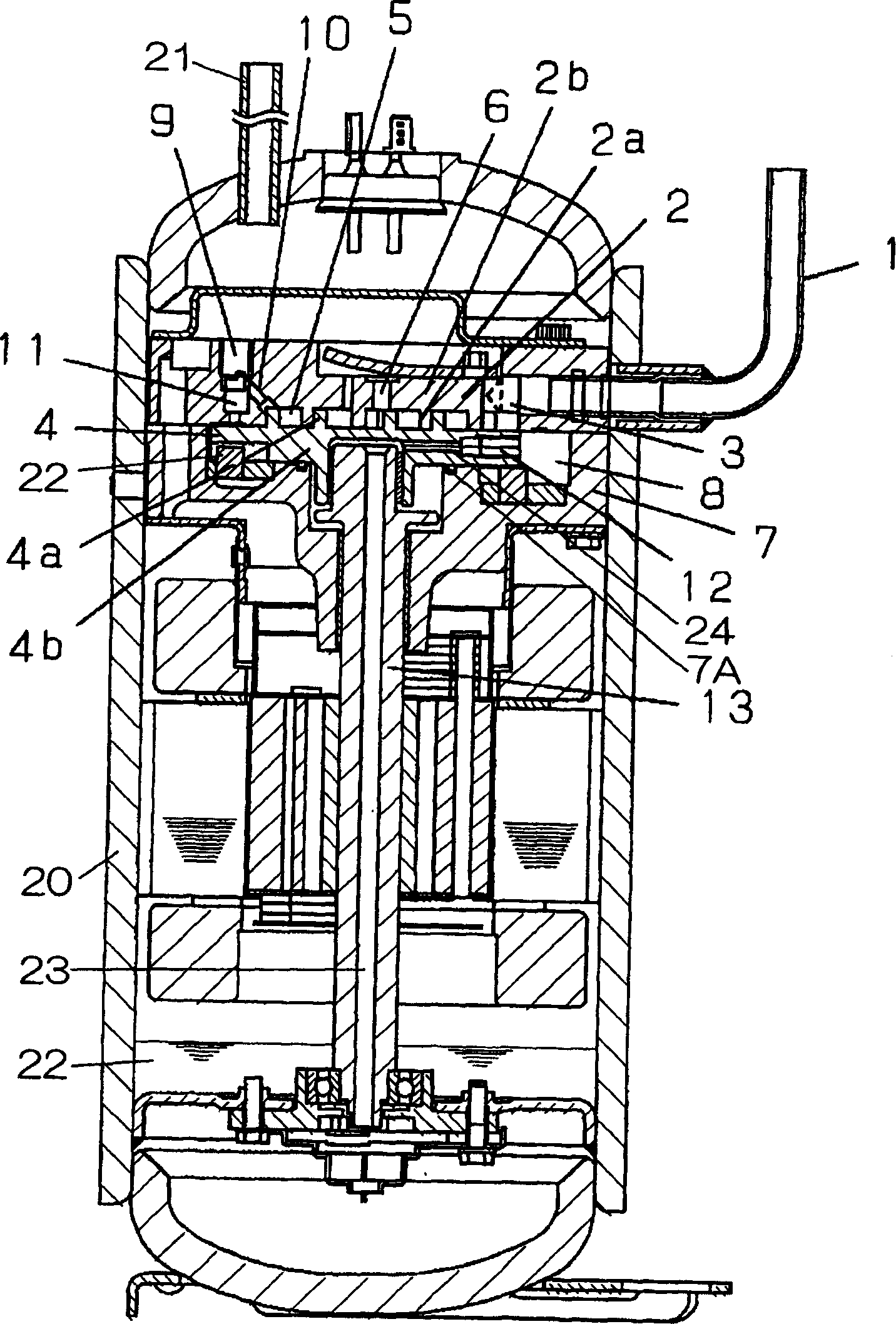

[0034] figure 1 The scroll compressor of the first embodiment is shown.

[0035] The scroll compressor has a compression mechanism part and a motor mechanism part in the airtight container 20 . The compression mechanism unit is disposed above the airtight container 20 , and the motor mechanism unit is disposed below the compression mechanism unit. A suction pipe 1 and a discharge pipe 21 are provided on the upper portion of the airtight container 20 . An oil storage portion 22 for storing lubricating oil is provided at a lower portion inside the airtight container 20 .

[0036] In the compression mechanism part, the fixed scroll 2 and the orbiting scroll 4 form a compression chamber 5 composed of a plurality of compression spaces. The fixed scroll member 2 is constituted by erecting a wrap 2a from an end plate 2b, and the orbiting scroll member 4 is constituted by erecting a wrap 4a from an end plate 4b. The compression chamber 5 is formed by engaging the wrap 2a and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com