Method and installation for producing thin flat products

A manufacturing method and equipment technology, applied in the direction of manufacturing tools, metal processing equipment, workpiece surface treatment equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

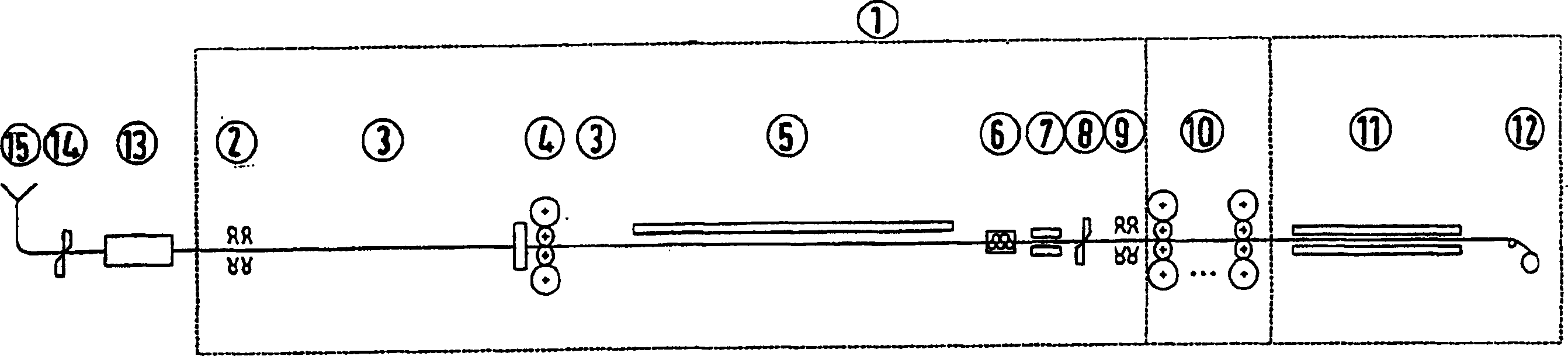

[0027]The production equipment includes a casting machine 15 for producing thick continuous casting slabs, medium-thick continuous casting slabs or thin slabs, a shearing machine 14 for dividing the slab into billets, and a heating and cold charging or hot charging A furnace for soaking continuous casting slabs or thin slabs to the rolling temperature 13, a high-pressure water descaling machine for descaling heated or soaked continuous casting slabs 2, and a conveyor in the rolling direction Roller table 3 for slabs or rolling pieces that swings the intermediate strip during intermediate cooling, a single-stand or double-stand and used to roll continuous cast slabs into rough strips in at least two rolling stages Rough rolling mill 4, a roll table section with a reversible heat-insulating cover 5, a straightening device for straightening the rough strip 6, a set for the entire width and length of the rough strip Induction heating device that can adjust the heating of the rough-rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com