Gas turbine generating system and flow by cooling liquefied natural gas to separate carbon dioxide

A liquefied natural gas and carbon dioxide technology, applied in gas turbine installations, machines/engines, mechanical equipment, etc., can solve problems such as system efficiency decline, insufficient LNG cold utilization, consumption, etc. System simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

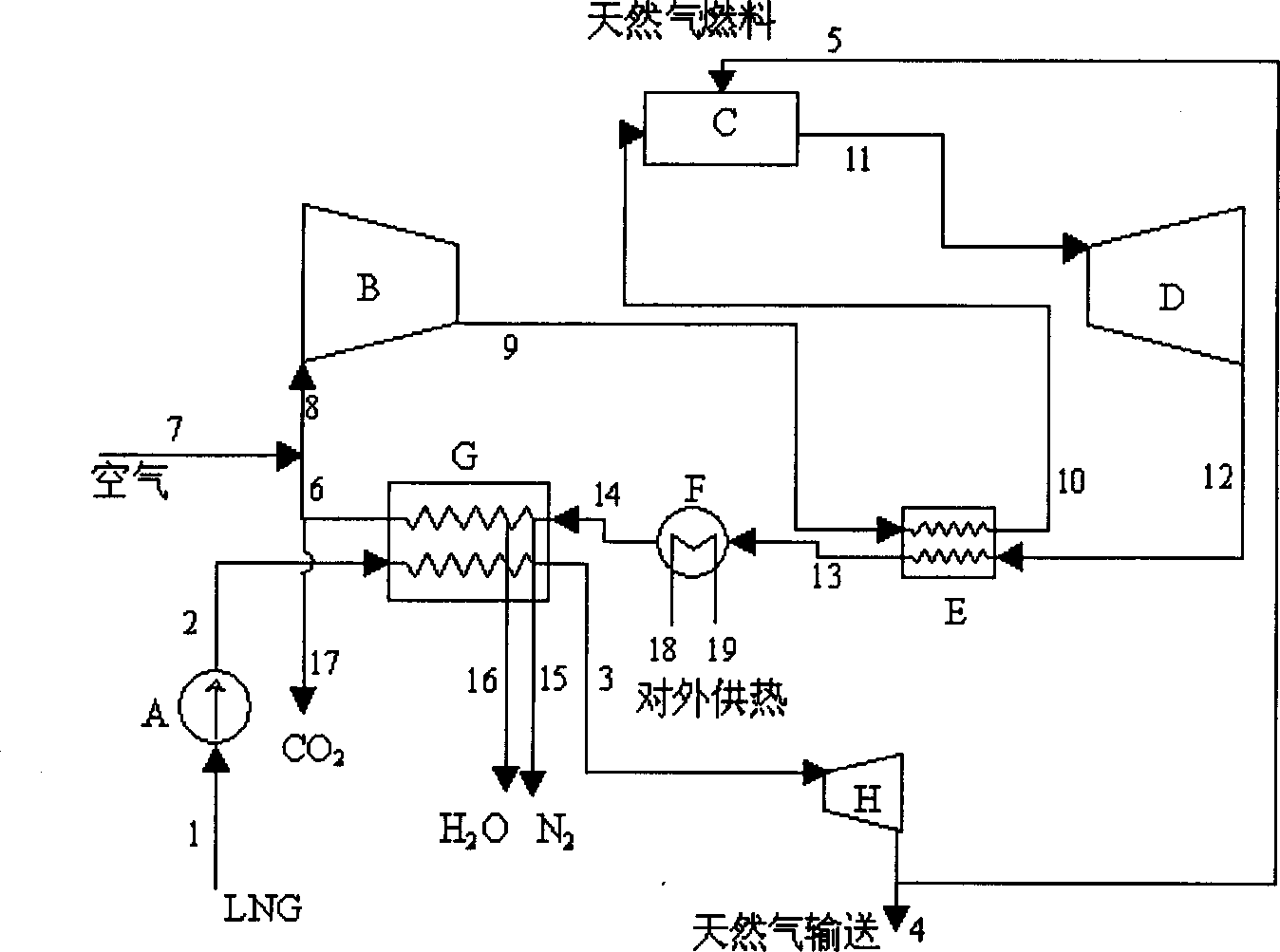

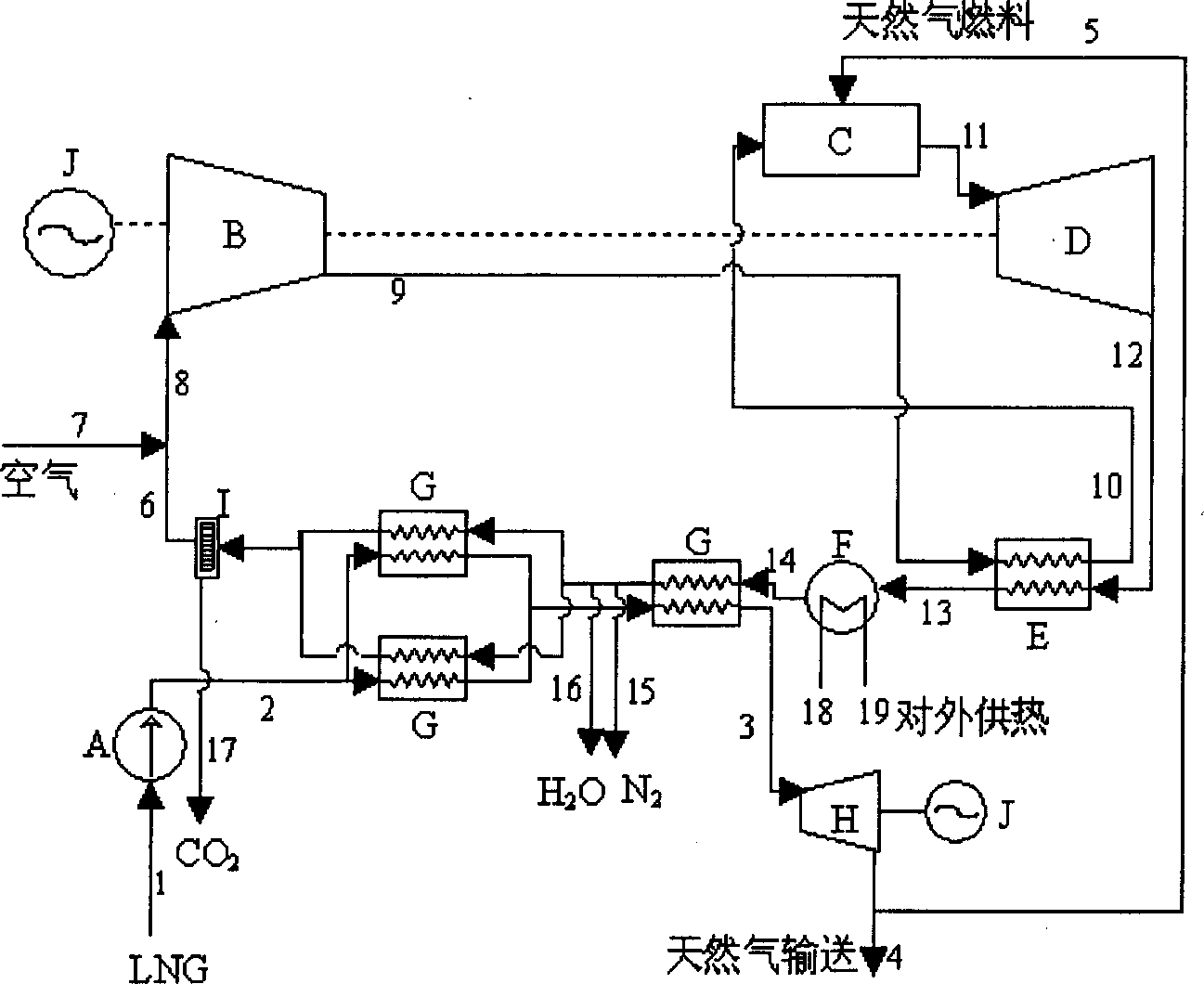

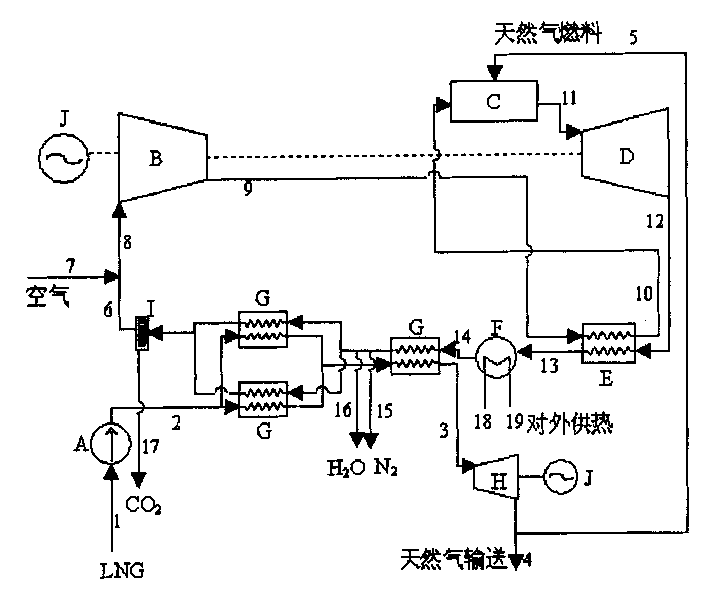

[0063] Please see figure 1 and figure 2 , the main parts of the present invention are semi-closed, regenerative gas turbine circulation system and LNG gasification system, in this system: A-LNG booster pump; B-compressor; C-combustion chamber; D-gas turbine; E -regenerator; F-heating network heater; G-LNG vaporizer; H-natural gas expansion turbine; I-filter; J-generator.

[0064] The connection in the above system is a known technology, and the present invention will not be described in detail here.

[0065] System process description:

[0066] LNG is compressed to state 2 through booster pump A (this process is unnecessary when LNG has sufficient pressure); in LNG vaporizer G, LNG is heated to become superheated natural gas 3; and then reaches low pressure through expansion turbine H , Normal temperature state 4 / 5 (there is expansion turbine when the natural gas delivery pressure is subcritical pressure); then part of the natural gas 5 enters the combustion chamber C of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com