Current-limiting armoured heating cable and element

An armored heating cable and heating element technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of limited use, poor life and reliability, large power consumption of aircraft, etc., to reduce power loss, improve working life and Reliability, fast heating and effect of automatic adjustment of heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1: Heating Cable

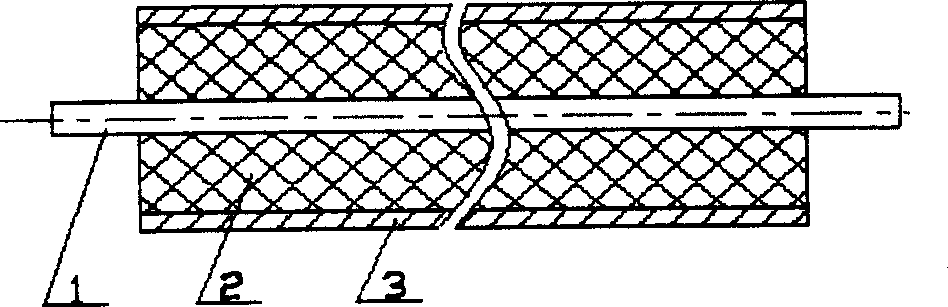

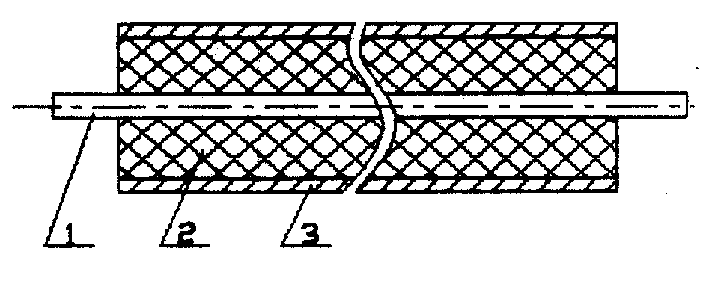

[0011] The chemical composition of the nickel-iron-based alloy heating wire is 70% Ni, 30% Fe. After vacuum smelting, thermal processing, cold processing and heat treatment, it is prepared into an alloy wire with a certain diameter, and it is combined with a metal sleeve (In.600, Stainless steel or pure nickel) and magnesium oxide insulating material are assembled into a metal armored cable blank, which is made into a current-limiting armored heating cable with a sleeve diameter of φ1.2mm after thermal processing, cold processing and heat treatment, and a core wire diameter of φ0.25mm , the room temperature unit resistance value is 3.3Ω / m, and its structure is as follows figure 1 , 1 is heating wire, 2 is magnesia insulating material, 3 is alloy casing, and its properties are shown in Table 1.

Embodiment 2

[0012] Example 2: Heating Cable

[0013] The composition, process and structure of the alloy heating core wire and heating cable are the same as in Example 1. The armored heating cable blank is processed by heat and cold deformation and heat treatment to prepare an armored heating cable with a diameter of φ1.0mm, and the diameter of the core wire is about φ0. 20mm, the room temperature unit resistance is 7.5Ω / m.

Embodiment 3

[0014] Example 3: Heating Element

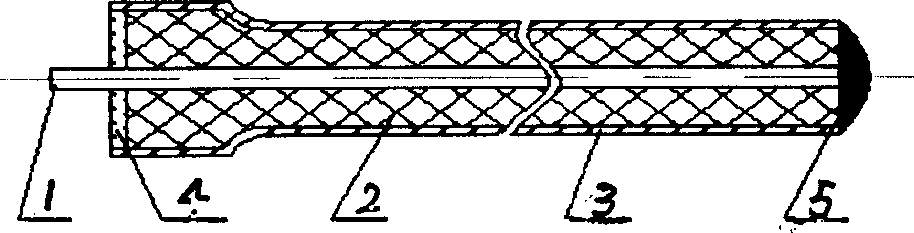

[0015] The composition of the alloy core wire and the heating cable is the same as in Example 1, and the formation of the element is to use one end of the armored heating cable as the working end, process the diameter reduction to φ0.7×1000mm, and weld the core wire and the sleeve at the working end connected to form a conductive circuit. The other end of the cable is the lead end, that is, the cold end. The lead wire and the sleeve of this end are sealed with insulating material, and the structure is as follows: figure 2 , 1 is heating wire, 2 is magnesia insulating material, 3 is alloy casing, 4 is working end solder joint, 5 is lead end. The room temperature resistance of the heating element is 9Ω, and the performance is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com