Cooling medium engine apparatus

A technology of engines and refrigerants, applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as reuse, excessive heat, and pollute the environment, so as to prevent heat waste, solve environmental pollution, and achieve great social and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

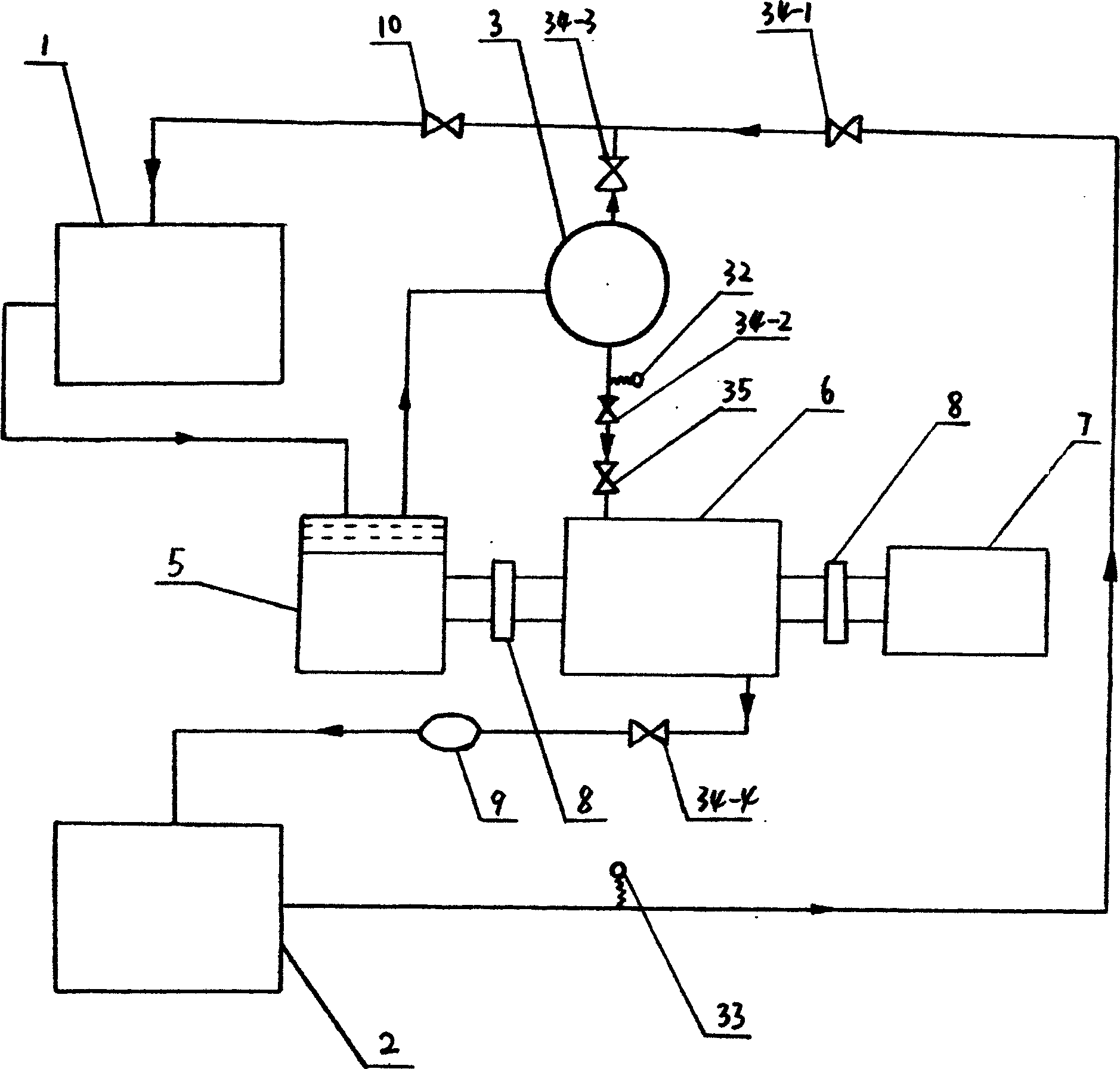

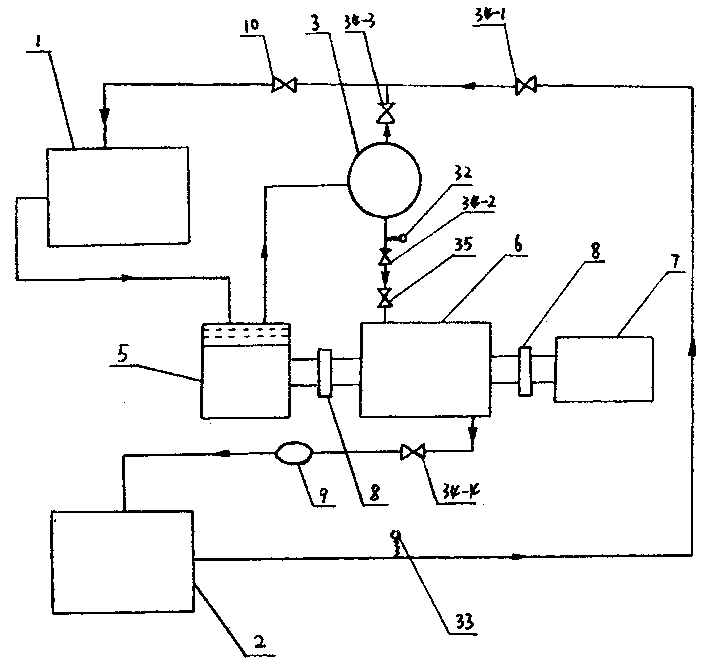

[0017] Such as figure 1 As shown, each device constitutes a closed loop system. According to the requirements of ordinary refrigeration technology, press and evacuate. After the refrigerant is quantitatively filled, the starter 7 starts, and the starter drives the refrigeration compressor 5 through the coupling 8, and the refrigeration compression Machine 5 starts to push the system to circulate, at the same time solenoid valves F1 (34-1) and F4 (34-4) are opened, solenoid valves F2 (34-2) and F3 (34-3) are closed, and the refrigerant liquid passes through solenoid valve F1 (34-4). -1), F4 (34-4) flows to the decompression device 10, after decompression, it flows into the evaporator 1 in a mist shape, and the refrigerant starts to absorb heat through the evaporator. The refrigerant enters the refrigeration compressor 5 from the initial subcooled low-pressure steam (fog), and is compressed by the refrigeration compressor 5 to become high-pressure superheated steam and sent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com