Three phase AC permanent magnet synchronous motor

A permanent magnet synchronous, three-phase AC technology, applied in synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as motor soft start, Achieve the effect of reducing induced current, good starting performance, and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

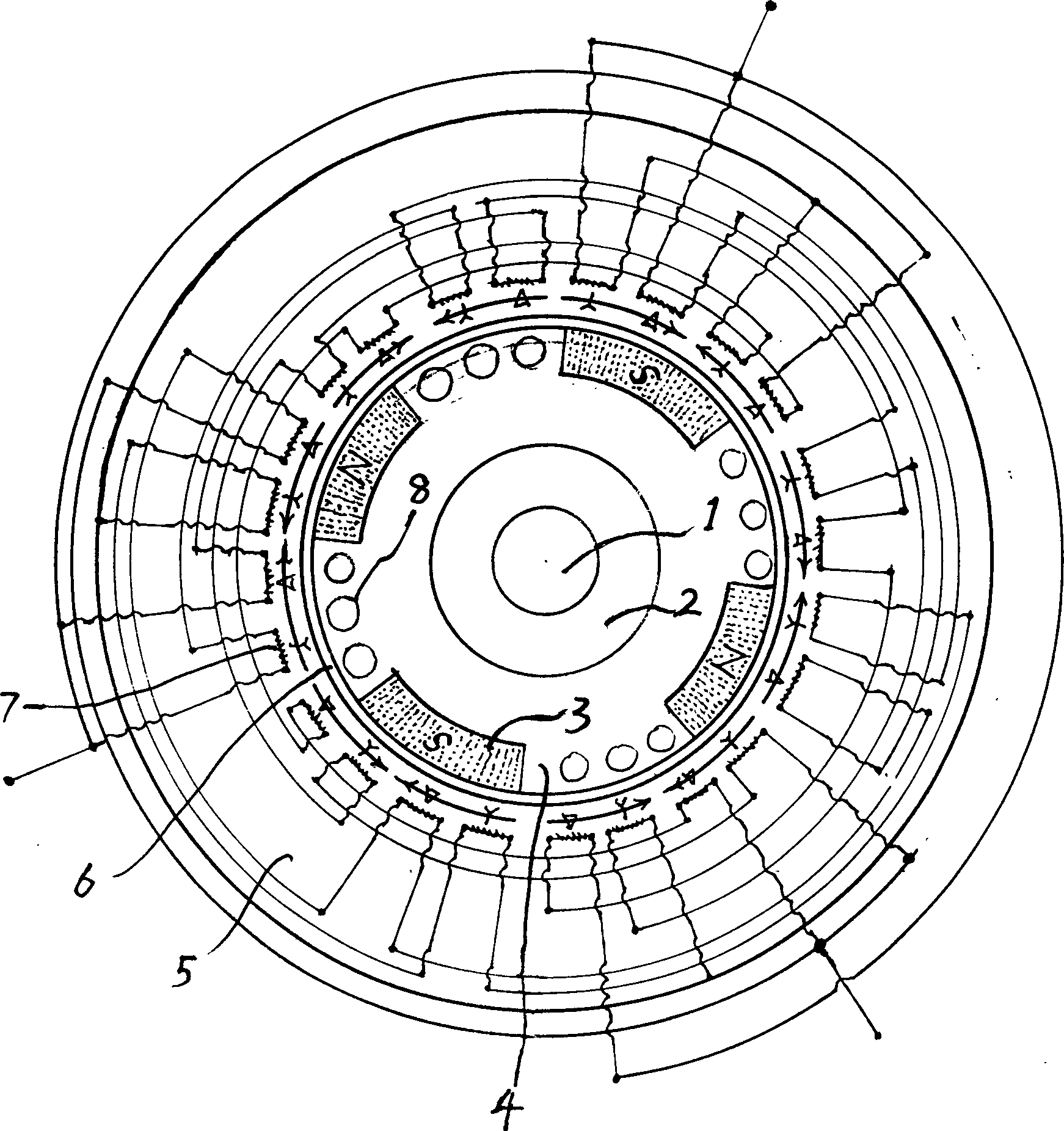

[0020] figure 1 In , a wiring method of a three-phase sinusoidal winding with each pole phase arranged in an extended-delta or star-delta arrangement is given. The phase potentials of the three-phase sinusoidal windings are different from each other by an electrical angle of 120°. exist figure 1 An embodiment of the rotor is also given in , the rotor electromagnet is a quadrupole, and is arranged on the surface of the rotor, that is, embedded in the surface structure. The conductive metal strips are parallel to the axial direction of the rotor and are embedded in the outer layer of the rotor.

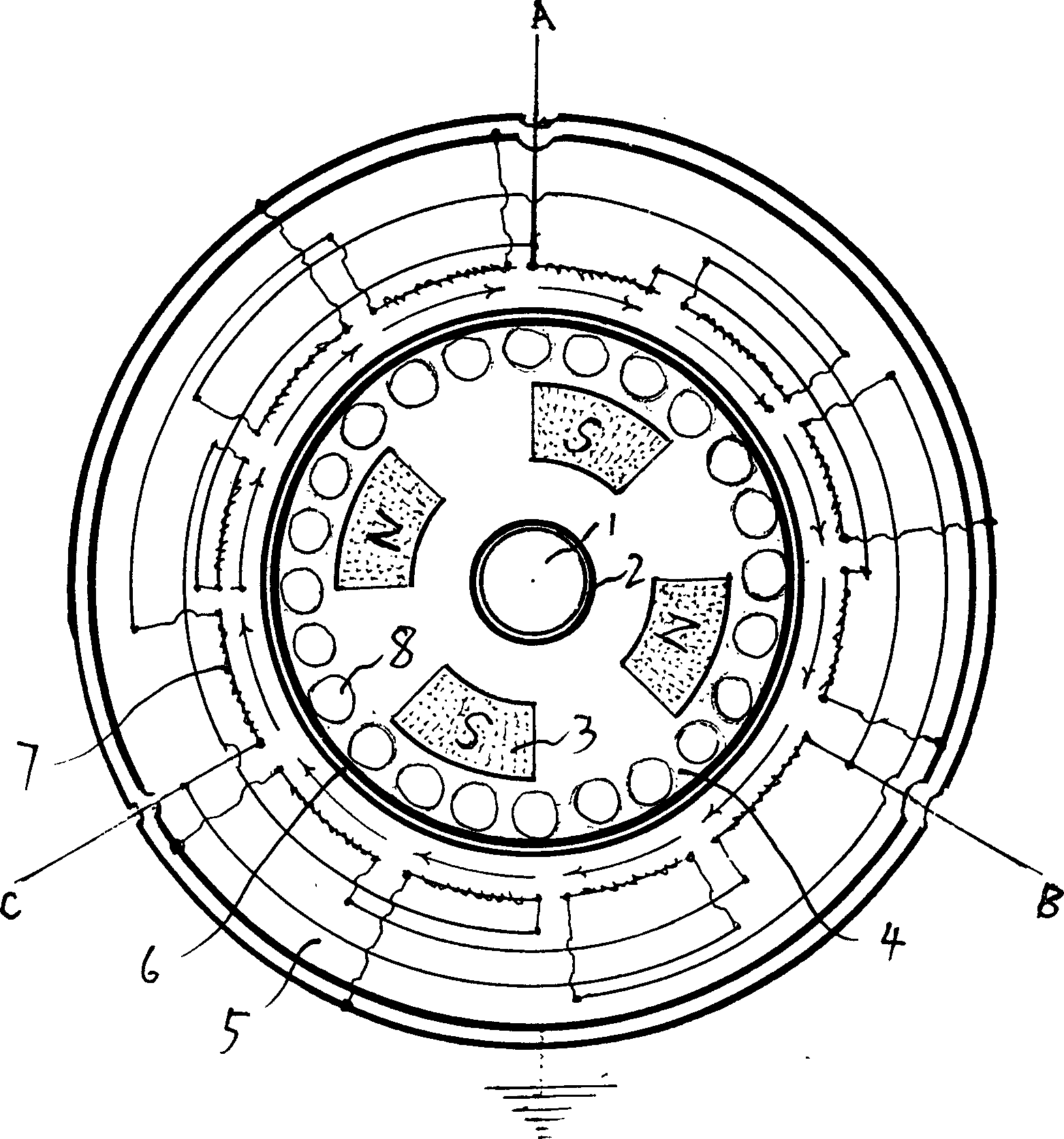

[0021] figure 2 , gives the same figure 1 Basically the same implementation, the only difference is that figure 1 are arranged in stars and angles in a polar phase group, figure 2 There are both star windings and angle windings in each slot of a pole phase group.

[0022] image 3 In , the schematic diagram of the three-phase winding of the stator according to the two-plane con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com