Equipment for continuously producing adhesive non-woven fabric web

A technology of non-woven fabrics and equipment, applied in the directions of non-woven fabrics, melt spinning, textiles and papermaking, etc., can solve the problems of irregular strength, ductility and air permeability of non-woven fabrics, unsatisfactory performance, monofilament density and mesh size Problems such as uneven width, etc., to achieve the effect of effective conveying reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

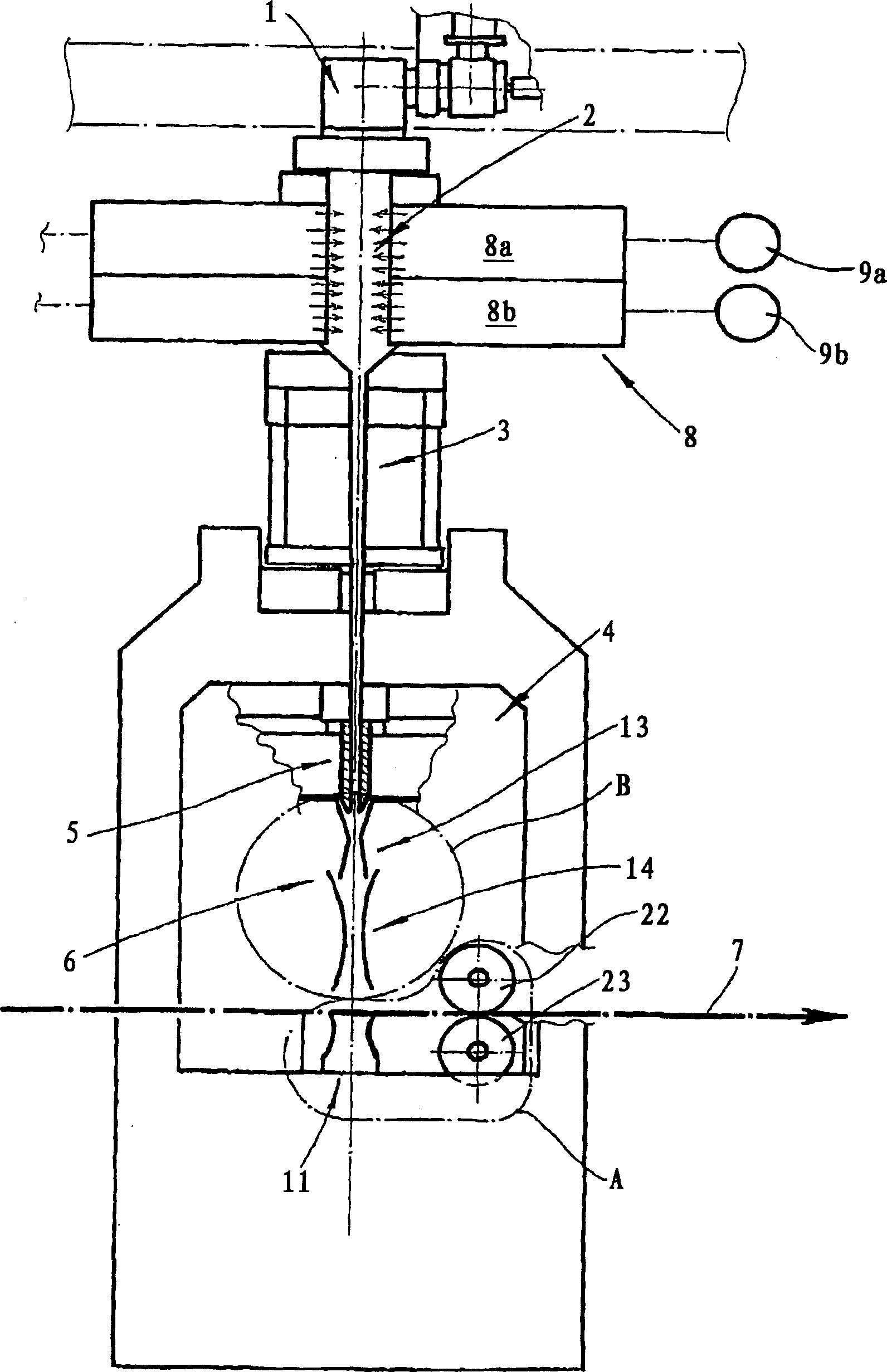

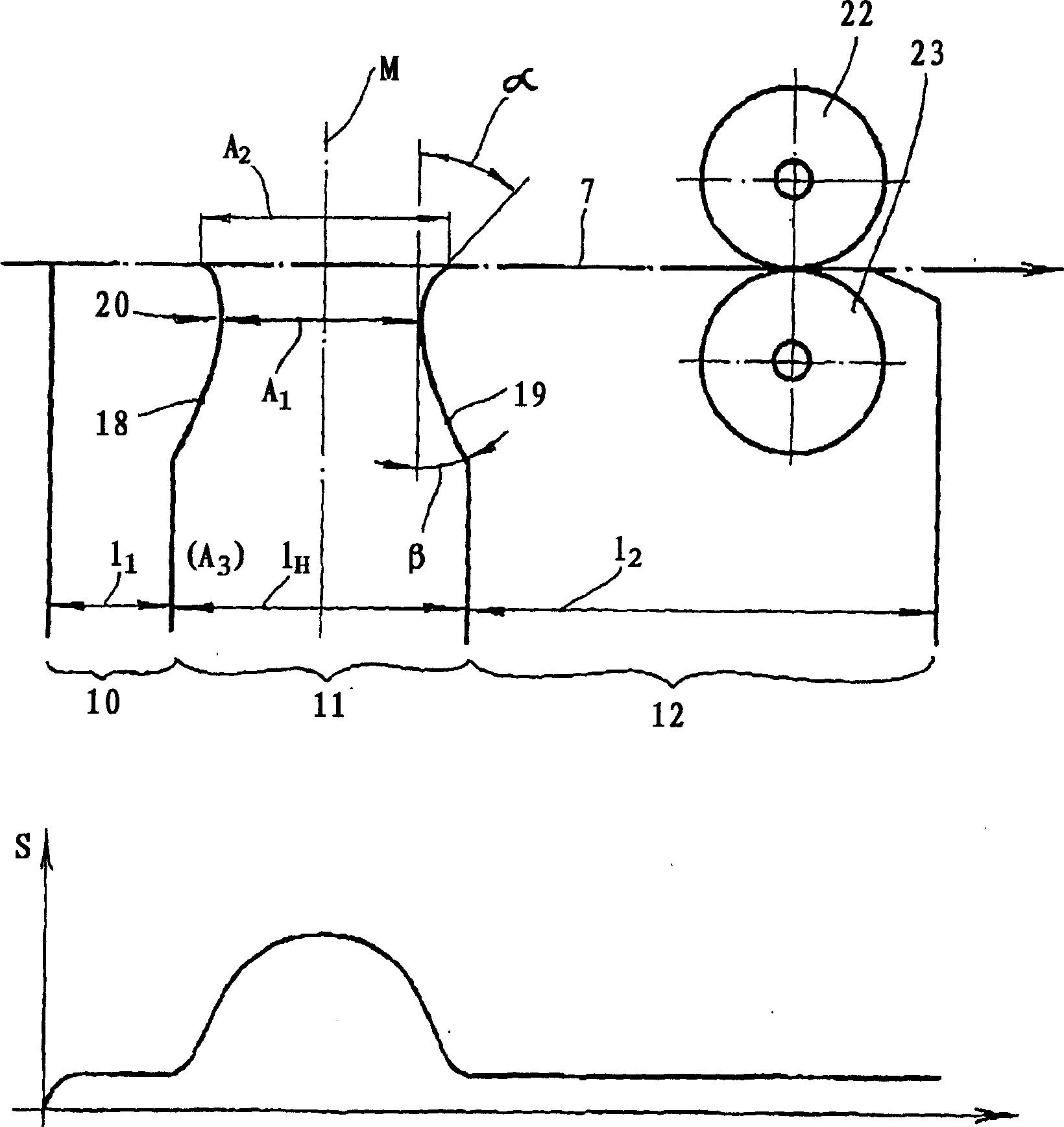

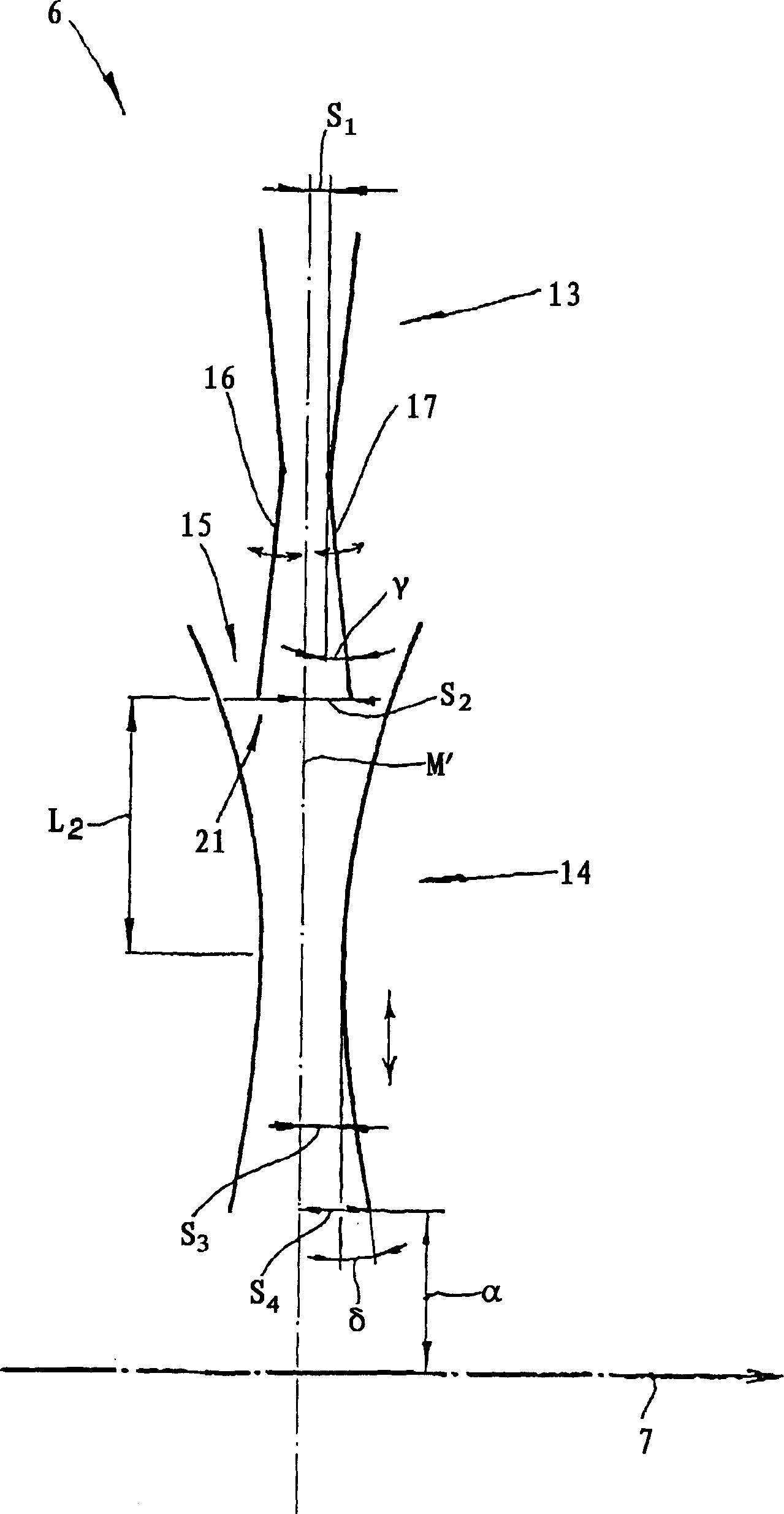

[0021] The drawing shows a plant for the continuous production of spunbonded nonwoven webs from aerodynamically stretched thermoplastic monofilaments. The device has a spinning head 1 and a cooling chamber 2 arranged below the spinning head 1, into which process air can be supplied for cooling the filaments. Adjoining the cooling chamber 2 is an intermediate channel 3 , behind which is a stretching unit 4 with a pull-down channel 5 . A laying unit 6 is connected to the drop-down channel 5 . A stacking device in the form of a continuously moving stacking mesh belt 7 for stacking monofilaments into a spunbond nonwoven fabric web is provided below the laying unit 6 .

[0022] exist figure 1 The cooling chamber 2 according to the invention and the air supply compartment 8 arranged next to the cooling chamber 2 can be seen in the drawing. In the exemplary embodiment shown, the air intake compartment 8 is divided into an upper intake compartment segment 8a and a lower intake comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com