Coating forming method, apparatus and device, method for mfg. device and electronic apparatus

一种涂层、设备的技术,应用在涂层形成设备领域,能够解决设备质量下降等问题,达到好连续性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below.

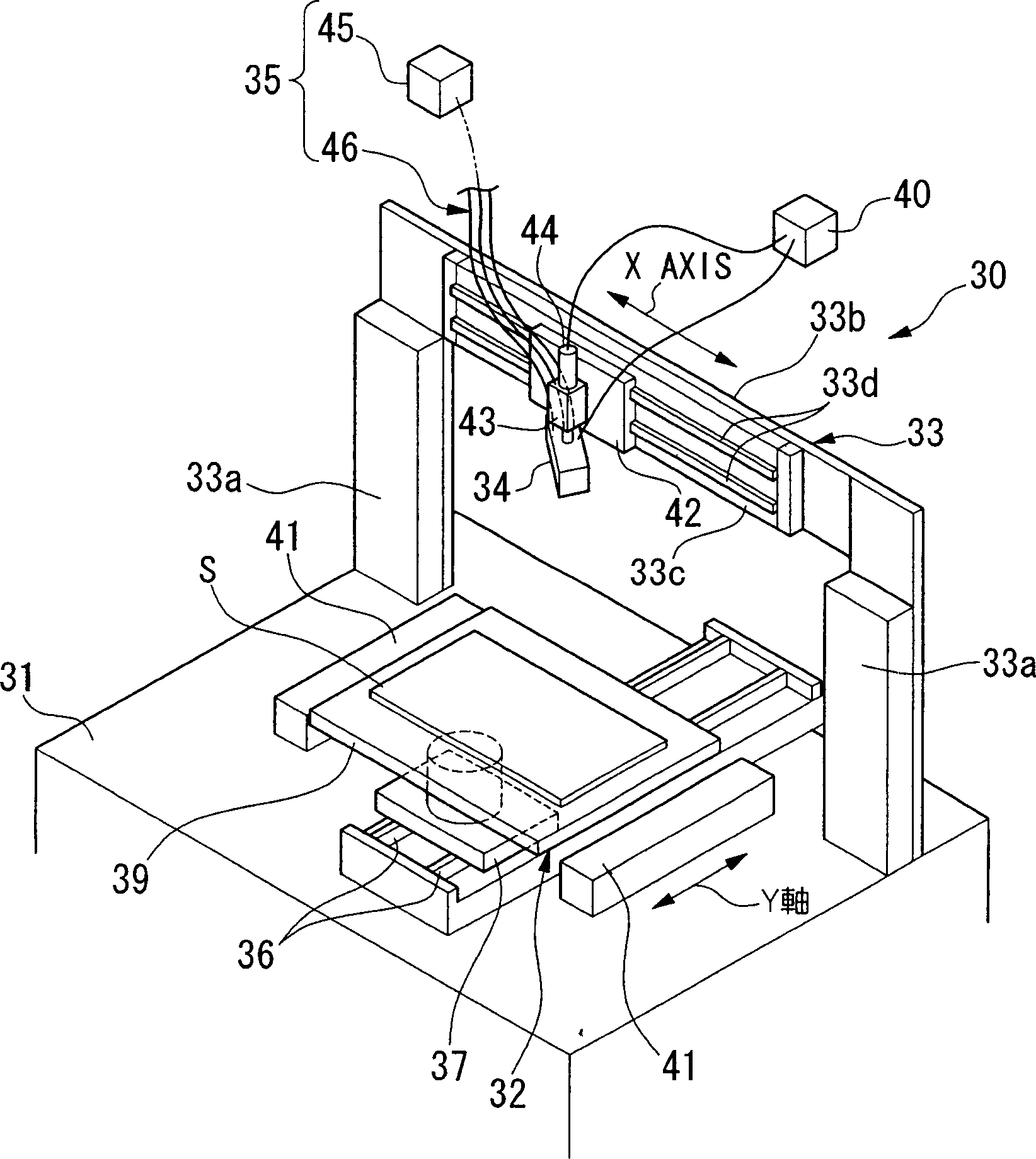

[0040] figure 1 An example of a coating forming apparatus according to the present invention is shown. figure 1Reference numeral 30 denotes a coating forming apparatus. The coating forming apparatus 30 is configured with a base 31, a motherboard operating part 32, a head moving part 33, a liquid drop discharge head 34, a liquid supply part 35, a control part 40, and the like. Both the motherboard operating part 32 and the head moving part 33 are mounted on the base 31 . The motherboard handling part 32 is mounted on the base 31 . The motherboard operating unit 32 is equipped with a guide rail 36 arranged along the Y-axis direction. The motherboard operating part 32 can move the slider 37 along the guide rail 36 by, for example, a linear motor (not shown in the figure).

[0041] The platform 39 is fixed on the slider 37 . The motherboard S is placed on the platform 39 and kept at a predetermined position. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com